650 MPa-grade steel for automobile wheel and preparation method of 650 MPa-grade steel

A technology for automobiles and wheels, which is applied in the field of 650MPa grade automobile wheel steel and its preparation, can solve the problems of affecting the surface quality of billets, difficult process control, and difficult control of microstructure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

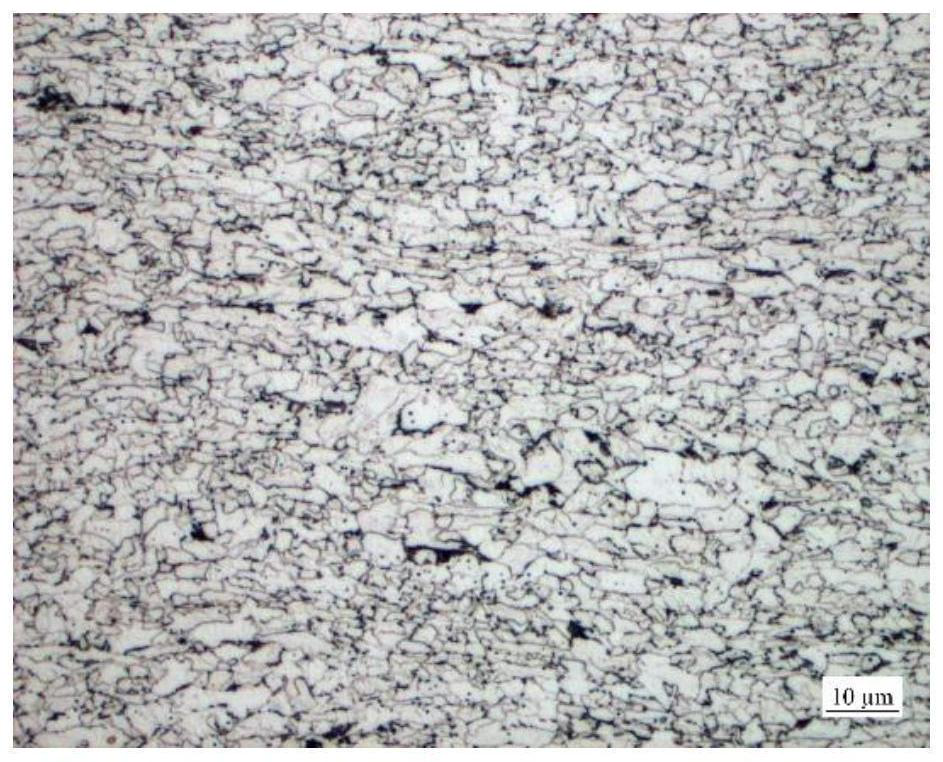

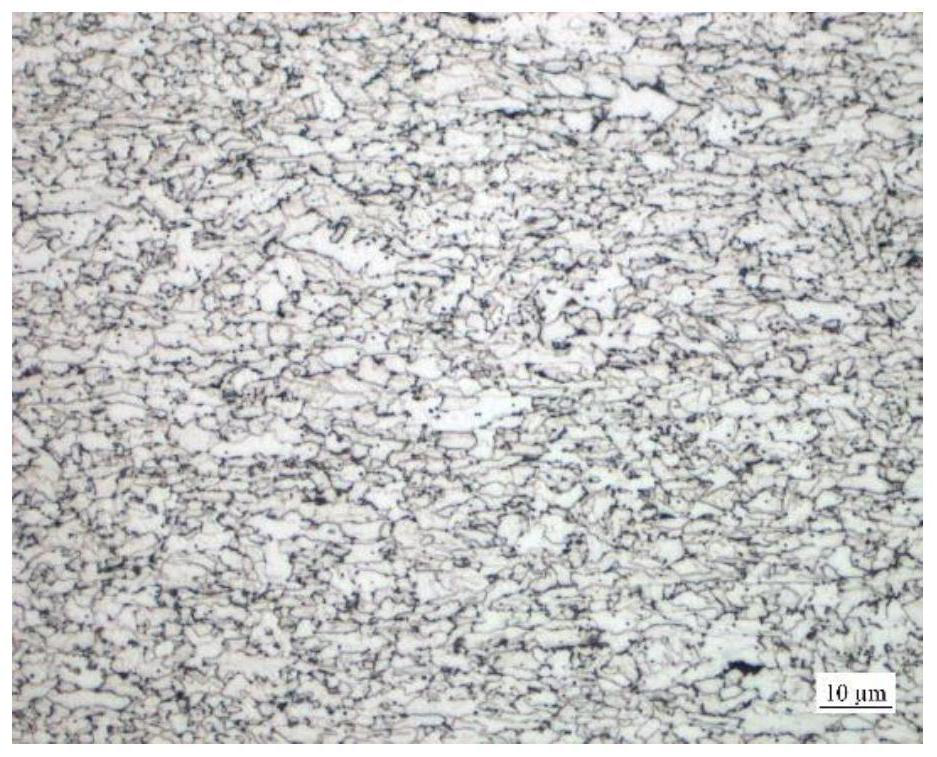

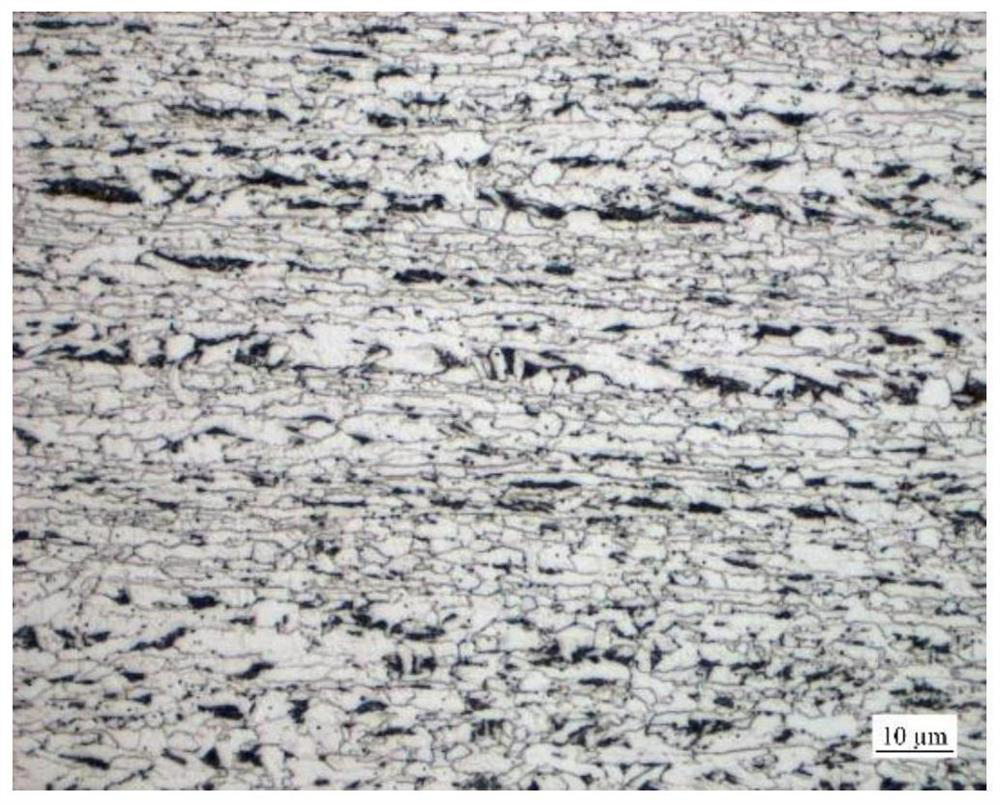

Image

Examples

preparation example Construction

[0037] The present invention also provides the preparation method of above-mentioned 650MPa level automobile wheel steel, comprises the following steps:

[0038] A) carrying out pre-desulfurization of molten steel smelted in a blast furnace;

[0039] B) performing converter smelting, LF refining and continuous casting on the molten iron obtained in step A) in sequence to obtain a slab;

[0040] C) Heating the slab and then side pressing it, then rolling it, and finally performing laminar flow cooling to obtain 650MPa grade steel for automobile wheels.

[0041] This application first elaborates the smelting method of 650MPa grade automobile wheel steel:

[0042] In the process of smelting, the molten iron is pre-desulfurized first, specifically: the molten iron obtained from blast furnace smelting is pre-desulfurized to control the S content and reduce the level of A-type inclusions, so as to avoid the formation of wheel steel caused by high inclusions. Cracking, S The conten...

Embodiment 1

[0055] (1) Pre-desulfurization of molten iron: pre-desulfurizing the molten iron obtained by blast furnace smelting, the S content is controlled at 0.003wt%;

