Garbage incinerator spray tower and garbage incinerator

A technology for waste incinerators and furnace spray towers, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as inability to circulate liquid cooling, inability to automatically adjust pH, and inability to adjust the contact time between flue gas and spray liquid, etc. , to avoid hardening and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

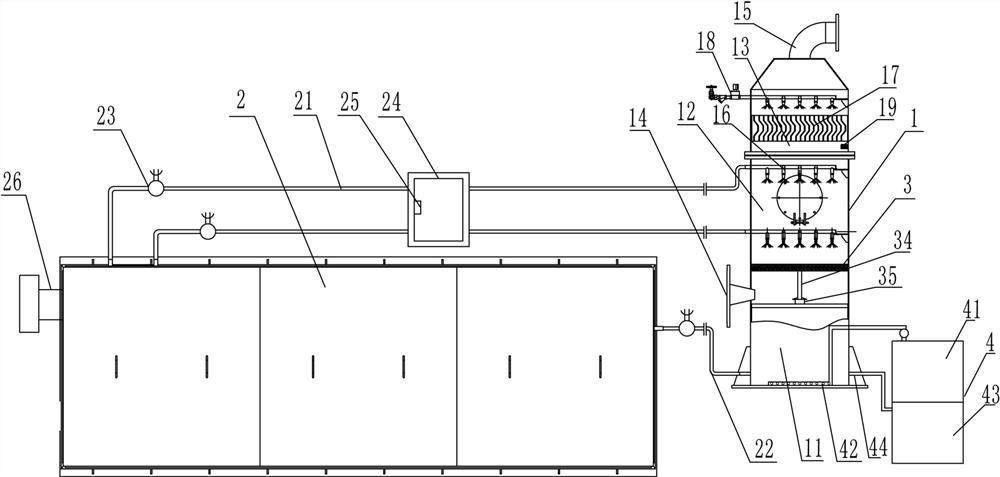

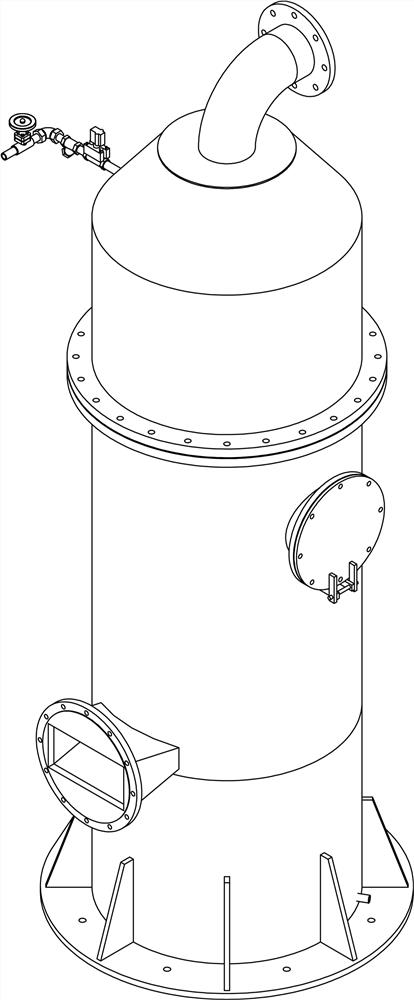

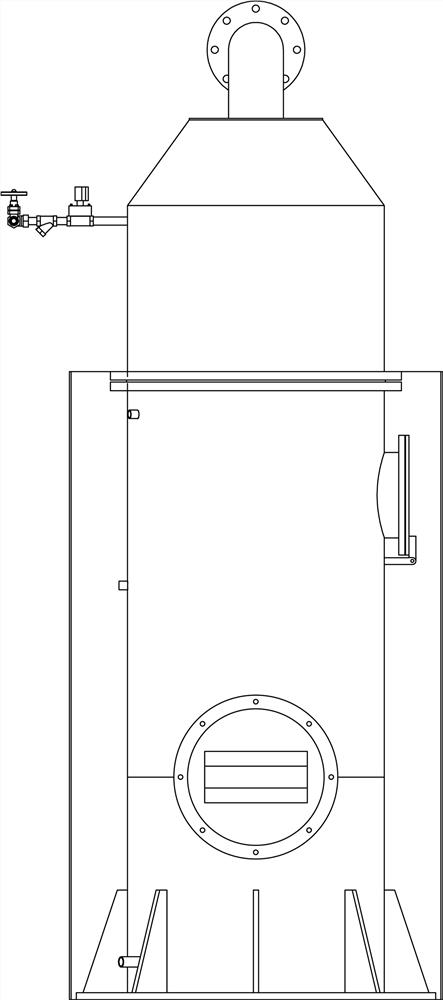

[0032] Such as Figure 1~Figure 6 Among them, a garbage incinerator spray tower, including a hollow tower body 1, the top of the tower body 1 is provided with a flue gas outlet 15; the inside of the tower body 1 includes a sedimentation tank 11 at the bottom, a reaction zone 12 at the middle and a removal tank at the top. The mist area 13; the reaction area 12 is provided with a spray mechanism 16; the mist removal area 13 is provided with a defogger 17 and a flusher 18; The inner wall of the tower body 1 is provided with a packing layer 3; one side of the tower body 1 is provided with a lye pool 2, and the lye pool 2 is connected with the tower body 1 through a circulation pipeline; Mechanism 4 is connected with lye pool 2 by pipeline.

[0033] Preferably, the packing layer 3 includes a double-layer structure in which a fixed layer 31 and a rotating layer 32 are connected; the centers of the fixed layer 31 and the rotating layer 32 are connected in rotation through a bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com