a brewery

A workshop and rack technology, applied in the field of brewing workshops, can solve the problems of easy scattering of discarded dregs, easy overflow of yellow water, and rolling of discarded dregs, etc., to achieve the effect of cleaning the workshop, preventing pollution and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

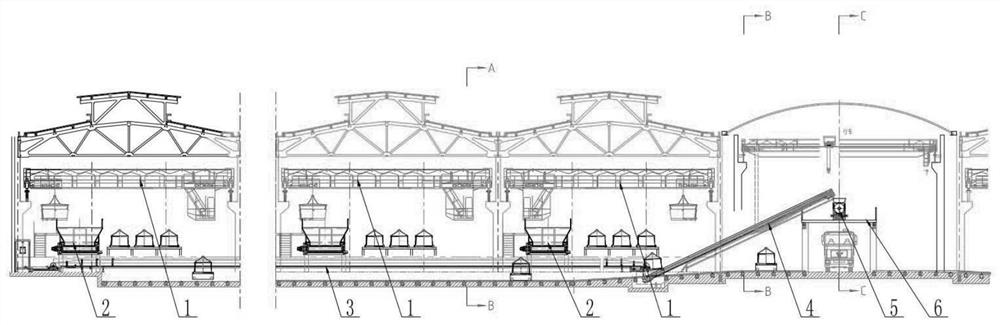

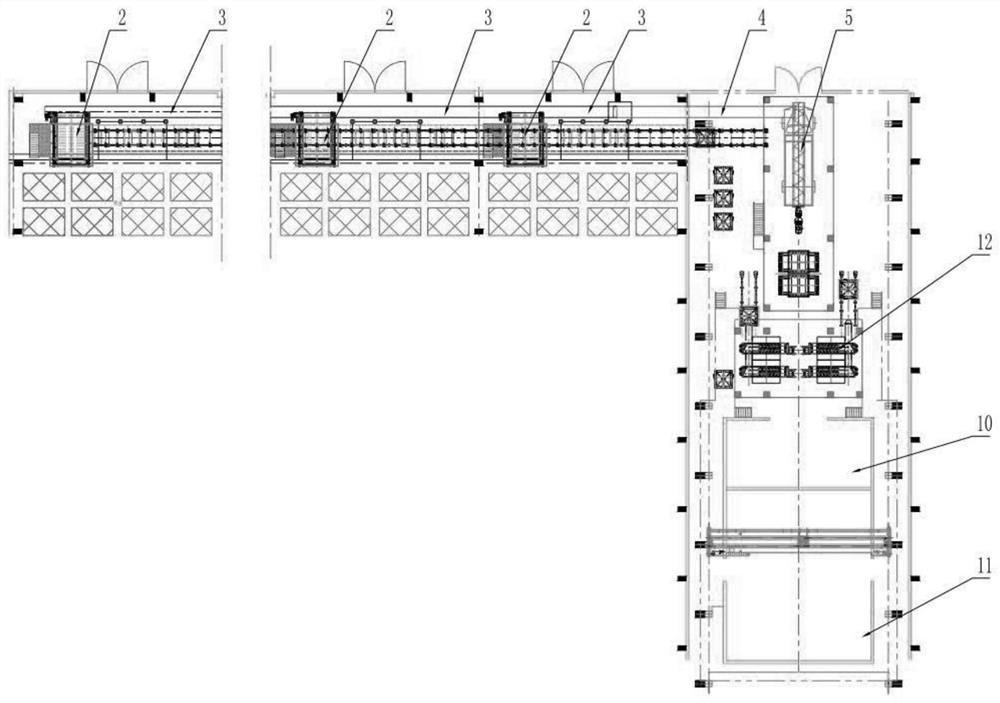

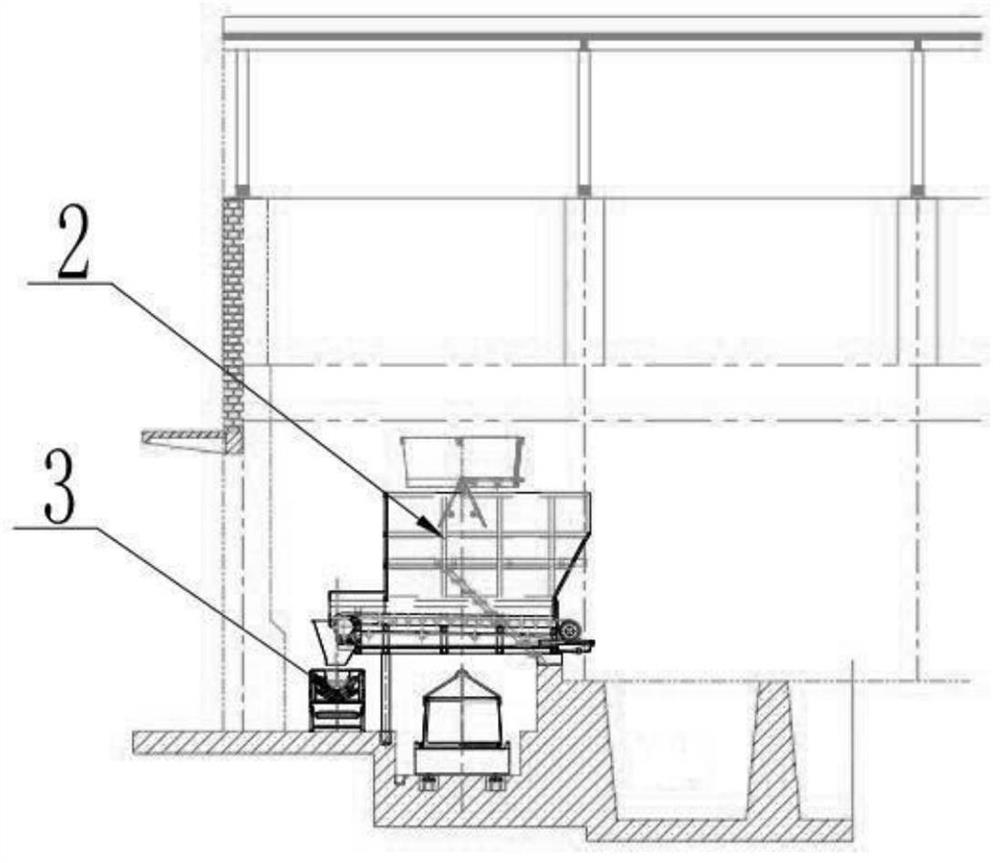

[0075] like Figure 1 to Figure 5 As shown in the figure, a brewing workshop provided by the present invention includes a waste waste disposal system for directly processing the waste waste and a waste waste loading crane 1 for hoisting the retort. During the brewing process, when the grain is cooked, The finished retort is hoisted to the disposal system by the waste disposal and loading crane 1, so that the waste in the retort can be directly dumped on the disposal system, so that the disposal system can directly affect the process of liquor production. It can not only avoid the random stacking of the waste, but also make the brewing workshop more clean and tidy.

[0076] The waste disposal system includes a delay conveyor 2, a U-shaped belt conveyor 3, an inclined belt conveyor 4, and a loading screw conveyor 5 that are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com