Combustor for lower combustion chamber of annular sleeve kiln and flameless combustion method

A technology of annular sleeve and combustion chamber, which is applied in the direction of combustion method, gas fuel burner, burner, etc., to achieve the effects of inhibiting the formation of nitrogen oxides, improving the thermal condition of the furnace, and reducing the formation of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention will be further described and explained below with reference to the accompanying drawings.

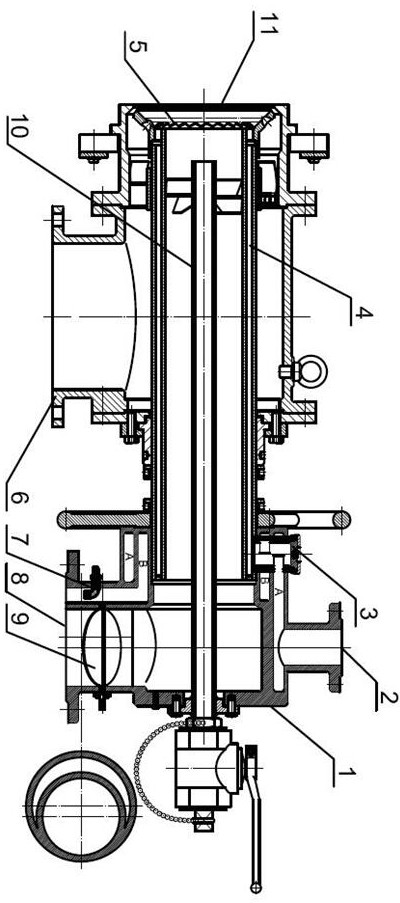

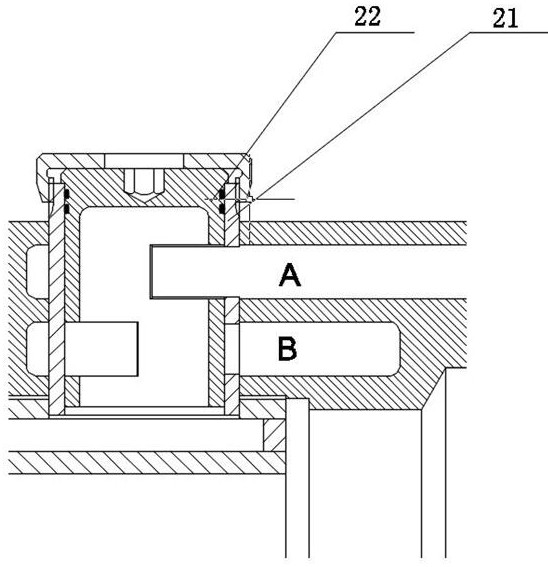

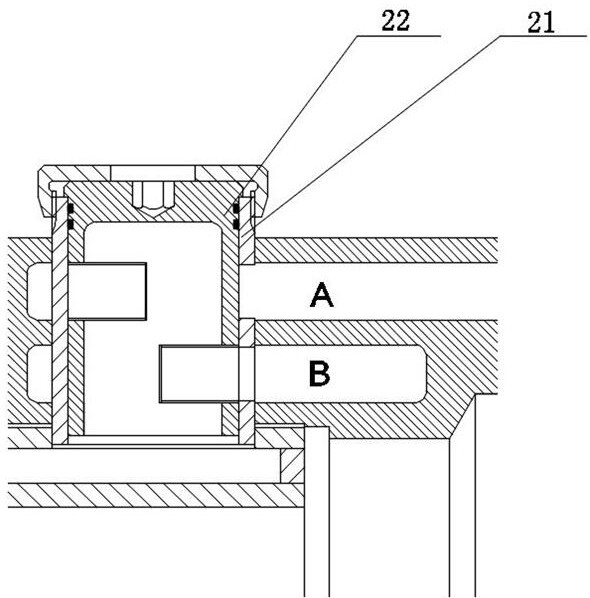

[0038]The present invention discloses a combustor and flameless combustion method for a combustion chamber under annular sleeve kiln. In the present embodiment,figure 1 As shown, a burner for the combustion chamber under the ring sleeve kiln includes a gas joint 1, a gas nozzle 4, an air joint 6, a central tube 10, and a burner spout 11, and a central tube 10 outer peripheral set of gas nozzle 4, the center tube 10 is provided with the gas joint 1, and the other end is provided with the burner nozzle 11, and the gas joint 1 and the burner nozzle 11 communicate through the gas nozzle 4, the intake end of the gas nozzle 4 communicates with the gas joint 1, and the depth communication The burner spray port 11; the central tube 10 is provided with an air joint 6 on one side of the burner spray port 11, and the gas nozzle 4 is a sleeve structure composed of two coaxial ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com