Socket-and-spigot PP inner wall reinforced concrete pipe

A reinforced concrete pipe, socket-type technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipes, etc., can solve the problems of inconvenience, reduced cutting accuracy, low cutting efficiency, etc., and achieve convenient and economical disassembly and installation. The effect of cutting time and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

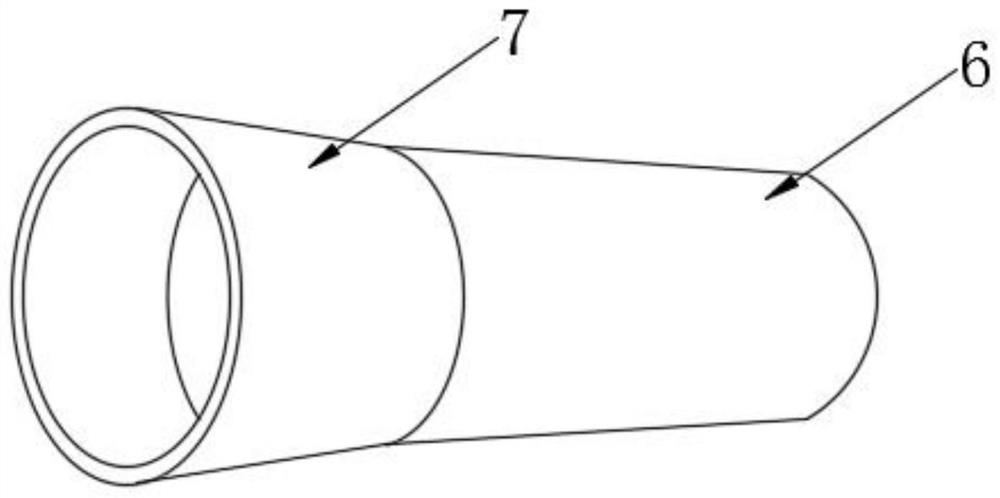

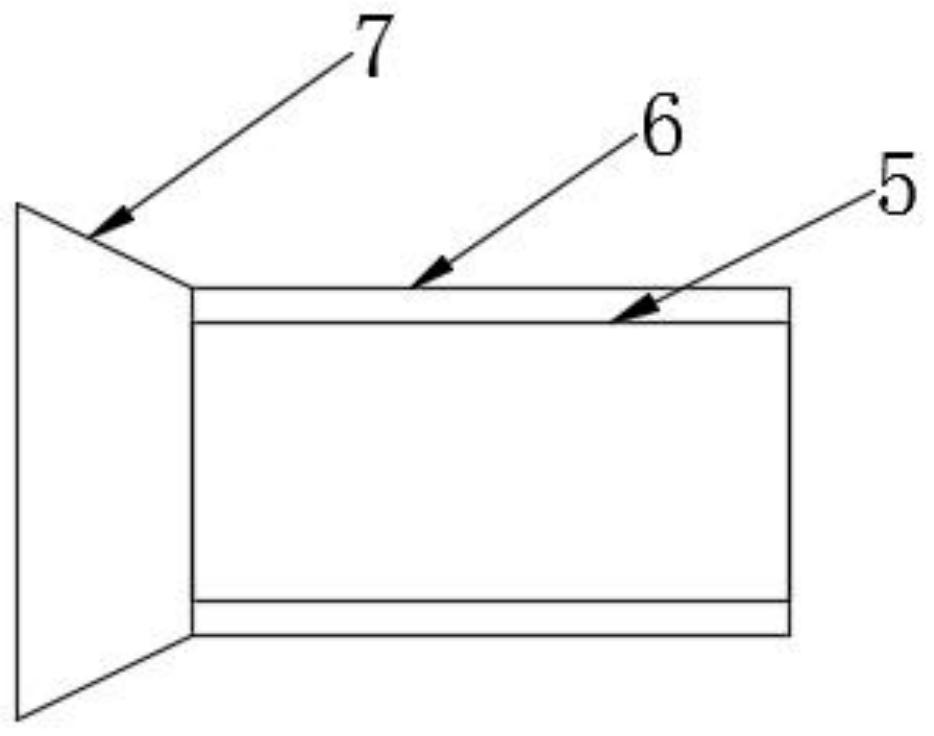

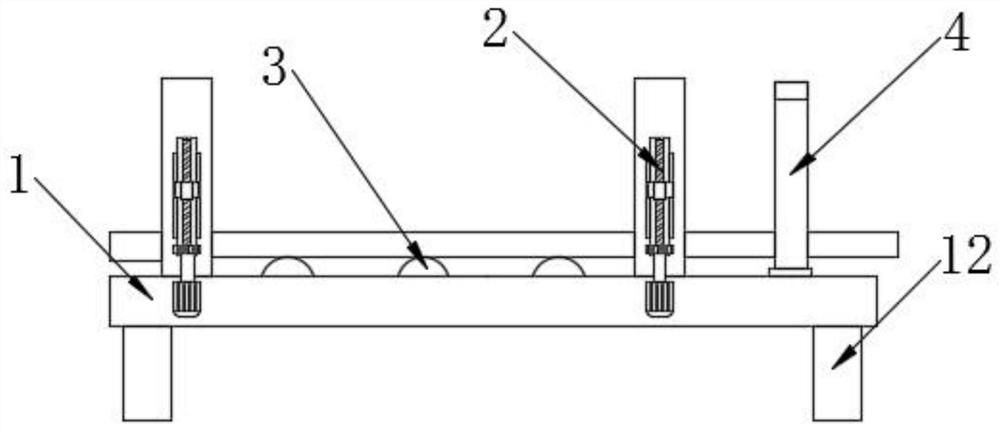

[0058] A socket type PP inner-wall reinforced concrete pipe, comprising a PP layer 5, the outside of the PP layer 5 is wrapped with a concrete layer 6, one end of the concrete layer 6 is fixed with a steel ring 7, and the cross-sectional shape of the steel ring 7 is an equilateral trapezoid;

[0059] The preparation method of the socket type PP inner wall reinforced concrete pipe is as follows:

[0060] Step 1. Preparation of PP pipe:

[0061] S1. Weigh the following raw materials in parts by weight: 20 parts of light calcium carbonate, 15 parts of yttrium nitride powder, 50 parts of high-density polypropylene, 10 parts of magnesium oxide, 20 parts of aluminum hydroxide, and 22 parts of polyolefin elastomer POE;

[0062] S2, dissolving yttrium nitride powder and light calcium carbonate in water, and obtaining powder A through processes such as homogenization, concentration, and spray drying;

[0063] S3, mixing powder A, high-density polypropylene, magnesium oxide, aluminum h...

Embodiment 2

[0072] A socket type PP inner-wall reinforced concrete pipe, comprising a PP layer 5, the outside of the PP layer 5 is wrapped with a concrete layer 6, one end of the concrete layer 6 is fixed with a steel ring 7, and the cross-sectional shape of the steel ring 7 is an equilateral trapezoid;

