Flanging device for container manufacturing

A technology for flanging and container, which is applied to the field of flanging devices for making containers, can solve the problems of high labor intensity, low flanging arc accuracy, low work efficiency, etc., achieves good flanging effect, realizes stepless speed regulation, and improves production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

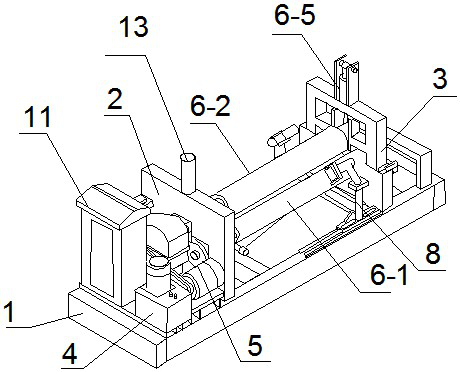

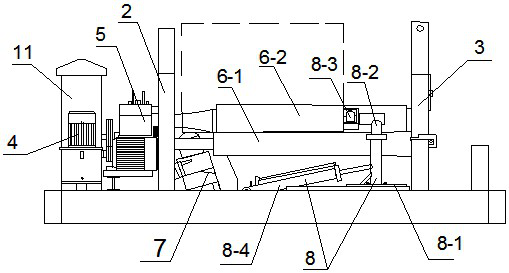

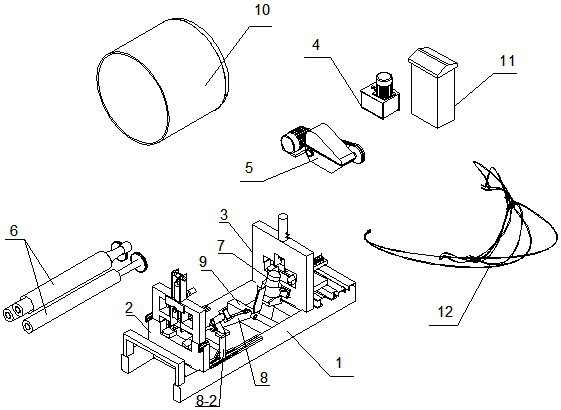

[0057] A flanging device for container production, which consists of: a support system, a rolling system, a push system and a control system, and is characterized in that: the support system consists of a support base 1, a head support frame 2 and a tail support frame 3, the head support frame and the tail support frame are connected with the three work rolls on the rolling system, wherein the head support frame is welded by seamless rectangular steel pipes to form an integral frame, fixed on Just above the transverse support beam at the front end of the supporting base, the supporting frame at the rear is composed of upper and lower structural parts, of which the upper part is a detachable overturning frame, which is welded in the long direction with double channel steel buckles, and can be loaded and unloaded at this position after being laid down Flanged cylinder;

[0058] The rolling system is composed of a motor 4, a reducer 5, three working rolls 6 and a lifting device 1...

Embodiment 2

[0065] According to the container manufacturing flanging device described in Example 1, the support base of the support system is formed by pairing 300*180*8mm seamless rectangular steel pipes, and the described head support frame is formed by 300*180*8mm seamless Seam rectangular steel pipes are welded to form an overall frame, which is a non-detachable part. The lower structure of the tail support frame is a 300*180*8mm seamless rectangular steel pipe fixed directly above the beam of the rear support base, which is a non-detachable part. The joints of the two structures are welded with steel plates and locked with bolts at the front and rear to avoid serial movement when the device is running.

Embodiment 3

[0067] According to the container making flanging device described in embodiment 1 or 2, the outer diameter of the lower roller is 180mm, the diameter of the shaft end is 100mm, and the Y160M-4 three-phase asynchronous motor is connected with the reducer by a V-belt. The first level of speed reduction, the reducer uses the cylindrical output gear and the straight teeth of the two lower rollers to engage with each other to perform the second level of speed reduction, and ensures that the two lower rollers run in the same direction and at the same speed, and the lower roller drives the rollers through electric drive. The outer diameter of the upper roll is 300mm. Since the end of the upper roll is a tapered structure, it can ensure that there is a sufficient distance between the shaft end of the upper roll and the shaft end of the lower roll to meet the space distance required for flanging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer circle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com