Inside-wind tunnel water tank push plate type wave generation system and wave generation method

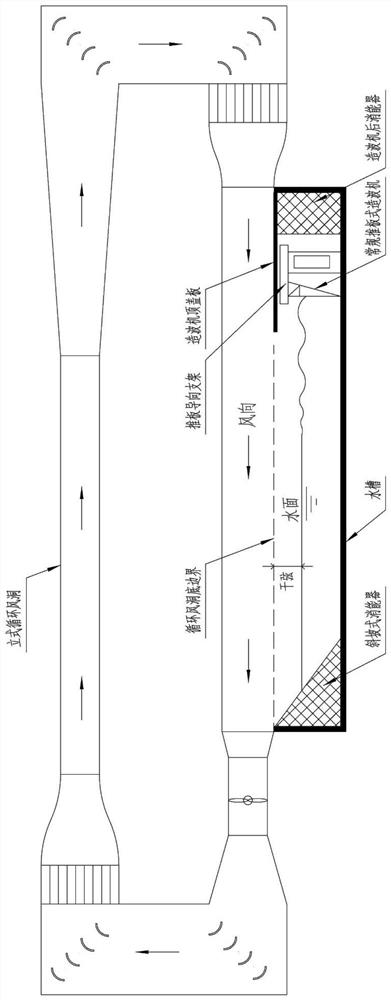

A technology of inner water tank and push plate, which is applied in measurement devices, instruments, aerodynamic tests, etc., can solve the problems of immersion motor, high input cost, large distance, etc., achieve small wave accuracy error, reduce input cost, dry string The effect of distance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

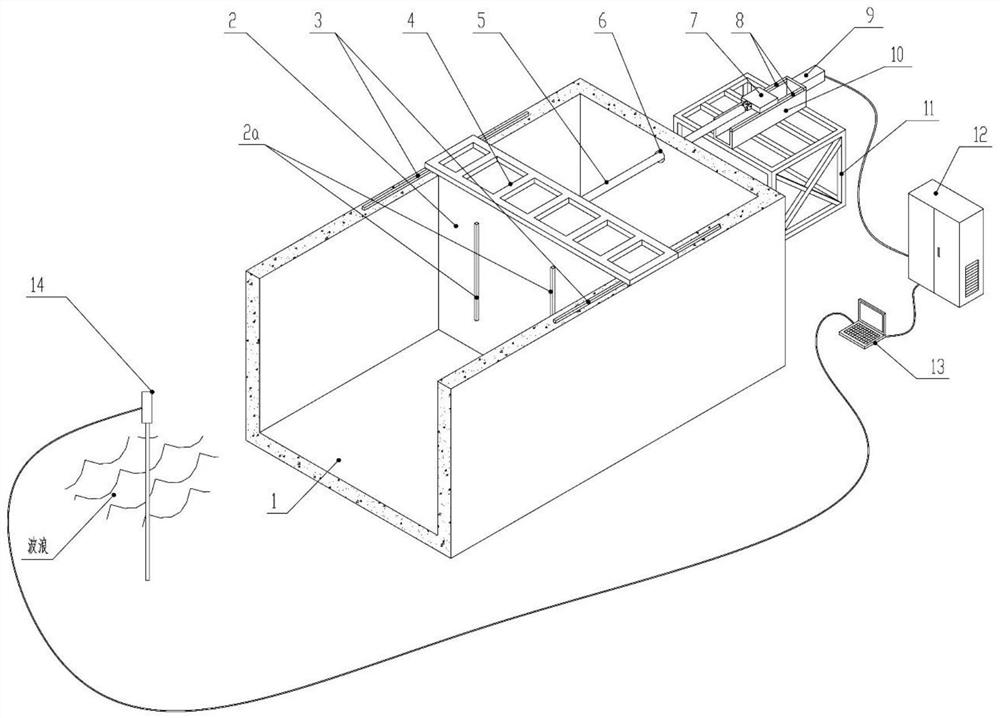

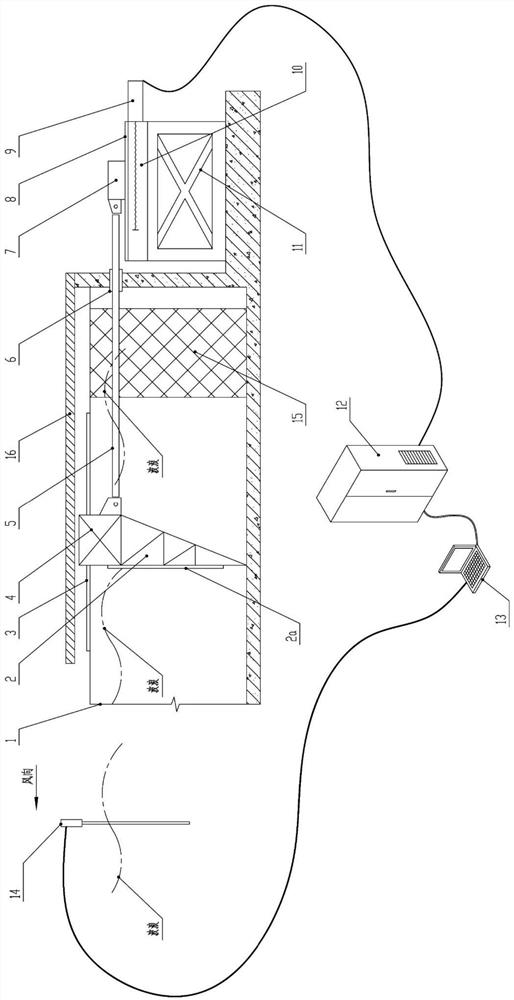

[0050] This embodiment provides a water tank push plate type wave-making system in a wind tunnel, including a wave machine installation section 1, a push plate 2, a first guide pair 3, a main sliding table beam 4, a push rod shaft 5, and a wall-penetrating waterproof bushing 6. The second sliding table 7, the second guide pair 8, the motor 9, the unit body 10, the frame 11, the servo control cabinet 12, the computer 13, the wave height sensor 14 in the test area;

[0051] Such as figure 2 and image 3 As shown, the first guide pair 3 is installed on the two side walls of the installation section 1 of the wave maker. The push plate 2 is located in the water tank and is fixedly connected with the main slide beam 4. The two ends of the main sliding table beam 4 are slidingly connected with the first guide pair 3 respectively, so that the rigid body composed of the main sliding table beam 4 and the push plate 2 can slide on the first guiding pair 3 . The main slide beam 4, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com