Apparatus and method for reduction of particle contamination by bias voltage

A bias voltage, voltage source technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as being easily hit by ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

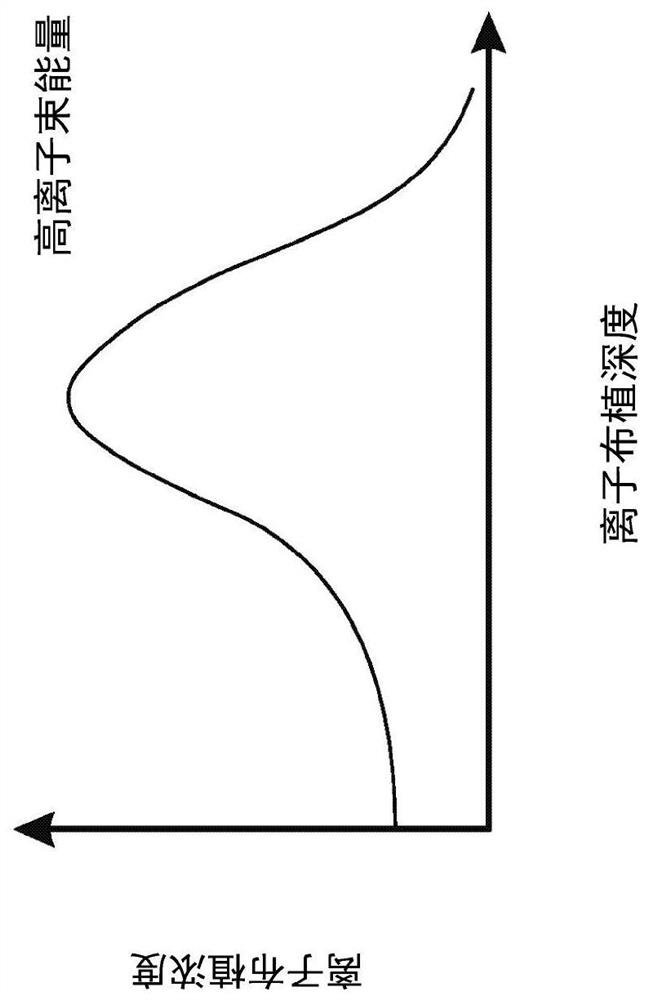

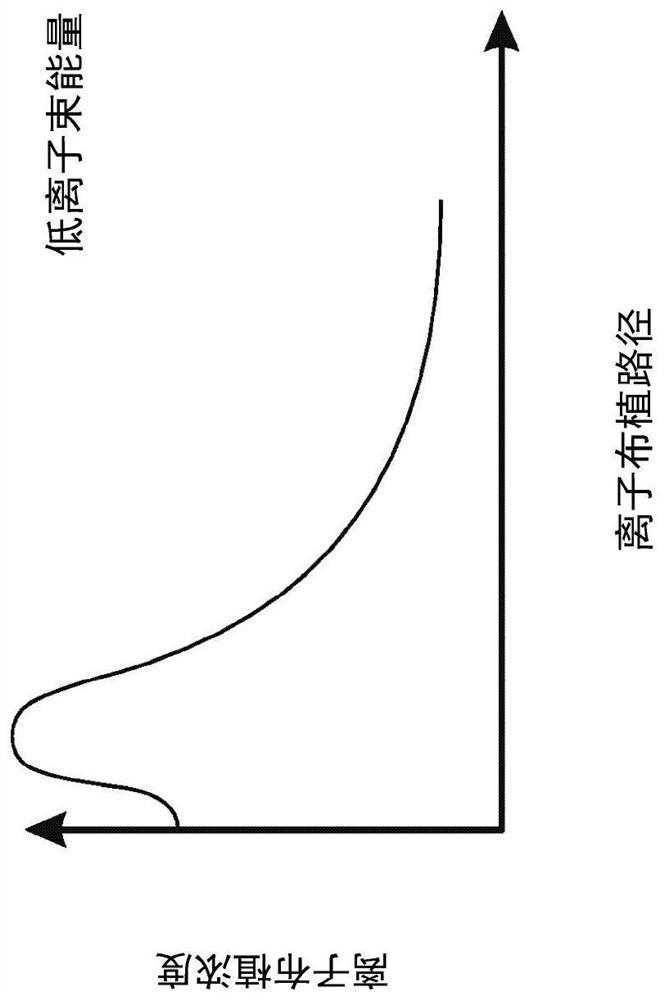

[0059] The physical mechanism of the problem to be solved by the present invention can be briefly described as follows. The ion implantation depth (doping depth) is proportional to the ion beam energy (doping energy), and the ion implantation concentration (doping concentration) is correspondingly proportional to the ion implantation current. refer to Figure 1A to Figure 1B Shows how ion implant depth and ion implant concentration vary with different ion beam energies. Reasonably, when the energy of the ion beam is low enough, the distribution of implanted ions will be largely concentrated in the vicinity of the surface of the implanted component. Therefore, not only the shallower part of the implanted component is strongly damaged due to the presence of a large number of implanted ions, but also a certain number of particles are stripped from the implanted component and float into the vacuum environment where the wafer is held for ion implantation . For example, the exfol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com