Borosilicate glass curing base material as well as preparation method and application thereof

A borosilicate glass and base material technology, which is applied in the field of borosilicate glass solidified base material and its preparation, can solve problems such as potential safety hazards, and achieve the effects of preventing glass devitrification, minimizing volume, and high silicon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

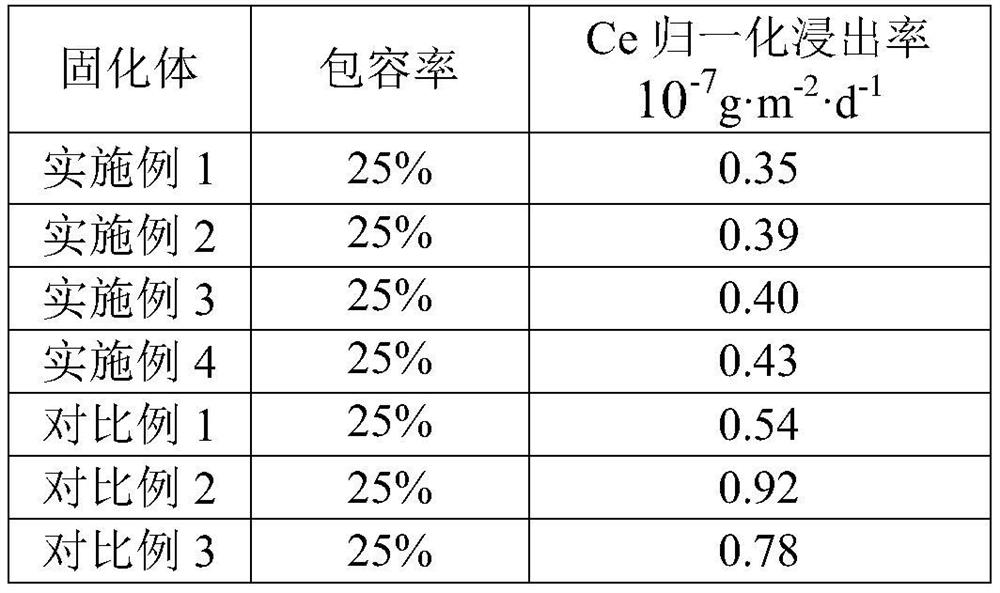

Examples

preparation example Construction

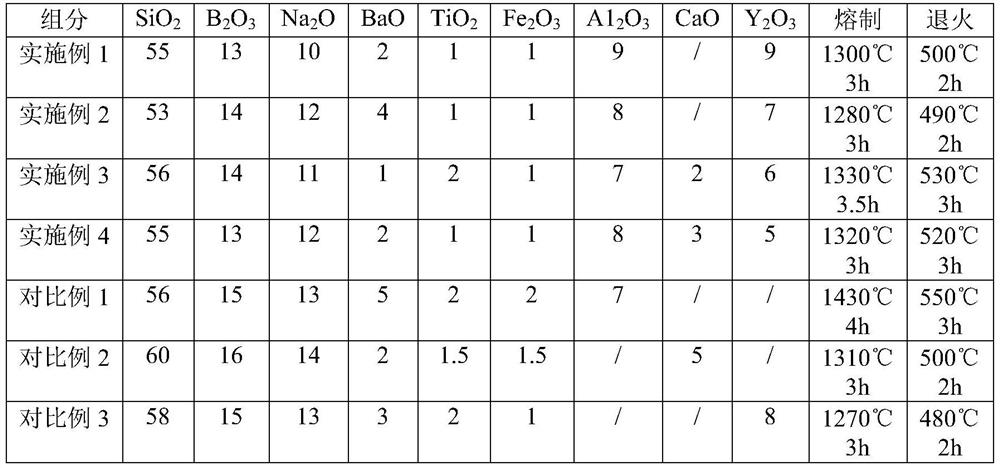

[0035] The present invention also provides a method for preparing a borosilicate vitrified substrate, comprising the following steps:

[0036] The recipe amount of SiO 2 , B 2 o 3 、Al 2 o 3 、Na 2 O, CaO, BaO, TiO 2 , Y 2 o 3 and Fe 2 o 3 After fully grinding and mixing evenly, it is melted at high temperature to form a liquid melt;

[0037] The liquid melt is poured into a preheated mold, cooled and molded, and annealed to obtain a borosilicate vitrified substrate.

[0038] During specific implementation, the grinding particle size is 20 mesh to 40 mesh, and the preferred range is 30 mesh to 40 mesh; after such optimization, the material is mixed more uniformly due to the smaller particle size.

[0039] During specific implementation, the melting temperature can be 1200-1400°C, and the melting time can be 3-6h; preferably, the melting temperature is 1280°C, and the melting time is 3h , this is because the preferred post-melting temperature and time are short, which...

Embodiment 1

[0049] This embodiment provides a borosilicate vitrified substrate, which comprises the following components in terms of mass percent: SiO 2 55%, B 2 o 3 13%, Na 2 O 10%, BaO 2%, TiO 2 1%, Fe 2 o 3 1%, A1 2 o 3 9%, CaO 0%, Y 2 o 3 9%.

[0050] The preparation method of the above-mentioned borosilicate glass-cured substrate specifically comprises the following steps:

[0051] (1) select the raw material of borosilicate vitrification base material, by mass percentage, described raw material comprises following component: SiO 2 55%, B 2 o 3 13%, Na 2 O 10%, BaO 2%, TiO 2 1%, Fe 2 o 3 1%, A1 2 o 3 9%, CaO 0%, Y 2 o 3 9%;

[0052] (2) Put the raw materials into a mixer to fully grind and mix them; place them in a high-temperature furnace and melt them at 1300° C. for 3 hours to completely melt the batching materials into a liquid melt; the grinding particle size is 30 mesh;

[0053] (3) Pour the liquid melt into a mold preheated at 480°C, cool it in...

Embodiment 2

[0055] This embodiment provides a borosilicate vitrified substrate, which comprises the following components in terms of mass percent: SiO 2 53%, B 2 o 3 14%, Na 2 O 12%, BaO 4%, TiO 2 1%, Fe 2 o 3 1%, A1 2 o 3 8%, CaO 0%, Y 2 o 3 7%.

[0056] The preparation method of the above-mentioned borosilicate glass-cured substrate specifically comprises the following steps:

[0057] (1) select the raw material of borosilicate vitrification base material, by mass percentage, described raw material comprises following component: SiO 2 53%, B 2 o 3 14%, Na 2 O 12%, BaO 4%, TiO 2 1%, Fe 2 o 3 1%, A1 2 o 3 8%, CaO 0%, Y 2 o 3 7%;

[0058] (2) Put the raw materials into a mixer to fully grind and mix them; place them in a high-temperature furnace and melt them at 1280° C. for 3 hours to completely melt the batching materials into a liquid melt; the grinding particle size is 30 mesh;

[0059] (3) Pour the liquid melt into a mold preheated at 460°C, cool it in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com