Method for forming special-shaped pipe fitting used in field of communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

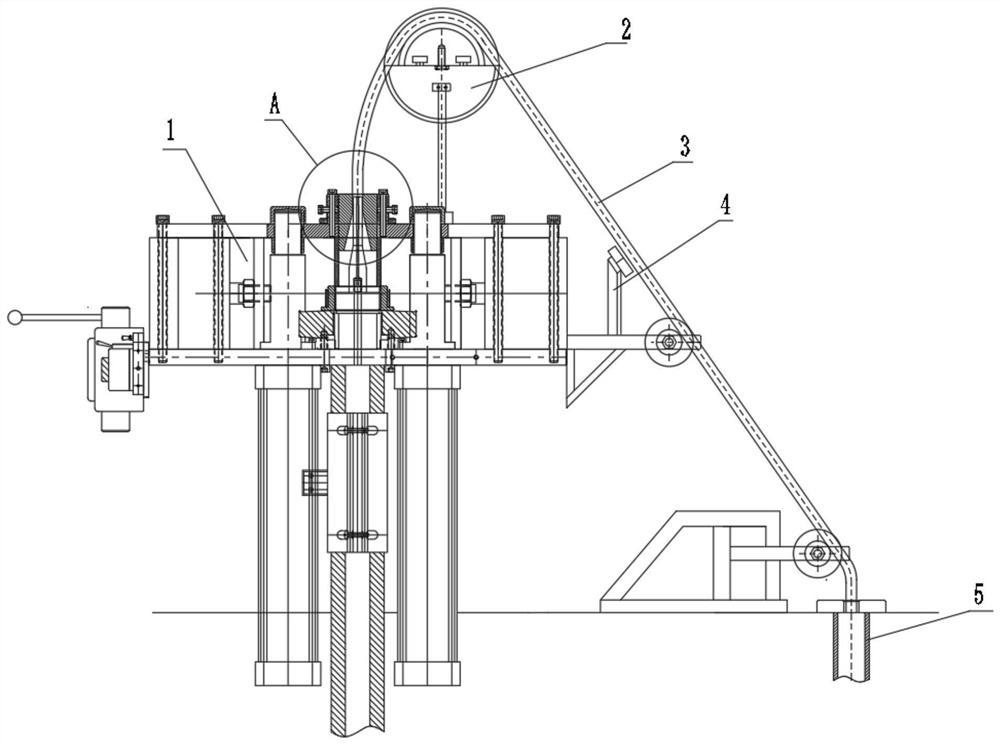

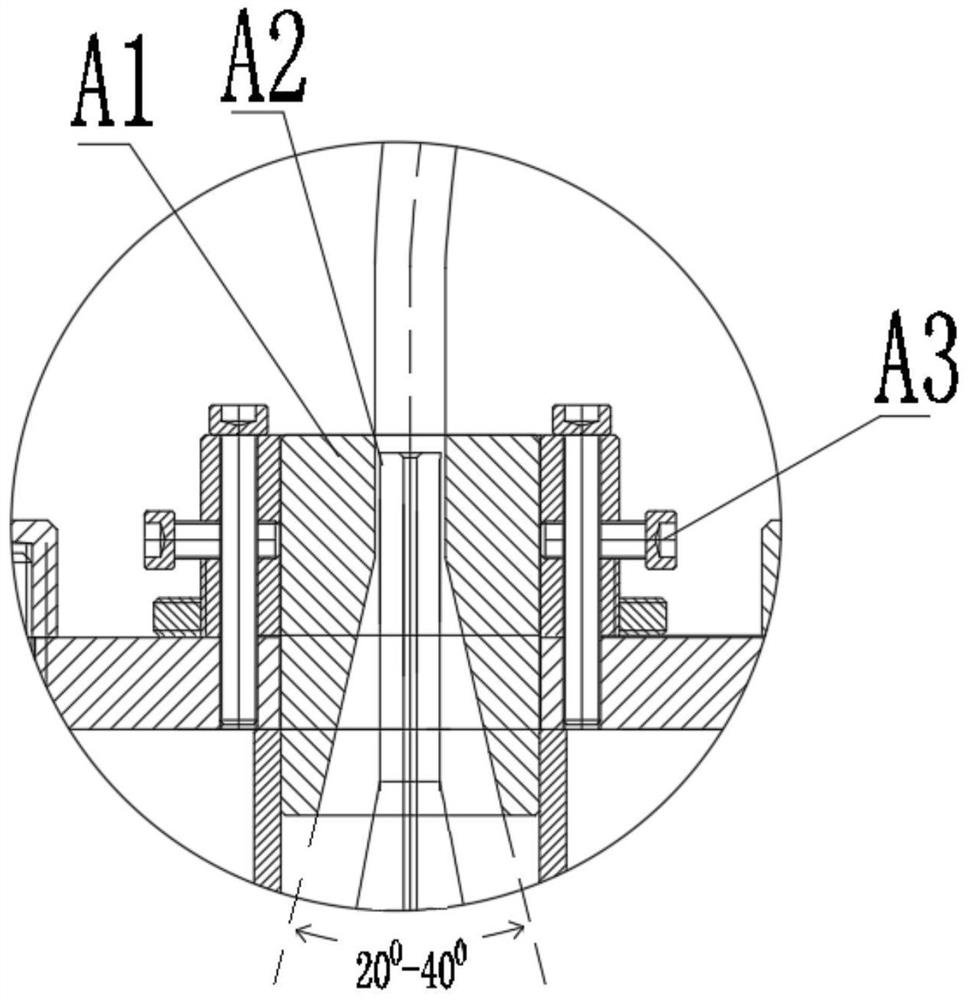

Image

Examples

Embodiment 1

[0034] A method for forming special-shaped pipe fittings used in the communication field, comprising the following steps:

[0035] (1) Clean the screen, put the empty special bucket on the outlet of the vibrating screen, open the vibrating screen, pour PTFE dispersion resin, and separate the large impurities and agglomerates.

[0036] (2) The electronic scale weighs an empty special barrel, peels it, pours PTFE dispersion resin with a weight ratio of 50% into the barrel, and takes out a specified weight of extrusion aid and anti-extrusion deformation powder from a measuring cup. The weight ratio of extrusion aid is 40%, the weight ratio of the anti-extrusion deformation powder is 10%, pour it into the barrel that has been added to the main resin, tighten the lid, fix the mixed barrel on the mixer, turn on the mixer to mix, and get the mixed material. Wherein the extrusion aid includes petroleum ether, aviation kerosene or isoparaffin, preferably isoparaffin. The anti-extrusi...

Embodiment 2

[0044] A method for forming special-shaped pipe fittings used in the communication field, comprising the following steps:

[0045] (1) Clean the screen, put the empty special bucket on the outlet of the vibrating screen, open the vibrating screen, pour PTFE dispersion resin, and separate the large impurities and agglomerates.

