A high-order aspheric detection method based on adaptive optics wavefront correction

A high-order aspheric and adaptive optics technology, which is applied in the direction of using optical devices, measuring devices, instruments, etc., to achieve the effect of taking into account the versatility and detection accuracy of the system, improving the measurement range and flexibility, and improving the dynamic measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

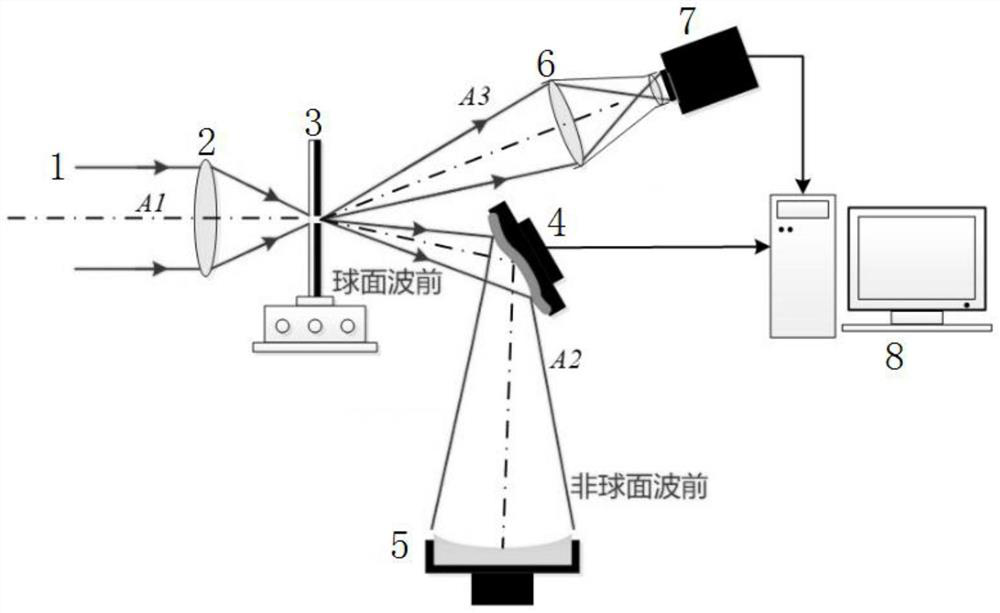

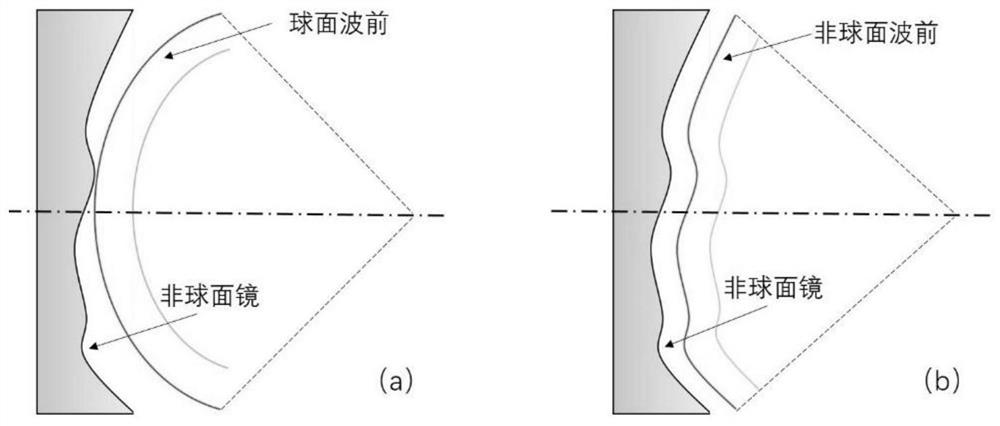

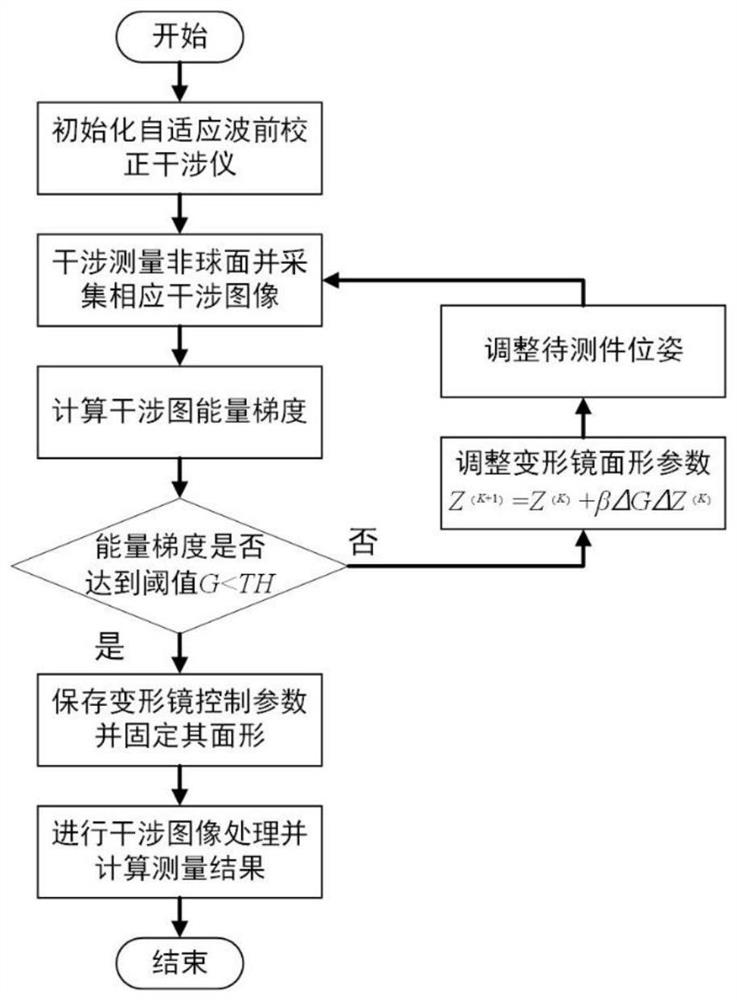

[0052] The invention provides a high-order aspheric surface detection method and system based on adaptive optics wavefront correction. By changing the shape of the deformed mirror to correct the spherical wavefront of the interferometer, it is converted into an aspheric surface approximate to the shape of the aspheric surface to be measured. Near-zero measurement of the spherical wavefront; the two-step Zernike mode random parallel gradient descent algorithm is used to establish the relationship model between the adjustment amount and the measurement amount, which reduces the fringe density of the interferogram during measurement and improves the detection accuracy; finally, the reverse optimization method of ray tracing is used Eliminate the backhaul error in the measurement amount and obtain the final measurement result, which can make up for the shortcomings of the traditional interferometer, such as the small dynamic range of measurement, the large cumulative error of sub-ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com