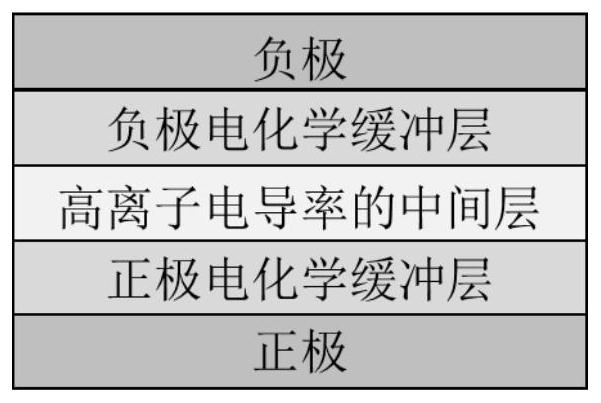

Composite electrolyte material with electrochemical buffer layer, preparation method thereof and lithium metal battery

A composite electrolyte and electrochemical technology, applied in the field of lithium-ion batteries, can solve problems such as difficult to meet energy density cycle performance, poor interface contact, and chemical instability of lithium metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0152] The present invention also provides a method for preparing a composite electrolyte material with an electrochemical buffer layer described in the above technical solution, comprising the following steps:

[0153] a) mixing polymer A, lithium salt and solvent to obtain positive electrode electrochemical buffer layer slurry;

[0154] mixing polymer B, lithium salt and solvent to obtain negative electrode electrochemical buffer layer slurry;

[0155] Mixing polymer C, ceramic electrolyte, lithium salt and solvent to obtain composite electrolyte interlayer slurry;

[0156] b) The positive electrode electrochemical buffer layer slurry, the composite electrolyte intermediate layer slurry and the negative electrode electrochemical buffer layer slurry are sequentially stacked and dried to obtain a composite electrolyte material with an electrochemical buffer layer.

[0157] The types and dosages of the polymer A, polymer B, polymer C, lithium salt and ceramic electrolyte are c...

Embodiment 1

[0170] 1.1 Sample preparation

[0171] S1, 70 parts of polyvinylidene fluoride, 30 parts of LiN(CF 3 SO 2 ) 2 1000 parts of N,N-dimethylformamide were mixed at 50° C. for 6 hours by mechanical stirring to obtain a positive electrode electrochemical buffer layer slurry.

[0172] S2, 80 parts of polyethylene oxide, 20 parts of LiN(CF 3 SO 2 ) 2 1000 parts of acetonitrile were mixed by mechanical stirring at room temperature for 6 hours to obtain the negative electrode electrochemical buffer layer slurry.

[0173] S3. At room temperature, the ceramic electrolyte Li 10 GeP 2 S 12 Grind to particles with an average particle size of 320 nm. Under the protection of argon atmosphere, 30 parts of polyvinylidene fluoride, 15 parts of LiN(CF 3 SO 2 ) 2 , 55 Li 10 GeP 2 S 12 The nanoparticles and 400 parts of N,N-dimethylformamide were mixed at room temperature for 6 hours by a high-energy ball mill to obtain a composite electrolyte interlayer slurry.

[0174] S4. Scrape-c...

Embodiment 2

[0184] 1.1 Sample preparation

[0185] S1, 80 parts of polymethacrylate, 20 parts of LiN(FSO 2 ) 21000 parts of N,N-dimethylformamide were mixed at 50° C. for 6 hours by high-energy ball milling to obtain a positive electrode electrochemical buffer layer slurry.

[0186] S2, 70 parts of polyethylene oxide, 30 parts of LiN(CF 3 SO 2 ) 2 1000 parts of acetonitrile were mixed at room temperature for 6 hours by high-energy ball milling to obtain the negative electrode electrochemical buffer layer slurry.

[0187] S3. At room temperature, the ceramic electrolyte Li 7 La 3 Zr 2 o 12 Grind to particles with an average particle size of 400 nm. Under the protection of argon atmosphere, 20 parts of polyethylene oxide, 5 parts of LiN(FSO 2 ) 2 , 75 Li 7 La 3 Zr 2 o 12 The nanoparticles and 400 parts of acetonitrile were mixed for 6 hours at room temperature by a roller mill to obtain a composite electrolyte interlayer slurry.

[0188] S4. Squeeze-coat the positive electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com