[0046] (2) The electronic scale weighs the empty special barrel, peels it, pours PTFE dispersion resin with a weight ratio of 40% into the barrel, and takes out the specified weight of extrusion aid and anti-extrusion deformation powder from the measuring cup. The weight ratio of extrusion aid is 20%, the weight ratio of the anti-extrusion deformation powder is 40%, pour it into the barrel that has been added to the main resin, tighten the lid, fix the mixed barrel on the mixer, turn on the mixer to mix, and get the mixed material. The extrusion aid includes petroleum ether, aviation kerosene or isoparaffin. The anti-extrusion deformation powder inclu...

Embodiment 3

[0054] A method for forming special-shaped pipe fittings used in the communication field, comprising the following steps:

[0055] (1) Clean the screen, put the empty special bucket on the outlet of the vibrating screen, open the vibrating screen, pour PTFE dispersion resin, and separate the large impurities and agglomerates.

[0056] (2) The electronic scale weighs an empty special barrel, peels it, pours PTFE dispersion resin with a weight ratio of 50% into the barrel, and takes out a specified weight of extrusion aid and anti-extrusion deformation powder from a measuring cup. The weight ratio of extrusion aid is 30%, the weight ratio of the anti-extrusion deformation powder is 20%, pour it into the barrel that has been added to the main resin, tighten the lid, fix the mixed barrel on the mixer, turn on the mixer to mix, and get the mixed material. The extrusion aid includes petroleum ether, aviation kerosene or isoparaffin. The anti-extrusion deformation powder includes c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com