Energy-saving and environment-friendly thick plate glass float production process

A technology of energy saving, environmental protection and production process, applied in glass furnace equipment, glass manufacturing equipment, glass cutting device and other directions, can solve the problem of difficult preparation of raw materials, and achieve the effect of reducing repeated heating, improving quality and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

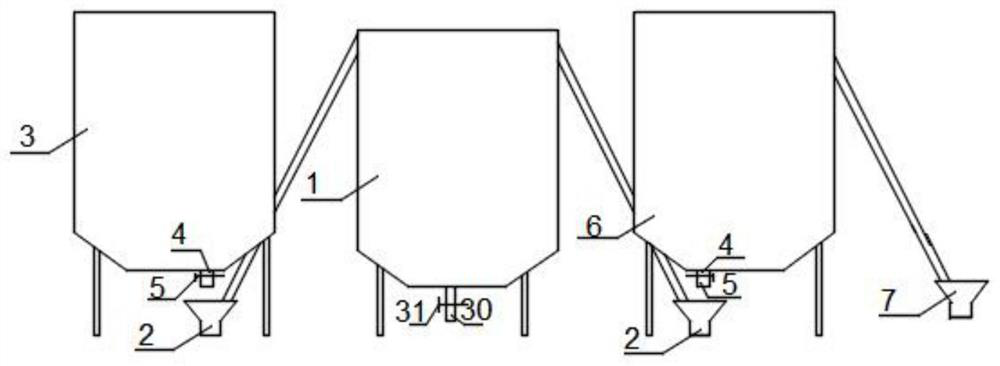

[0041] An energy-saving and environment-friendly thick plate glass float production system, comprising: a storage bin 1, a first bin 3, a second bin 6, and a processing box 8;

[0042] The storage bin 1 is connected with two first bucket elevators 2, one first bucket elevator 2 is provided with a first bin 3, and the other first bucket elevator 2 is provided with a second bin 6 , both the first silo 3 and the lower part of the second silo 6 are provided with a discharge pipe 4, and the discharge pipe 4 is provided with a first control valve 5;

