Anti-seepage and anti-cracking concrete and preparation method thereof

A concrete and anti-cracking technology, applied in the field of concrete, can solve the problems of performance degradation, combination of compactness and external cracking, and affecting the impermeability of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

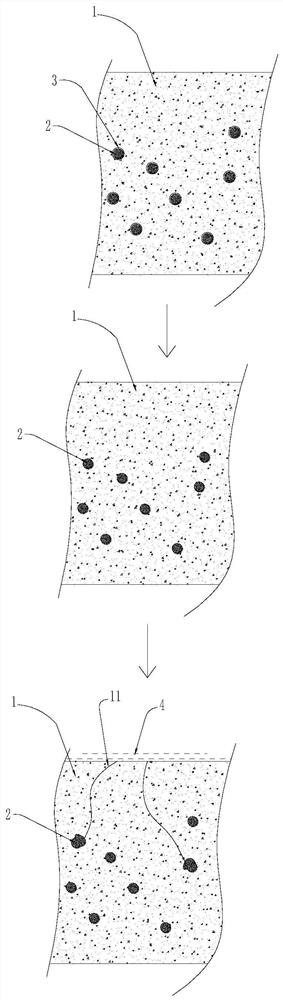

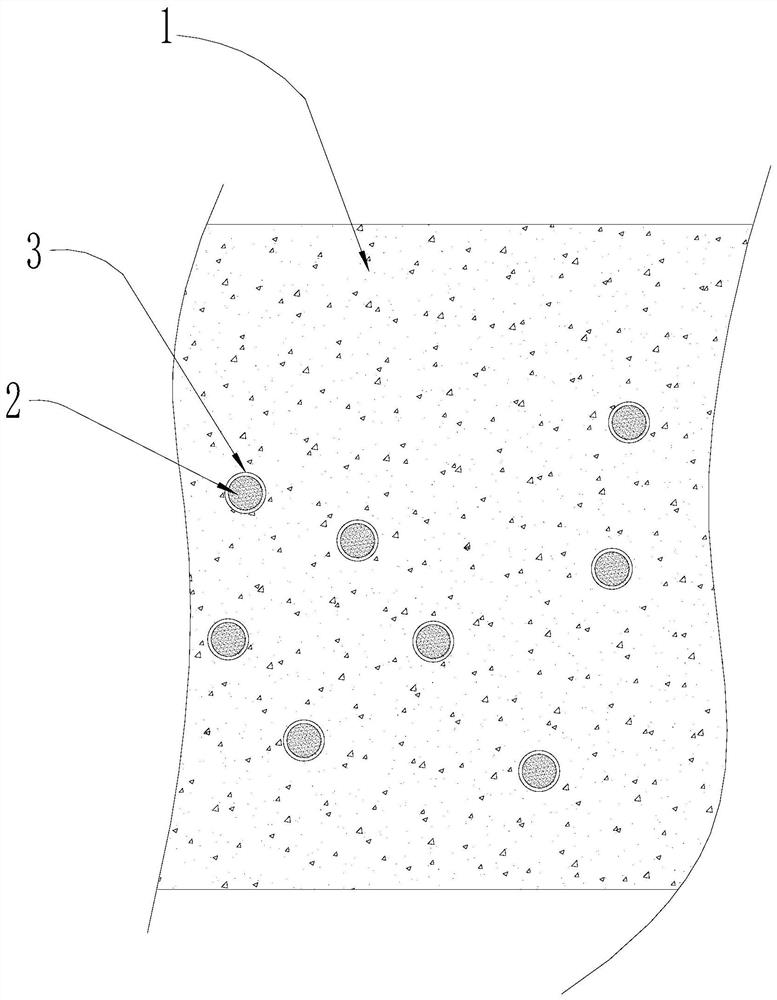

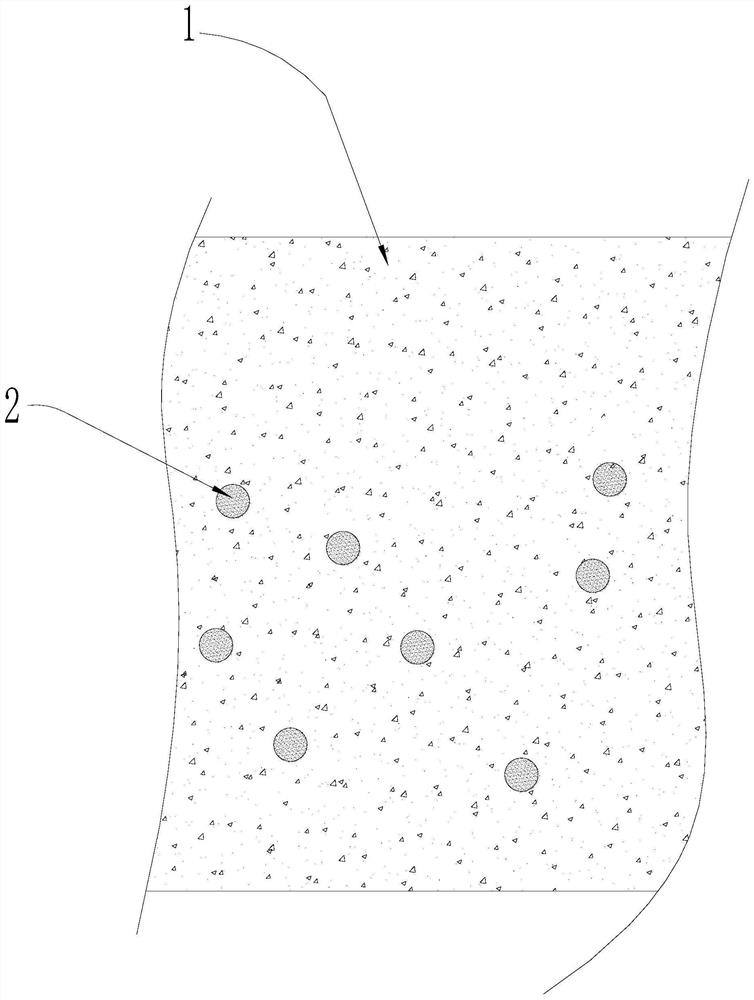

[0059] Based on the composition scheme of above-mentioned concrete, the present invention also provides a kind of anti-seepage, anti-cracking concrete preparation method, it uses above-mentioned anti-seepage, anti-cracking concrete, and this preparation method comprises the following steps:

[0060] (1) Pipette cement, sand, aggregate, fly ash, metakaolin, reinforcing fiber, water-absorbing elastomer, water reducing agent and water according to the preset metering ratio;

[0061] (2) Add 1 / 3 of water to the mixing equipment, then add 1 / 3 of the water reducer for mixing, then pour sand for pre-mixing, make the sand wet, and form material A;

[0062] (3) Pour the aggregate and reinforcing fiber into the mixing equipment and mix with material A evenly to obtain material B;

[0063] (4) After premixing fly ash, cement, metakaolin and water-absorbing elastomer, pour them into the mixing equipment and mix them evenly with material B. During the mixing process, the temperature of the...

Embodiment 1

[0068] A kind of anti-seepage, anti-cracking concrete, its raw material comprises following components:

[0069]

