Application of static mixer in nitrotoluene gas-phase catalytic hydrogenation process

A technology of static mixer and mononitrotoluene, which is applied in the application field of static mixer in the gas-phase catalytic hydrogenation process of mononitrotoluene, which can solve the problems of uneven reaction, increased production cost, and short catalyst life cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

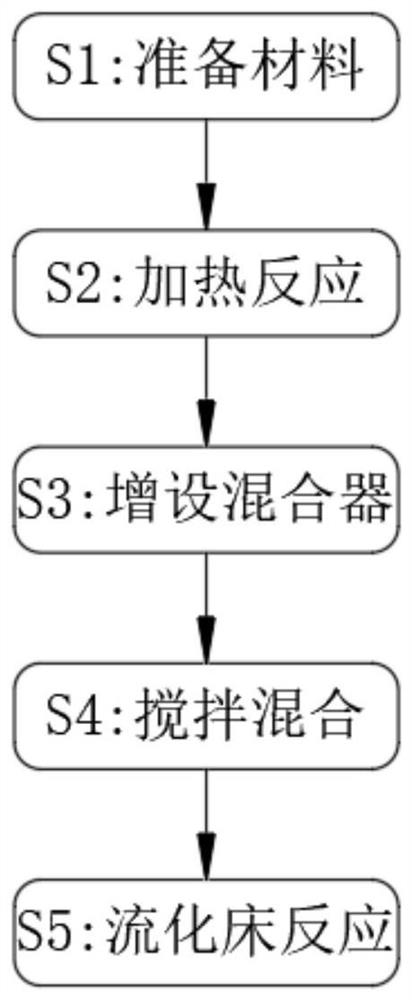

[0033] The present invention provides a technical solution: the application of a static mixer in the gas-phase catalytic hydrogenation process of mononitrotoluene, and the process steps include the following:

[0034] S1, preparation materials: prepare mononitrotoluene, hydrogen and a static mixer, and connect the mononitrotoluene connecting pipe and the hydrogen connecting pipe to one end of the static mixer through a flange;

[0035] S2, heating reaction: feed mononitrotoluene and hydrogen into the static mixer for mixed reaction, the heating device installed at the outer end of the static mixer controls the rapid heating of gas phase catalysis, and the temperature range is controlled at about 75°C-100°C;

[0036] S3, adding a mixer: the other end of the static mixer is connected with a custom mixer through a thread, and the additional custom mixer promotes the full mixing reaction of mononitrotoluene and hydrogen, and then controls the rapid heating at the same time through ...

example 2

[0040]The present invention provides a technical solution: the application of a static mixer in the gas-phase catalytic hydrogenation process of mononitrotoluene, and the process steps include the following:

[0041] S1, preparation materials: prepare mononitrotoluene, hydrogen and a static mixer, and connect the mononitrotoluene connecting pipe and the hydrogen connecting pipe to one end of the static mixer through a flange;

[0042] S2, heating reaction: feed mononitrotoluene and hydrogen into the static mixer for mixed reaction, the heating device installed at the outer end of the static mixer controls rapid heating of gas phase catalysis, and the temperature range is controlled at about 75°C-100°C;

[0043] S3, adding a mixer: the other end of the static mixer is connected with a custom mixer through a thread, and the additional custom mixer promotes the full mixing reaction of mononitrotoluene and hydrogen, and then controls the rapid heating at the same time through the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com