Cement conveying equipment with anti-solidification vibration mechanism

A vibration mechanism and conveying equipment technology, which is applied in the direction of conveyors, conveyor objects, cement mixing devices, etc., can solve the problems of ineffective prevention of cement solidification, affecting normal cement transportation, and low cement transportation efficiency, so as to prevent cement solidification , It is not easy to solidify, and the effect of improving the conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

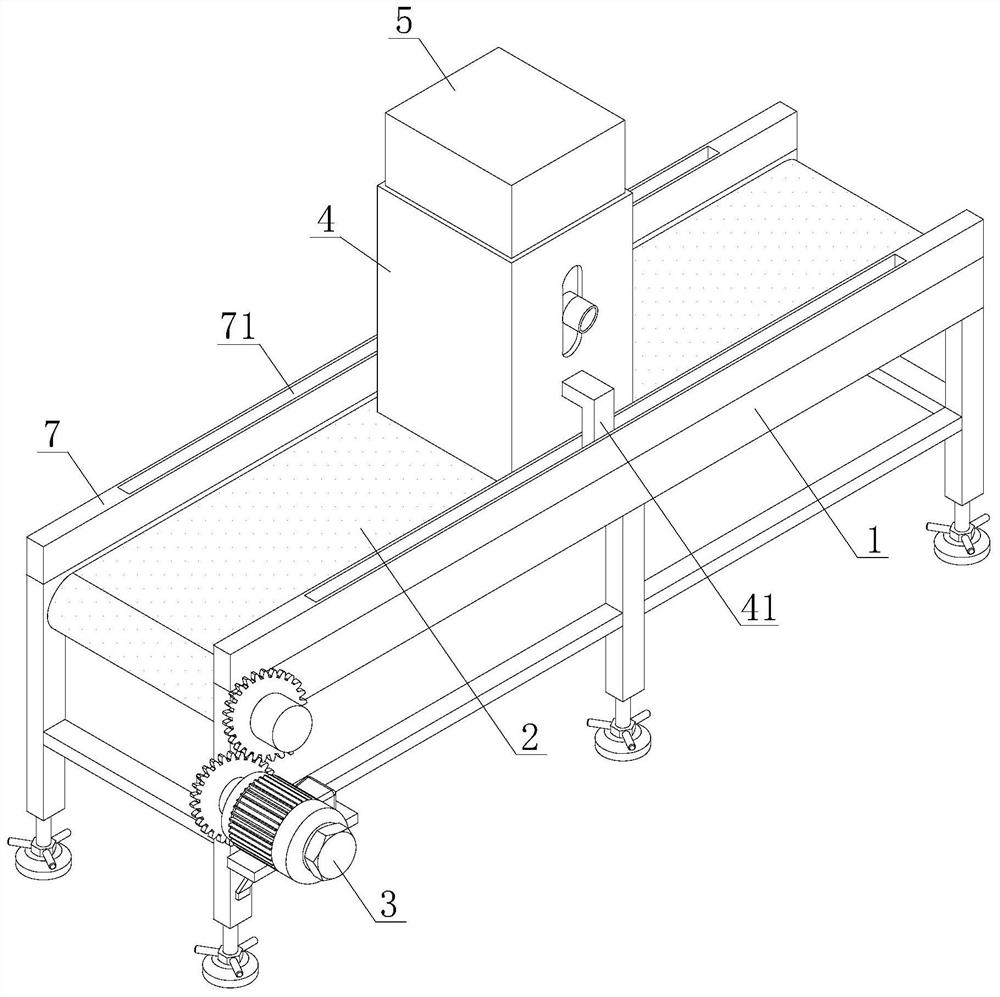

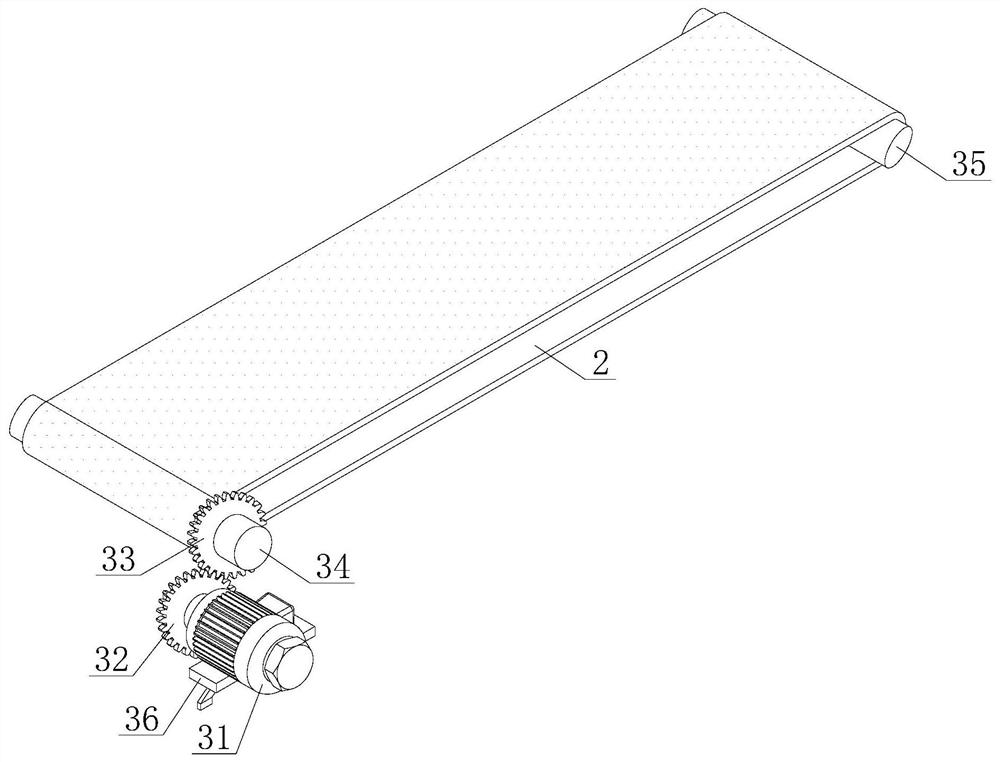

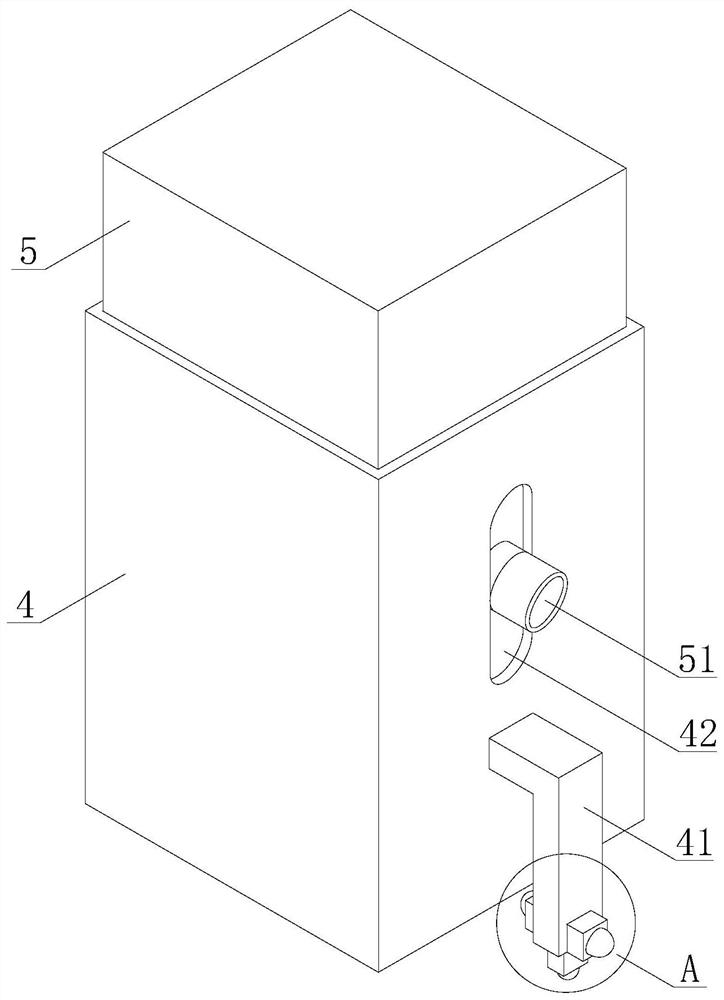

[0031] refer to figure 1 , a cement conveying device with an anti-solidification vibration mechanism, including a frame 1, a conveyor belt 2 is arranged on the upper end of the frame 1, and the conveyor belt 2 is transmitted by a drive mechanism 3, and the drive mechanism 3 drives the conveyor belt 2 to rotate, and the conveyor belt 2 is rotated by the rotating The conveyor belt 2 can drive the conveying box 4 to move steadily and smoothly on the guide seat 7 under the guidance of the guiding mechanism 41. The movement of the conveying box 4 can make the cement box 5 also move accordingly, and the cement box 5 is transported through the moving cement box. , conveying box 4 is installed on the conveyor belt 2, and the upper end of conveying box 4 is provided with cement box 5, and cement box 5 is positioned at the inner side of conveying box 4, and the lower end of cement box 5 is provided with mud discharge pipe 51, and mud discharge pipe 51 passes through The delivery box 4 e...

Embodiment 2

[0037] refer to Figure 8 , a cement conveying device with an anti-solidification vibration mechanism, including a frame 1, a conveyor belt 2 is arranged on the upper end of the frame 1, and the conveyor belt 2 is transmitted by a drive mechanism 3, and the drive mechanism 3 drives the conveyor belt 2 to rotate, and the conveyor belt 2 is rotated by the rotating The conveyor belt 2 can drive the conveying box 4 to move steadily and smoothly on the guide seat 7 under the guidance of the guiding mechanism 41. The movement of the conveying box 4 can make the cement box 5 also move accordingly, and the cement box 5 is transported through the moving cement box. , conveying box 4 is installed on the conveyor belt 2, and the upper end of conveying box 4 is provided with cement box 5, and cement box 5 is positioned at the inner side of conveying box 4, and the lower end of cement box 5 is provided with mud discharge pipe 51, and mud discharge pipe 51 passes through The delivery box 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com