Dust removal and purification device for dust-containing waste gas

A purification device and exhaust gas technology, applied in combined devices, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as affecting gas components, huge capital investment, and unfavorable overall improvement of the global climate and environment, so as to improve separation and adsorption effect, enhancing the effect of centrifugation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

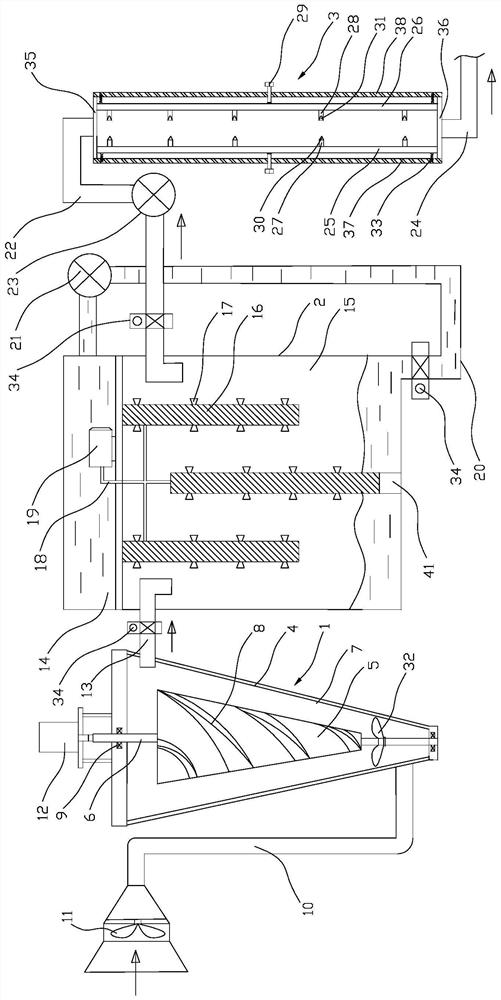

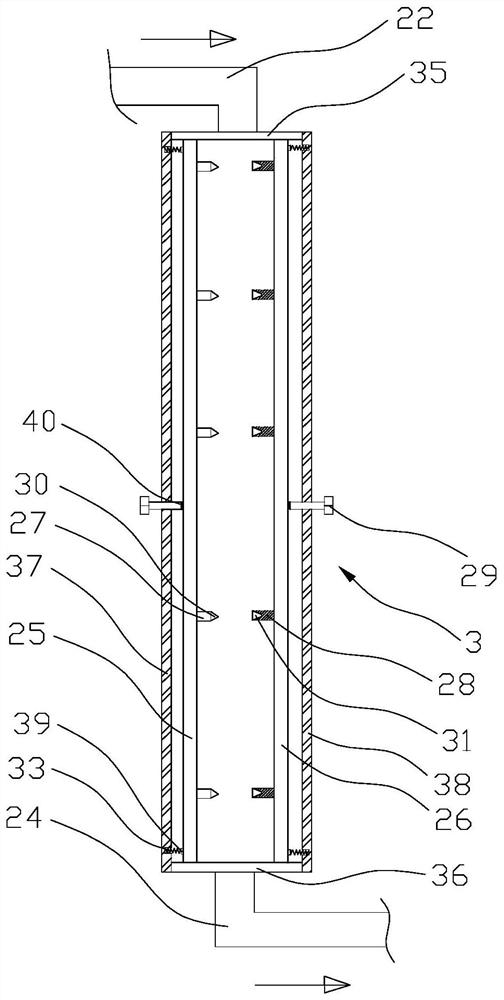

[0022] see figure 1 , a kind of dust-reducing and purifying device for dusty waste gas, comprising a cyclone dust removal box 1, an atomization box 2 and a plasma discharge chamber 3, the cyclone dust removal box 1 includes a conical outer cylinder 4, a conical wind guide hood 5, and a conical outer cylinder 4 is made up of two hinged semi-conical tubes. There is a gap between the conical outer cylinder 4 and the conical air guide 5 for the circulation of exhaust gas. The conical air guide 5 is installed on the rotating shaft 6 coaxial with it, and both ends of the rotating shaft 6 are rotated by bearings 9 Installed on the top and the bottom of the conical outer cylinder 4, fan blades 32 are installed on the bottom of the rotating shaft 6, the wind direction of the fan blades 32 is set upwards, and the upper end of the rotating shaft 6 is connected with a motor 12 in transmission, the conical outer cylinder 4 The inner wall is pasted with an oil film layer 7. When the oil fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com