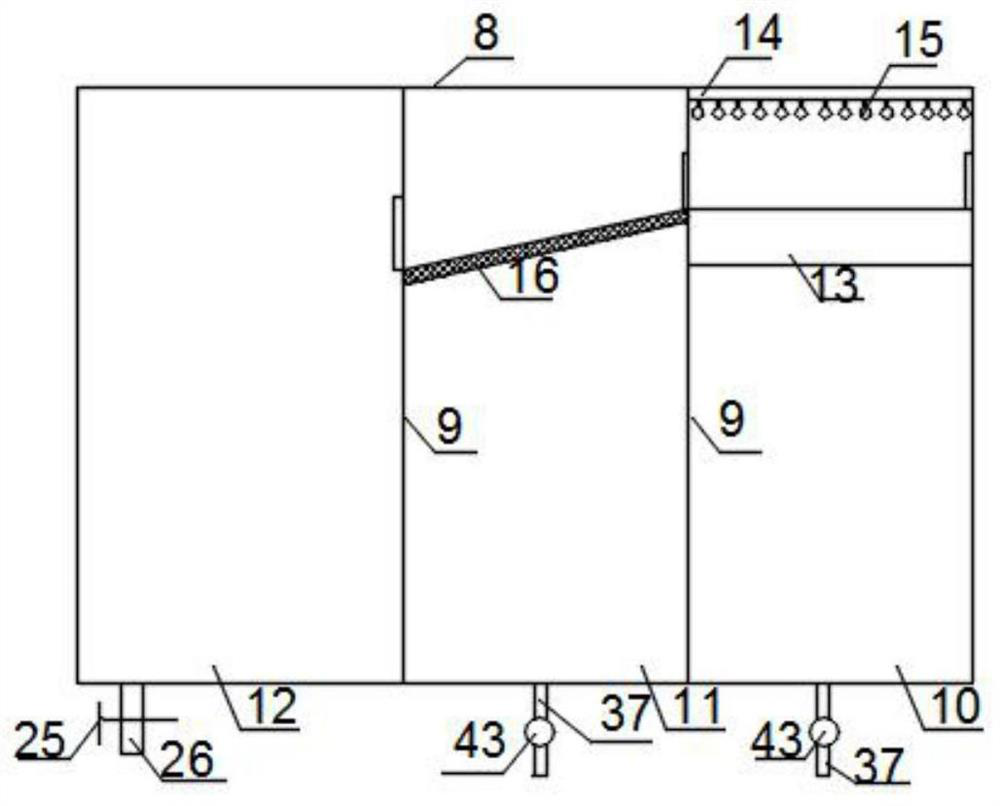

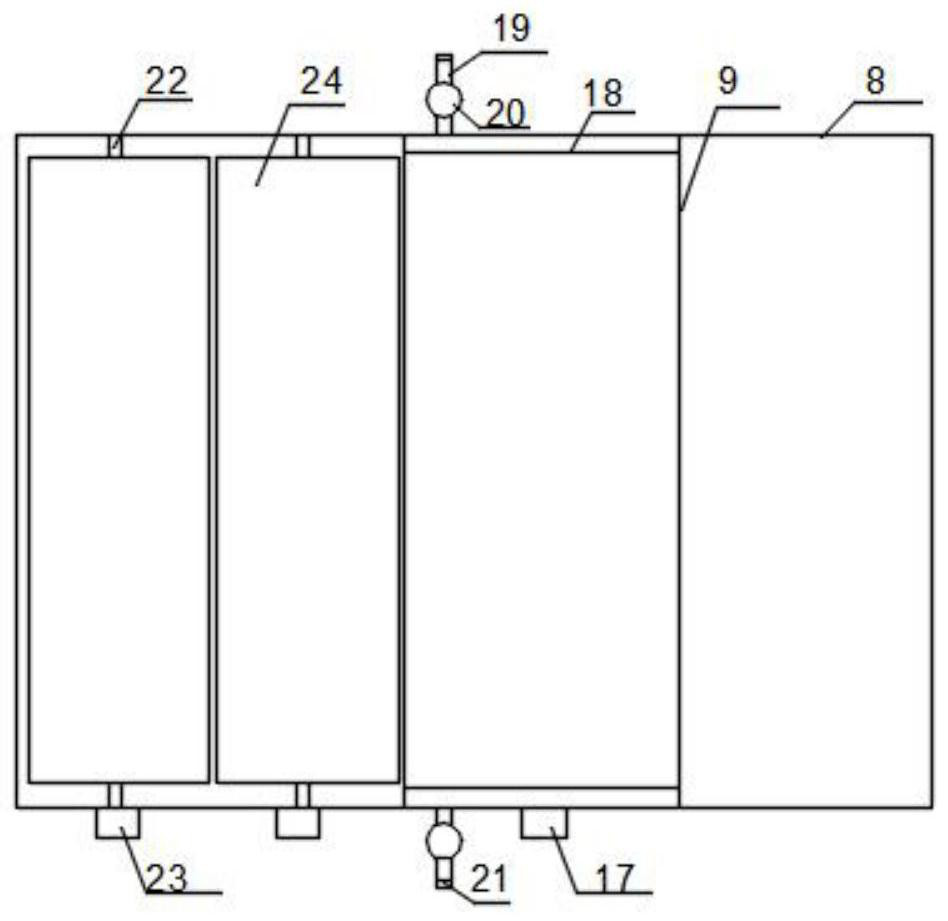

[0043] The second feed bin 6 is connected with a second bucket elevator 7, and the second bucket elevator 7 is provided with a treatment box 8; one end of the treatment box 8 has a feed port, and two vertical compartments are arranged in the treatment box 8 The plate 9 and the partition 9 divide the processing box 8 into a dust removal chamber 10, a drying chamber 11 and a crushing chamber 12, and the vertical partition 9 is provided w...

Embodiment 2

[0047] On the basis of Embodiment 1, a rotating shaft 22 is arranged in the crushing chamber 12, and the rotating shaft 22 is connected with a rotating motor 23, and a crushing roller 24 is arranged on the rotating shaft 22;

[0048] The lower part of the treatment box 8 at the crushing chamber 12 is connected with an output pipe 25, and the second control valve 26 is arranged on the output pipe 25; the dried glass enters the crushing chamber 12, and the crushing roller 24 installed in the crushing chamber 12 is crushed for easy crushing. Then make glass.

Embodiment 3

[0050] On the basis of Embodiment 1-2, a driving shaft 27 is arranged in the storage bin 1, and a stirring paddle 28 is arranged on the driving shaft 27, and the driving shaft 27 is connected with a driving motor 29;

[0051] A feed pipe 30 is connected to the lower part of the storage bin 1, and a third control valve 31 is arranged on the feed pipe 30;

[0052] The lower part of the storage bin 1 is provided with a third bucket elevator 32, and one end of the third bucket elevator 32 is installed in the melting kiln 33; the materials in the storage bin 1 are mixed and stirred, so that the components of the materials entering the melting kiln 33 are uniform .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com