Thermal response testing method for rock-soil thermal conductivity distribution

A technology of thermal response testing and thermal conductivity, applied in geothermal energy power generation, special data processing applications, instruments, etc., can solve the large deviation of test results, the increase of thermal conductivity distribution test error, and the increase of fluid average temperature estimation error and other issues to achieve the effect of improving test efficiency and reducing test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

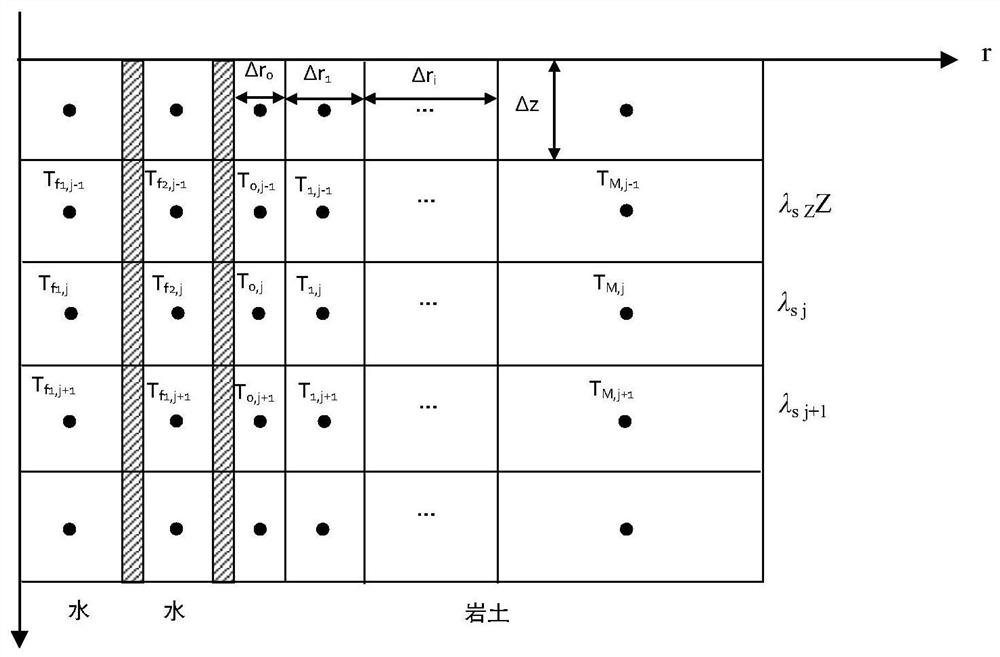

[0020] Taking the casing and buried pipe heat exchanger as an example, the specific implementation method of the present invention is as follows: firstly, analyze the heat transfer of the fluid in the borehole, the pipeline, the backfill layer and the rock and soil in the heat exchanger, wherein the heat transfer of the fluid in the pipe is one-dimensional Unsteady state, the energy balance equation of the fluid in the inner tube can be expressed as:

[0021]

[0022] where T f1 is the inner tube fluid temperature, dQ 12 / dz is the heat transfer between the inner and outer tubes. The first item on the right side of the equation represents the unsteady heat transfer of the fluid, and the second item represents the convective heat transfer of the fluid along the depth direction. The energy balance equation in the outer tube is:

[0023]

[0024] where T f2 is the fluid temperature of the outer pipe, and dQ / dz represents the heat exchange between the heat exchanger fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com