Wine brewing workshop

A workshop and rack technology, applied in the field of brewing workshops, can solve the problems of easy random scattering of discarded grains, easy overflow of yellow water, and rolling of discarded grains, so as to avoid random stacking, prevent pollution, and clean the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

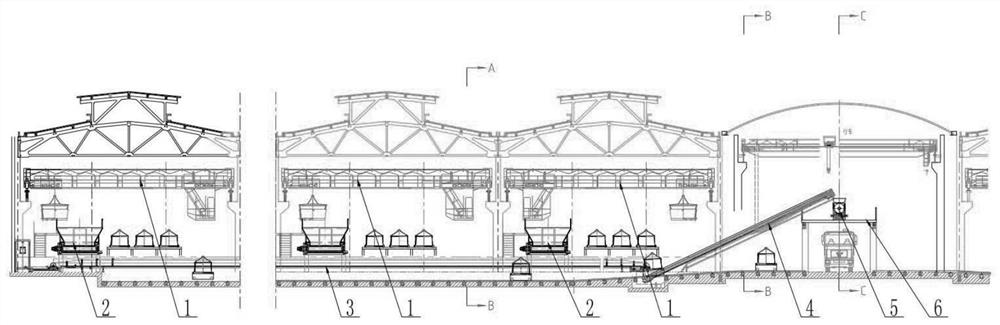

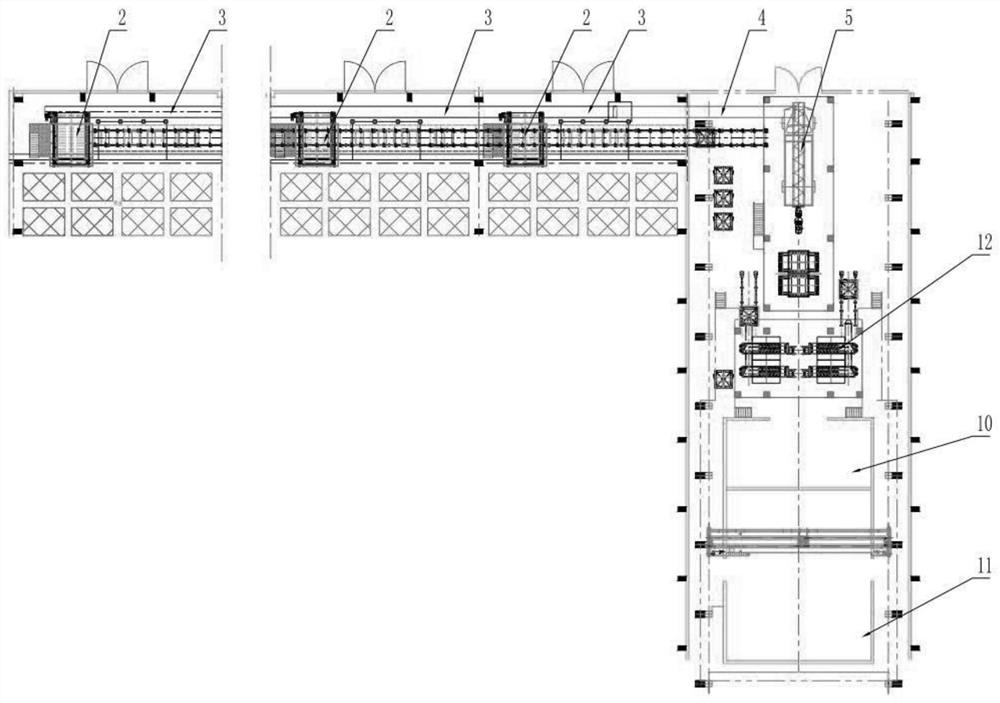

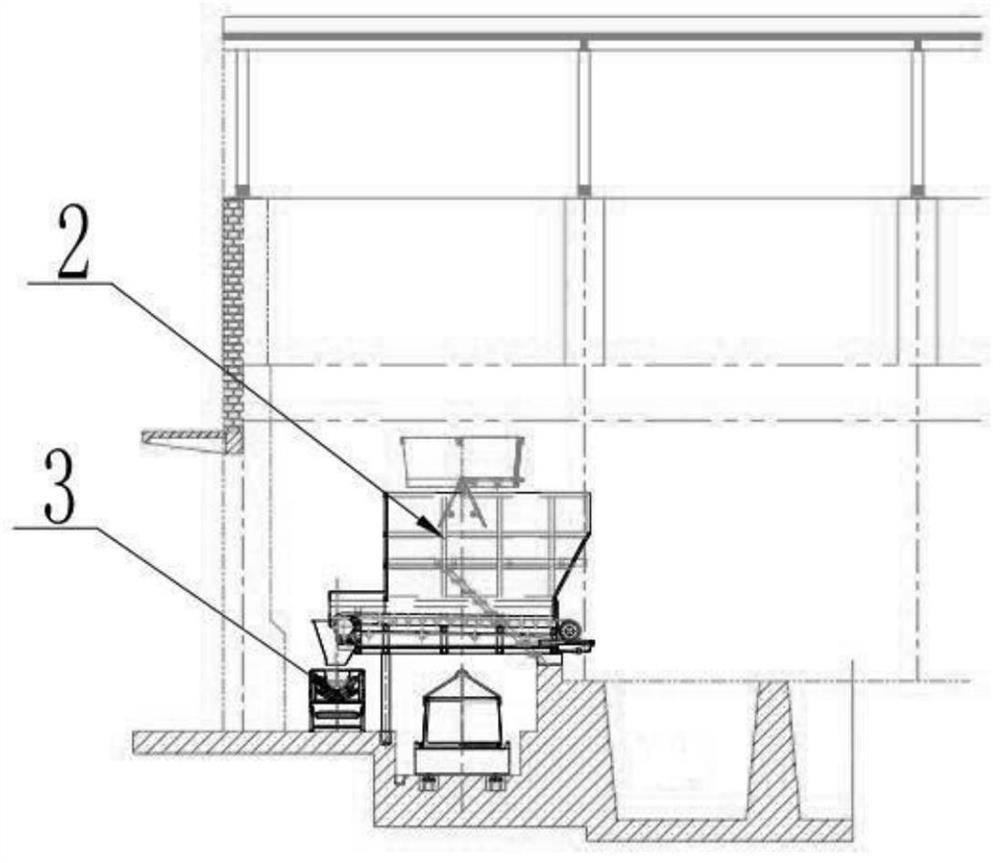

[0075] Such as Figure 1 to Figure 5 As shown, a kind of brewing workshop provided by the present invention includes a waste disposal system for directly processing waste grains and a waste grain feeding crane 1 for lifting and retrieving the retort body. During the brewing process, after the grain is cooked, The cooked retort is hoisted and transported to the waste disposal system through the dross dumping and feeding truck 1, so that the dregs in the retort can be directly poured onto the dregs disposal system, so that the dregs disposal system can directly control the liquor production process The disposal of the discarded grains can not only avoid random stacking of the discarded grains, but also make the brewing workshop more clean and tidy.

[0076] The dregs disposal system includes sequentially docked dela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com