Preparation method of porous film for battery, porous film, battery diaphragm and battery

A technology of porous film and battery diaphragm, which is applied in the field of porous film, battery diaphragm and battery, can solve the problems affecting the air permeability and use effect of the battery, the safety and service life of the battery, etc., and is suitable for automatic control, and the preparation method is simple and easy , good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

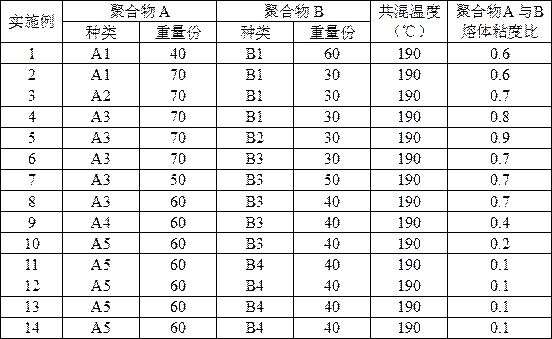

[0074] According to the raw materials and formulations shown in Table 1, the porous film was prepared with reference to the following preparation method.

[0075] Step 1: Blending the corresponding types and parts by weight of polymer A and polymer B at the blending temperature shown in Table 1, extruding and casting to make a blended film with a thickness of 10 microns;

[0076] Step 2: Soak the above blended film in 0.01 mol / L sulfuric acid aqueous solution for 48 hours, take it out and dry it at 60° C. to obtain a porous film.

[0077] Table 1:

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com