Self-inflating sealing ring, cylinder section clamping tool and inner wall protection and local oxidation method

A sealing ring and self-inflating technology, which is applied in the field of inner wall protection and local oxidation, self-inflating sealing ring, barrel section clamping tooling, can solve the problems of difficult installation and inability to disassemble, and achieve simple, non-dangerous and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A self-inflating sealing ring.

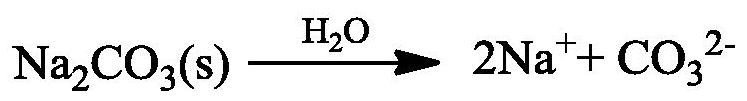

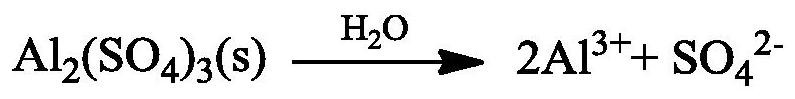

[0065] The production material is fluorine rubber, and 100 grams of solid aluminum sulfate and 60 grams of potassium carbonate are stored inside. The inner diameter of the sealing ring is 8 meters when it is not inflated.

[0066] When in use, inject a small amount of water into the feed port of the seal ring to seal the feed port of the seal ring. Aluminum sulfate and potassium carbonate react with gas to inflate and expand the seal ring.

Embodiment 2

[0068] A clamping tool inside a large cylinder section.

[0069] Includes: a self-inflating seal and a protective barrel section.

[0070] A self-inflating sealing ring is made of silica gel, and 100 grams of solid aluminum sulfate and 50 grams of sodium carbonate are stored inside. The inner diameter of the sealing ring is 6 meters when it is not inflated, and the outer diameter of the sealing ring is 6.1 meters when it is inflated.

[0071] The protective cylinder section is made of polypropylene, the outer diameter D2 of the protective cylinder section is 6 meters, and the height H2 is 3 meters. (The inner diameter D1 of the large cylinder section is 6.05 meters, and the height H1 is 3 meters)

Embodiment 3

[0073] A method for protecting the inner wall of a large cylinder section.

[0074] The inner diameter D1 of the large cylinder section is 5 meters, and the height H1 is 3 meters.

[0075] The internal clamping tool of the large cylinder section is used, in which the self-inflating sealing ring is made of silica gel, and 745 grams of solid aluminum nitrate and 336 grams of ammonium carbonate are stored inside. The diameter is 5.05 meters.

[0076] The protective cylinder section is made of polypropylene, the outer diameter D2 of the protective cylinder section is 4.9 meters, the height H2 is 3 meters, and the inner diameter of the protective cylinder section is 4.8 meters.

[0077] Use a crane to lift the protective tube section, and put it inside the large tube section, and the height is even.

[0078] Install two self-inflating sealing rings, the two self-inflating sealing rings are installed in the gap between the inner wall of the large cylinder section and the outer wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com