[0073] The preparation method of the socket type PP inner wall reinforced concrete pipe is as follows:

[0074] Step 1. Preparation of PP pipe:

[0075] S1. Weigh the following raw materials in parts by weight: 25 parts of light calcium carbonate, 17 parts of yttrium nitride powder, 55 parts of high-density polypropylene, 12 parts of magnesium oxide, 22 parts of aluminum hydroxide, and 24 parts of polyolefin elastomer POE;

[0076] S2, dissolving yttrium nitride powder and light calcium carbonate in water, and obtaining powder A through processes such as homogenization, concentration, and spray drying;

[0077] S3, mixing powder A, high-density polypropylene, magnesium oxide, aluminum h...

Embodiment 3

[0086] A socket type PP inner-wall reinforced concrete pipe, comprising a PP layer 5, the outside of the PP layer 5 is wrapped with a concrete layer 6, one end of the concrete layer 6 is fixed with a steel ring 7, and the cross-sectional shape of the steel ring 7 is an equilateral trapezoid;

[0087] The preparation method of the socket type PP inner wall reinforced concrete pipe is as follows:

[0088] Step 1. Preparation of PP pipe:

[0089]S1. Weigh the following raw materials in parts by weight: 30 parts of light calcium carbonate, 20 parts of yttrium nitride powder, 60 parts of high-density polypropylene, 15 parts of magnesium oxide, 24 parts of aluminum hydroxide, and 25 parts of polyolefin elastomer POE;

[0090] S2, dissolving yttrium nitride powder and light calcium carbonate in water, and obtaining powder A through processes such as homogenization, concentration, and spray drying;

[0091] S3, mixing powder A, high-density polypropylene, magnesium oxide, aluminum hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com