Production process of degradable sealant

A production process and technology of sealant, applied in the field of sealant, can solve the problems that the sealant cannot well meet the sealing effect and the difficulty of natural degradation, and achieve the effects of fast degradation rate, non-toxic stability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

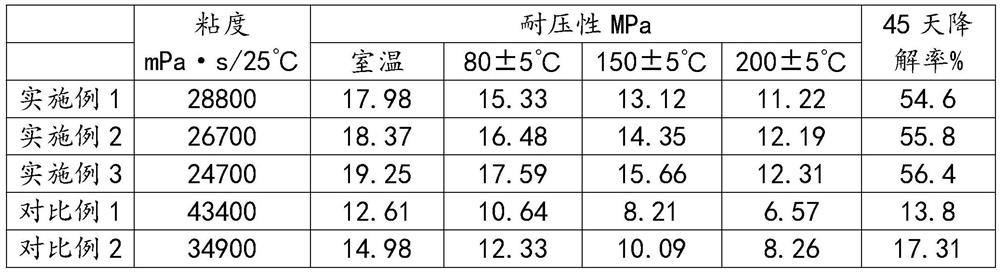

Examples

Embodiment 1

[0039] This embodiment is a production process of degradable sealant, comprising the following steps:

[0040] Step 1: Weigh 40 parts by weight of modified rubber, 4 parts of chlorinated polyethylene, 0.2 part of calcium stearate, 0.02 part of antioxidant, 2 parts of plasticizer, 0.1 part of photocatalyst, 3 parts of degradation material, acetic acid 15 parts of butyl esters and 12 parts of methylcyclohexane are set aside;

[0041] Step 2: masticating the modified rubber and chlorinated polyethylene to obtain the plasticizing material, then mixing the plasticizing material, calcium stearate, antioxidant, plasticizer, photocatalyst, and degradation material evenly, and cooling Chopped into granules to obtain the mixed material;

[0042] Step 3: Add the mixing material to the mixed solution of butyl acetate and methylcyclohexane, and disperse evenly under the condition of rotating speed of 500-800r / min to obtain the degradable sealant.

[0043] The antioxidant is antioxidant 1...

Embodiment 2

[0065] This embodiment is a production process of degradable sealant, comprising the following steps:

[0066] Step 1: Weigh 50 parts of modified rubber, 6 parts of chlorinated polyethylene, 0.3 part of calcium stearate, 0.03 part of antioxidant, 3 parts of plasticizer, 0.3 part of photocatalyst, 4 parts of degradation material, acetic acid 20 parts of butyl ester and 16 parts of methylcyclohexane, spare;

[0067] Step 2: masticating the modified rubber and chlorinated polyethylene to obtain the plasticizing material, then mixing the plasticizing material, calcium stearate, antioxidant, plasticizer, photocatalyst, and degradation material evenly, and cooling Chopped into granules to obtain the mixed material;

[0068] Step 3: Add the mixing material to the mixture of butyl acetate and methylcyclohexane, and disperse evenly under the condition of rotating speed of 650r / min to obtain the degradable sealant.

[0069] The antioxidant is antioxidant 1010; the plasticizer is epoxi...

Embodiment 3

[0091] This embodiment is a production process of degradable sealant, comprising the following steps:

[0092] Step 1: Weigh 60 parts of modified rubber, 8 parts of chlorinated polyethylene, 0.4 part of calcium stearate, 0.04 part of antioxidant, 5 parts of plasticizer, 0.5 part of photocatalyst, 5 parts of degradation material, acetic acid 25 parts of butyl esters and 20 parts of methylcyclohexane are set aside;

[0093] Step 2: masticating the modified rubber and chlorinated polyethylene to obtain the plasticizing material, then mixing the plasticizing material, calcium stearate, antioxidant, plasticizer, photocatalyst, and degradation material evenly, and cooling Chopped into granules to obtain the mixed material;

[0094] Step 3: Add the mixing material to the mixed solution of butyl acetate and methylcyclohexane, and disperse evenly under the condition of rotating speed of 800r / min to obtain the degradable sealant.

[0095] The antioxidant is antioxidant 1076; the plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com