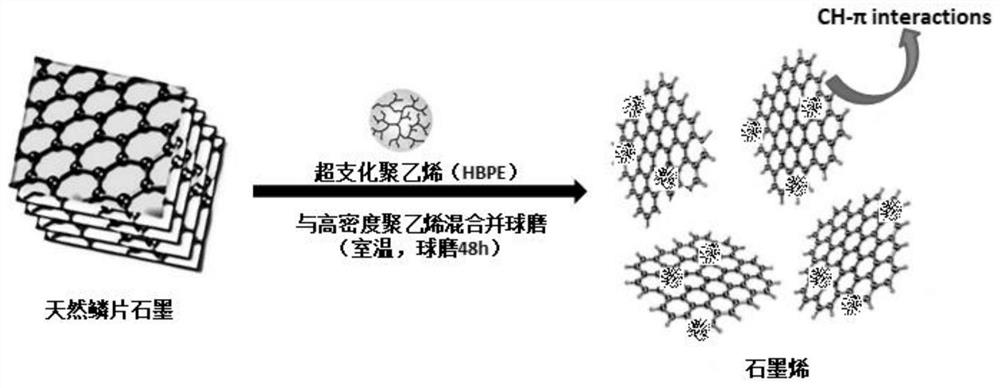

A method for preparing graphene by using hyperbranched polyethylene as an auxiliary ball milling method

A technology of hyperbranched polyethylene and ball milling, which is applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of low electrical conductivity and limit the application of graphene, and achieve simple methods, easy operation, and mild preparation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 0

[0067] Embodiment 0: prepare hyperbranched polyethylene (HBPE)

[0068] In this embodiment, hyperbranched polyethylene can be obtained by using Pd-diimine catalyst to catalyze ethylene, and obtain it by a one-step "chain removal" copolymerization mechanism. The specific preparation process includes the following steps:

[0069] Under the protection of nitrogen, add ethylene gas into the reaction vessel and ensure that there is no oxygen and water in the instrument. At the same time, ensure that the ethylene gas fills the entire reaction vessel. The solvent is anhydrous solvent, and the temperature is controlled at 25 ° C. Pd-diimine catalyst in anhydrous grade solvent, stirred and reacted for 24 hours at a temperature of 25°C and an ethylene pressure of 0.1 MPa. After the polymerization was completed, the resulting product was poured into acidified methanol to terminate the polymerization. The obtained polymerization reaction mixture was separated and purified. Obtain hyperbra...

Embodiment 1

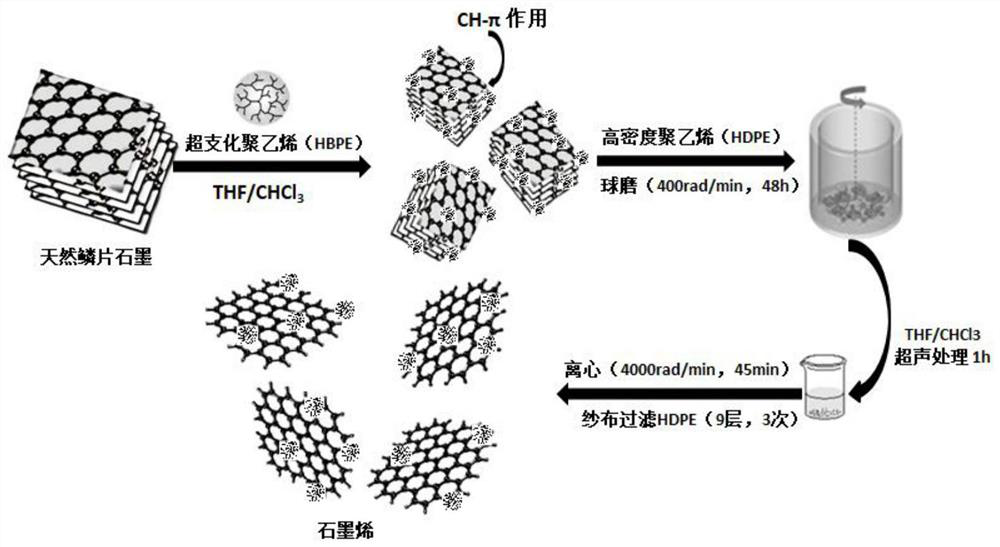

[0075] Embodiment 1, Comparative Examples 1 and 2

[0076] 1. Preparation of samples

[0077] (1) embodiment 1: provide a kind of method that prepares graphene with hyperbranched polyethylene as auxiliary ball milling method, it prepares according to the following steps:

[0078] Step 1: Weigh 5g of natural graphite at normal temperature (the manufacturer is SigmaAldrich Company of the United States, the specification is 99.5%, and other examples and comparisons such as no special instructions also use this natural graphite).

[0079] Step 2: Weigh 0.416g of hyperbranched polyethylene and dissolve it in 15ml of chloroform.

[0080] Step 3: mix the HBPE solution and natural graphite, put them in a beaker, and add 35ml of chloroform to obtain a mixed solution of natural graphite and HBPE.

[0081] Step 4: Stir the mixture of natural graphite and HBPE, the stirring speed is 300rad / min, and the stirring time is 30min.

[0082] Step 5: Use a blower to remove the solvent in the m...

Embodiment 1、 comparative example 6、 comparative example 7

[0126] 1. Preparation of samples

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com