Continuous manufacturing method for electrode material

A manufacturing method and electrode material technology, applied in electrode manufacturing, battery electrodes, electrode heat treatment, etc., can solve the problems of rotary furnace blockage, hinder uniform heating, and inability to collect electrode materials, etc., and achieve the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

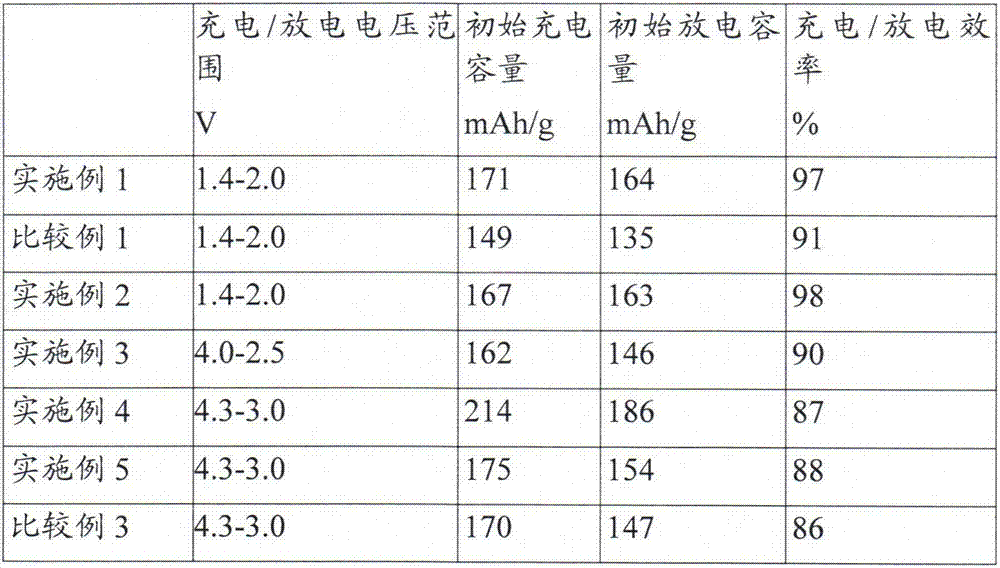

Examples

Embodiment 1

[0075] The mixture (solid concentration: 41% by weight, Li / Ti molar ratio: 0.82) was obtained by adding 29.1% by weight of anatase titanium dioxide particles [TiO 2 : Molecular weight 79.8658] (Sakai Chemical Industry Co., Ltd., SA-1, average primary particle size: 0.15μm, specific surface area: 9.7m 2 / g), 11.0% by weight lithium carbonate particles {Li 2 CO 3 (Molecular weight: 73.8909) (Kennametal Inc., 60M, average primary particle size: 5.3μm, specific surface area: 1.4m 2 / g)}, 58.1% by weight of ion-exchanged water, and 1.8% by weight of ethanol were mixed and prepared. The mixture was dried and calcined using a rotating cylinder with an inclination angle of 5° and a rotation rate of 30 rpm under an air flow of 15 L / min from the output side (furnace body length: 5 m, furnace tube diameter: 20 cm, impeller: from center to Length of leaf tip: 9 cm, 10 leaves). The heating temperature of the rotating cylinder was 700° C. at the input side, 850° C. at the center, and 85...

Embodiment 2

[0079] A lithium-titanium composite oxide compounded with fine carbon fibers was prepared according to the following procedure using a rotary cylinder heater as described in Example 1 and using fine carbon fiber agglomerates, titanium dioxide particles, and lithium hydroxide.

[0080] (1) Preparation of fine carbon fiber dispersion

[0081] 5 parts by weight of fine carbon fiber agglomerates (Ube Industries, Ltd., AMC, specific surface area: 230m 2 / g, average external diameter: 11 nm, average internal diameter: 6 nm, length: 0.5 μm to 10 μm) added to an aqueous solution of 1 weight part of carboxymethylcellulose (Daicel FineChem Ltd., CMC Daicel1110) in 94 parts by weight of ion-exchanged water After mixing, the agglomerates were opened for 40 min using an ultrasonic generator (Nippon Seiki CO., Ltd, ultrasonic homogenizer MODEL US-600T) to disperse the agglomerates to obtain a carbon fiber containing 5% by weight of fine carbon fibers. Fine carbon fiber dispersion.

[0082...

Embodiment 3

[0086] A lithium iron phosphate composite compounded with fine carbon fibers was prepared as follows using a rotating cylinder heater as used in Example 1 and fine carbon fiber agglomerates, magnetite particles, lithium carbonate and lithium phosphate.

[0087] By mixing 21.4% by weight phosphoric acid (H 3 PO 4 Molecular weight: 98.00) (Nippon Chemical Industrial Co., Ltd., purity: 85% by weight), 6.86% by weight of lithium carbonate as used in Example 1, and 34.4% by weight of ion-exchanged water were mixed to obtain lithium dihydrogen phosphate aqueous solution. To this solution was added 14.3% by weight magnetite particles (Fe 3 o 4 Molecular weight: 231.533) (Titan Kogyo Ltd., BL-100, specific surface area: 5.5m 2 / g) and 23.0% by weight of the fine carbon fiber dispersion prepared in Example 2 (1) (fine carbon fiber content is 5% by weight), and then the mixture is mixed under stirring to obtain a mixture (solid content: 22.3 % by weight, Li / Fe molar ratio: 1.00, Li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com