Alloy plate bending device for plate processing

A bending device and plate processing technology, applied in the field of plate processing, can solve the problems of poor appearance of alloy plates, wear of contact surfaces, influence on use, etc., to accelerate the degree of wear, improve the degree of lubrication, and avoid excessive temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

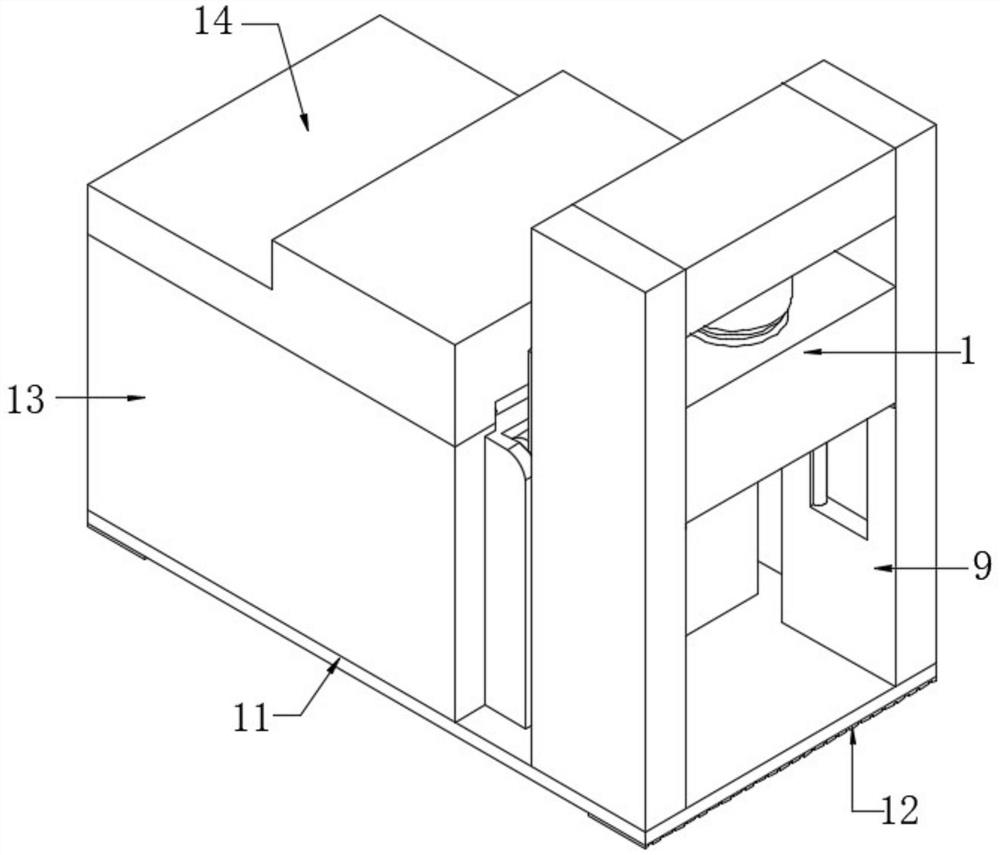

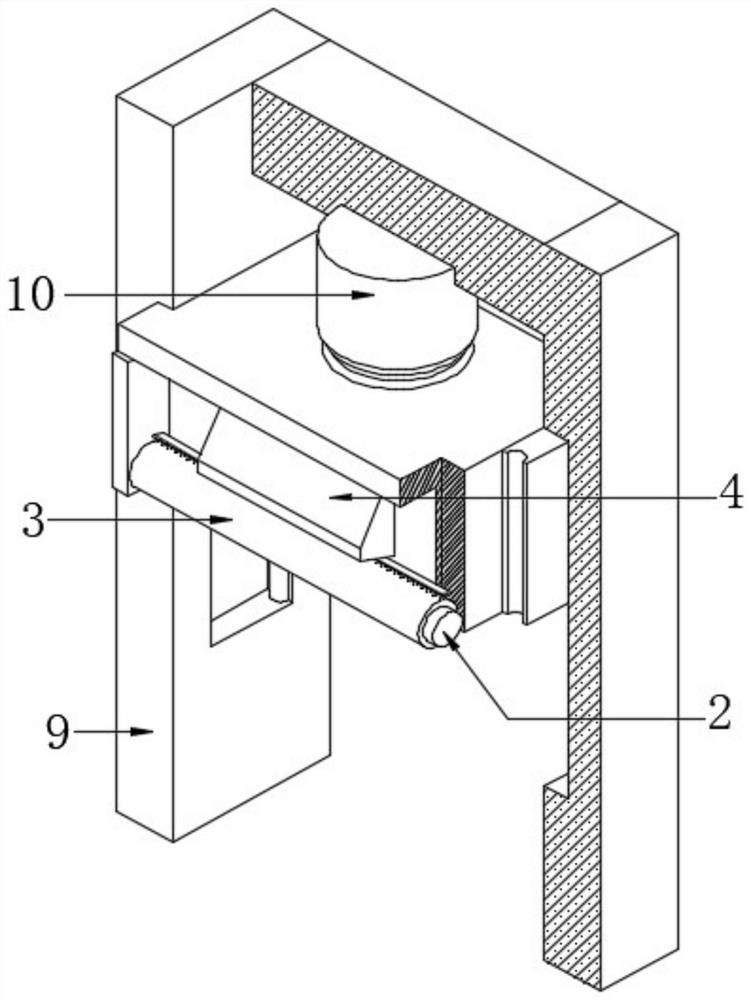

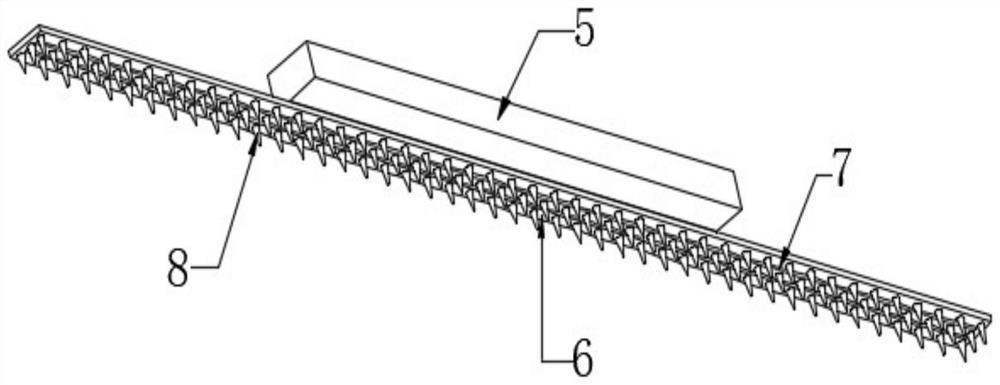

[0028] refer to Figure 1-5 , an alloy plate bending device for plate processing, comprising a pressure box 1, an extrusion shaft 2 is rotatably connected between the inner walls on both sides of the pressure box 1 through bearings, and the outer wall of the extrusion shaft 2 is connected with a sleeve 3 through bolts, There is a groove on the pressure tank 1, and the inner wall of the groove is connected with the oil storage tank 4 by bolts, and the oil storage tank 4 is provided with an oil overflow seat 5, and the oil overflow seat 5 and the inner wall of the oil storage tank 4 are connected by a conduit , the lower outer wall of the oil spill seat 5 is connected with an oil equalizing plate 6 by bolts, an oil delivery conduit is arranged between the oil equalizing plate 6 and the oil overflow seat 5, and two oil outlet grooves are provided on the lower outer wall of the oil equalizing plate 6 7. Both sides of the two oil outlet grooves 7 are provided with brushes 8, and th...

Embodiment 2

[0037] refer to Figure 6 , an alloy plate bending device for plate processing. Compared with Embodiment 1, the present embodiment has a liquid collection tank 25 connected by bolts between the inner walls of both sides of the side seat 9, and the bottom outer wall of the liquid collection tank 25 is connected to the base plate 11. The outer wall of the upper side is connected by bolts, and a collection pool 26 is provided on the liquid collection box 25, and an inclined plate is provided on one side of the liquid collection box 25, and a liquid flow groove 27 is provided on the inclined plate.

[0038] When in use, during the operation of the device, due to the increase of lubricating oil on the outer wall of the sleeve 3, there will be dripping, and the dripping lubricating oil will eventually fall into the liquid flow groove 27, and then flow into the collection pool after being concentrated through the liquid flow groove 27 26, in order to facilitate the collection and reu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com