Long-distance double-layer pipe inner pipe leakage point positioning method

A positioning method and double-layer tube technology, which can solve the problems of inapplicable hydrogen pipeline leak point location by detecting the appearance of fluid at the leak point, pipeline system, measuring device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0085] The present invention provides a method for locating leaks in long-distance double-layer pipes, the method comprising the following steps:

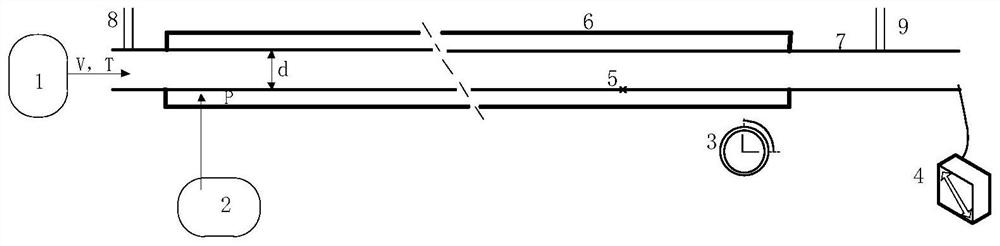

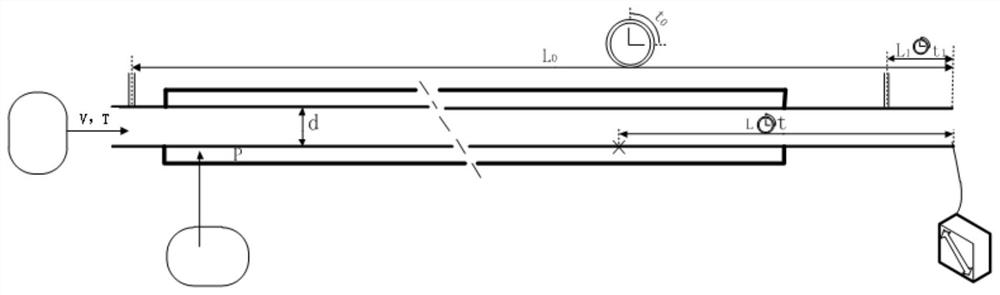

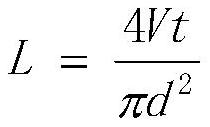

[0086] Step (1), setting up and installing equipment for locating the leakage point of the long-distance double-layer pipe

[0087] Such as figure 1 As shown, the equipment used to locate the leak point of the long-distance double-layer pipe includes: air source 1, helium gas source 2, stopwatch 3 and helium mass spectrometer 4. The long-distance double-layer pipe includes an outer pipe 6 and an inner pipe 7, and the air source 1 is connected with one end of the inner pipe 7 of the pipeline under inspection, and is used to provide the inner pipe 7 with air with various flow and temperature characteristics; the helium The gas source 2 is connected to the wall of the outer tube 6 of the pipeline un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com