Vacuum brazing method for slender weld seam of hole-shaft matching parts

A technology of hole shaft matching and brazing method, which is applied in the direction of welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that there are many unwelded areas of the brazing material and the requirements of the weld seam are not met, so as to ensure the quality of brazing, Easy to assemble and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will be combined with a preferred embodiment of the present invention described in conjunction with the accompanying drawings, the technical solution in a preferred embodiment of the present invention is clearly and completely described.

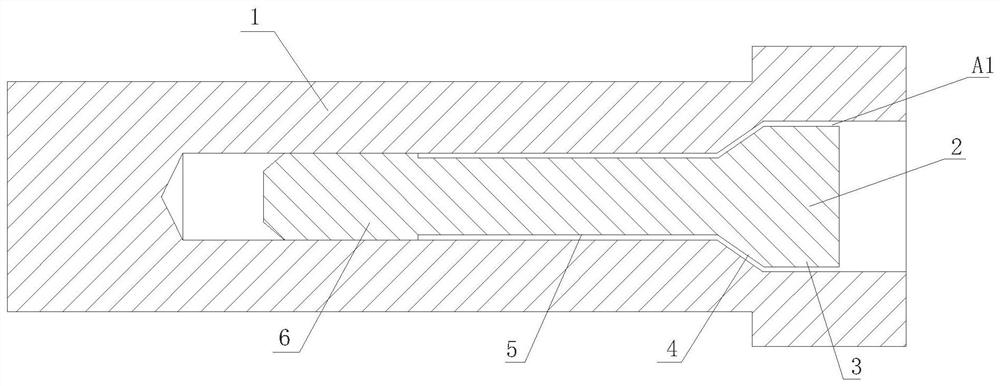

[0037] Figure 1 Schematic diagram of the assembly of the hole type 1 and the shaft part 2, the shaft part 2 includes a large diameter part 3, a small diameter part 5 and a cone face connecting the two 4, the large diameter part 3 and the small diameter part 5 and the hole part 1 have a unilateral welding gap of 0.05-0.1cm, the front end of the small diameter part 5 has a clamping part that can be tightly matched with the hole type 1 6, the vacuum brazing method of the slender weld of the aperture shaft with the part includes the following steps,

[0038] 1. Verification parts:

[0039] (1) spare parts: prepare hole profile 1 and shaft profile 2, nickel-based alloy powder brazing, binder, nickel foil thickness of 0.05cm; in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com