[0070] Wherein, the reinforcing fibers are polypropylene plastic fibers, which are formed by mixing polypropylene fibers with a length of 3.5 to 5 mm and a length of 7 to 8 mm in a ratio of 2:1; the particle size of the sand is 0.25 ~0.5mm, the aggregate is mixed with coarse aggregate with a particle size of 2.36~9.5mm and fine aggregate with a particle size of 0.15~2.36mm according to the ratio of 1:2; the pulverized coal The ash is obtained by grinding by-products of coal combustion in thermal power plants, and its particle size is 3-7 μm.

[0071] The anti-seepage, anti-cracking concrete preparation method comprises the following steps:

[0072](1) Pipette cement, sand, aggregate, fly ash, metakaolin, reinforcing fiber, water-absorbing elastomer, water reducing agent and water according to the preset metering ratio;

[0073] (2) Add 1 / 3 of water to the mix...

Embodiment 2

[0079] A kind of anti-seepage, anti-cracking concrete, its raw material comprises following components:

[0080]

[0081] Wherein, the reinforcing fibers are polypropylene plastic fibers, which are formed by mixing polypropylene fibers with a length of 3.5 to 5 mm and a length of 7 to 8 mm in a ratio of 2:1; the particle size of the sand is 0.25 ~0.5mm, the aggregate is mixed with coarse aggregate with a particle size of 2.36~9.5mm and fine aggregate with a particle size of 0.15~2.36mm according to the ratio of 1:2; the pulverized coal The ash is obtained by grinding by-products of coal combustion in thermal power plants, and its particle size is 3-7 μm.

[0082] The anti-seepage, anti-cracking concrete preparation method comprises the following steps:

[0083] (1) Pipette cement, sand, aggregate, fly ash, metakaolin, reinforcing fiber, water-absorbing elastomer, water reducing agent and water according to the preset metering ratio;

[0084] (2) Add 1 / 3 of water to the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com