Distillation system used for preparing furfural

A distillation system and furfural technology, applied in distillation separation, distillation adjustment/control, organic chemistry, etc., can solve the problems of not having the support and buffer function of the collection frame, not having the ability to promote gas flow, and inconvenient to remove the collection frame, etc. The effect of convenient installation, convenient disassembly and convenient limit function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

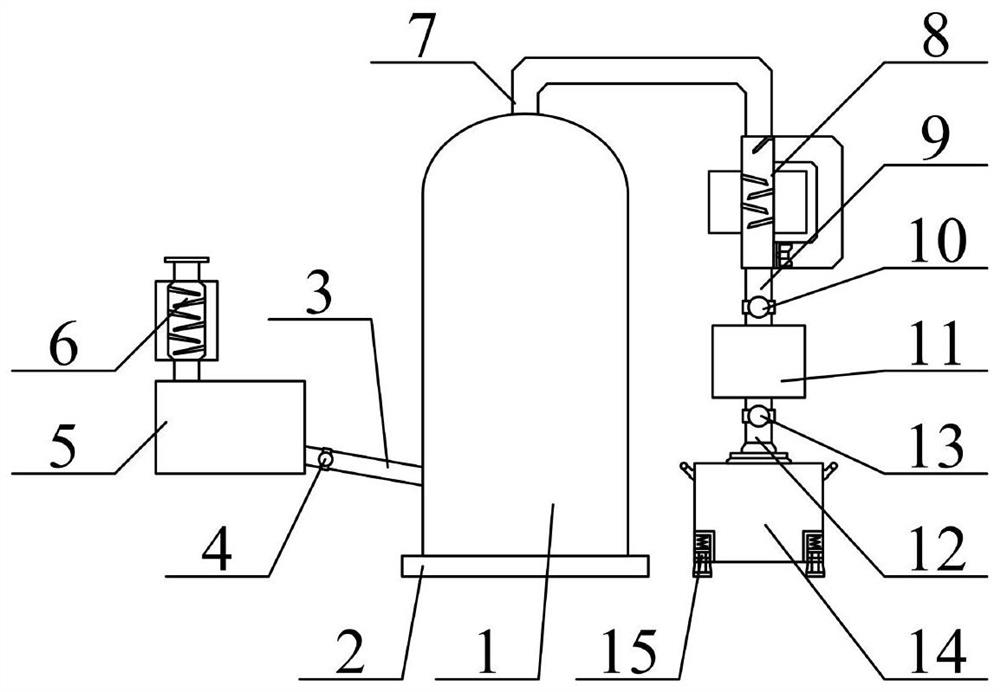

[0040] as attached figure 1 And attached Figure 5 shown

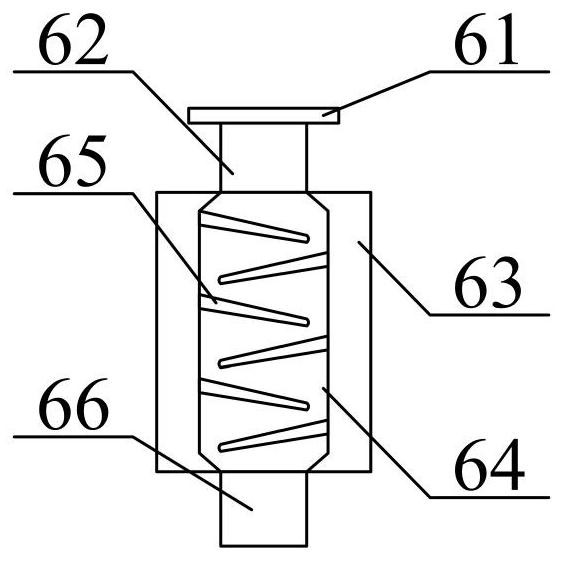

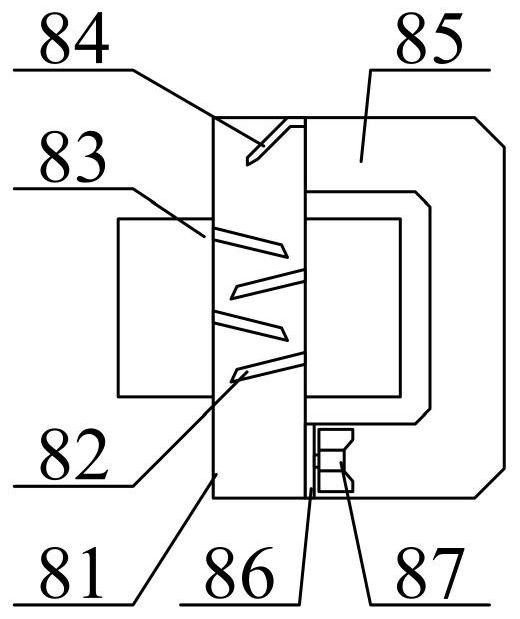

[0041]The present invention provides a distillation system for producing furfural, comprising a distillation tower 1, a bottom fixed frame 2, an inlet pipe 3, an inlet valve 4, a stock solution tank 5, an inlet condensation frame structure 6, an air outlet pipe 7, a circulation condensation frame structure 8, The outlet pipe 9, the outlet valve 10, the furfural metering tank 11, the discharge pipe 12, and the discharge valve 13 are used to dismantle the receiving frame structure 14 and the buffer support frame structure 15, and the bottom fixing frame 2 bolts are installed on the bottom of the distillation tower 1 The introduction pipe 3 is plugged in the lower left side of the distillation tower 1; the introduction valve 4 is threaded on the left side of the introduction pipe 3; the stock solution tank 5 is welded on the left side of the introduction pipe 3; The introduction condensing rack structure 6 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com