[0056] (2) Converter smelting: put the above pre-desulfurized molten iron into the converter for smelting, the loaded molten iron weighs 180-250t, 300kg of aluminum and iron is used for deoxidation, manganese is used to mix manganese, and 800-1200kg of active lime is used for desulfurization;

[0057] (3) LF refining: carry out LF refining on the molten steel smelted in the above-mentioned converter, adopt white slag for desulfurization, control the S content to ≤0.005wt%, and desulfurize for 41 minutes;

[0058] (4) Continuous casting: transfer the above-mentioned LF refined molten steel into the tundish for casting, and then pass through the crystallizer to produce cast slabs, put into use dynamic light reduction, and the reduction is controlled to ≥ 3mm, and the secondary cooling water adopts weak cooling mode , the ...

Embodiment 2

[0062] (1) Pre-desulfurization of molten iron: pre-desulfurizing the molten iron obtained by blast furnace smelting, the S content is controlled at 0.003wt%;

[0063] (2) Converter smelting: put the above-mentioned pre-desulfurized molten iron into the converter for smelting, the weight of the charged molten iron is 180-250t, and 290kg of aluminum and iron are used for deoxidation, manganese is used to mix manganese, and 800-1200kg of active lime is used for desulfurization;

[0064] (3) LF refining: carry out LF refining on the above-mentioned molten steel smelted in the converter, adopt white slag to desulfurize, control the S content to ≤0.003wt%, and desulfurize for 36 minutes;

[0065] (4) Continuous casting: transfer the above-mentioned LF refined molten steel into the tundish for casting, and then pass through the crystallizer to produce cast slabs, put into use dynamic light reduction, and the reduction is controlled to ≥ 3mm, and the secondary cooling water adopts weak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com