Long-activation-period water-based two-component polyurethane curing agent as well as preparation method and application thereof

A two-component polyurethane technology with long activation period, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as excessive steric hindrance and difficult reaction, slow down the reaction speed, increase activation time, and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of water-based two-component polyurethane curing agent

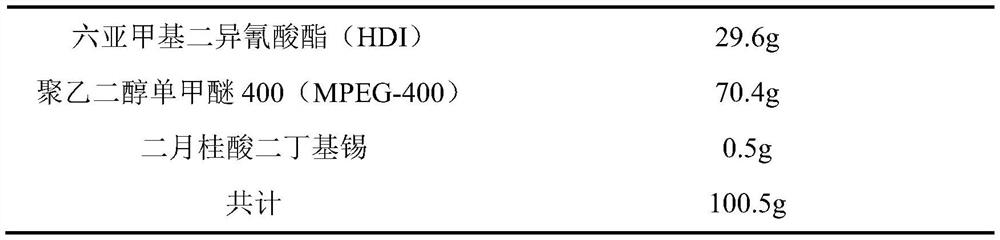

[0049] Raw material composition and consumption are as follows table 1:

[0050] Table 1

[0051]

[0052] Preparation process: Under the protection of nitrogen, transfer HDI, MPEG-400, and dibutyltin dilaurate to a four-necked round-bottomed flask equipped with mechanical stirring, reflux tube, thermometer, and nitrogen inlet and outlet, and raise the temperature of the above mixture to 80°C for reaction 3h, when the NCO content of the system reaches the theoretical value, cool down to 50°C and keep for 30min, cool to room temperature and then discharge.

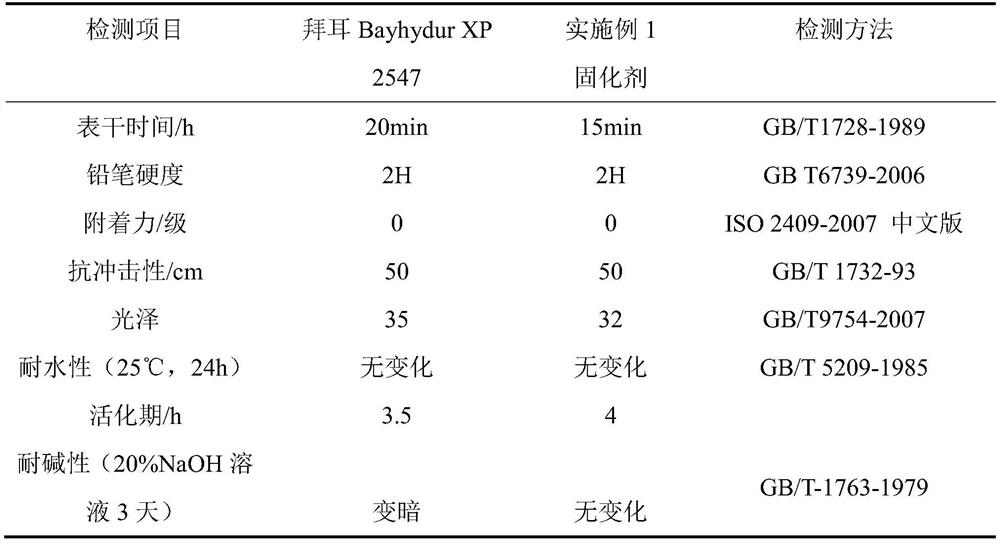

[0053] (2) Preparation of two-component water-based paint: mix the above-mentioned components with Bayhydur XP 2487 according to the quality of the long-potency water-based two-component polyurethane curing agent raw material of 3%, and make a long-potency water-based two-component polyurethane Hardener.

[0054] Performance of water-based...

Embodiment 2

[0068] (1) Preparation of water-based two-component polyurethane curing agent

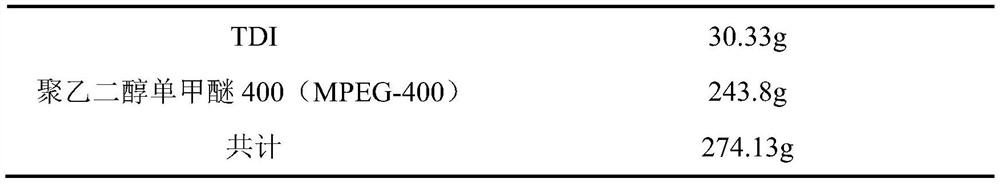

[0069] Raw material composition and consumption are as follows table 3:

[0070] table 3

[0071]

[0072] Preparation process: Under the protection of nitrogen, transfer TDI and MPEG-400 to a four-necked round bottom flask equipped with mechanical stirring, reflux tube, thermometer and nitrogen inlet and outlet, and raise the temperature of the above mixture to 50°C for 2 hours to reach the NCO content of the system When the theoretical value is reached, keep warm for 30 minutes, cool to room temperature and discharge.

[0073] (2) Preparation of two-component water-based paint: mix the components prepared above with Bayhydur XP 2487 according to the quality of the long-potency water-based two-component polyurethane curing agent raw material of 5%, and make a long-potency water-based two-component polyurethane Hardener.

[0074] Performance of water-based polyurethane curing agent: solid con...

Embodiment 3

[0080] (1) Preparation of water-based two-component polyurethane curing agent

[0081] Raw material composition and consumption are as follows table 5:

[0082] table 5

[0083]

[0084] Preparation process: under the protection of nitrogen, transfer IPDI, MPEG-550 and dibutyltin dilaurate to a four-neck round bottom flask equipped with mechanical stirring, reflux tube, thermometer and nitrogen inlet and outlet, and then raise the temperature to 80°C React for 3 hours. When the NCO content in the system reaches the theoretical value, cool down to 50°C and keep for 30 minutes. Cool to room temperature and discharge.

[0085] (2) Preparation of two-component water-based paint: mix the above-mentioned components with Bayhydur XP 2655 according to the quality of the long-potency water-based two-component polyurethane curing agent raw material of 2.5%, and make a new long-potency water-based two-component Polyurethane curing agent.

[0086] Performance of water-based polyuret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com