Temperature measuring device of vacuum precision casting furnace

A technology of precision casting and temperature measurement device, applied in the metallurgical field, can solve the problems of inability to accurately test the temperature, affect the production efficiency, low casting molding rate, etc., and achieve the effect of avoiding long measurement time, improving production efficiency, and saving maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example ;

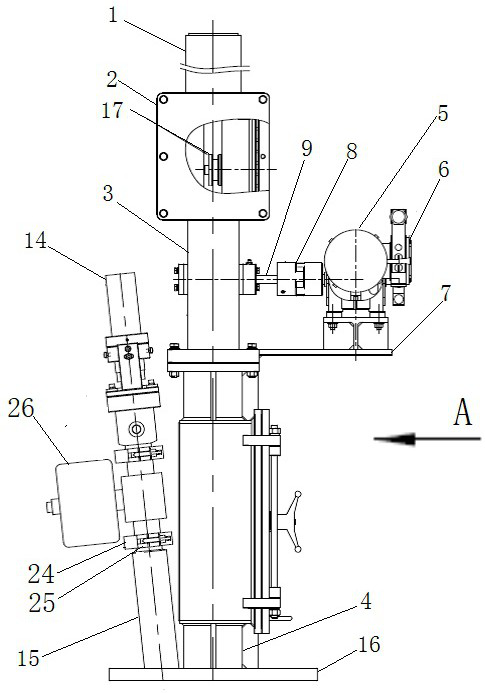

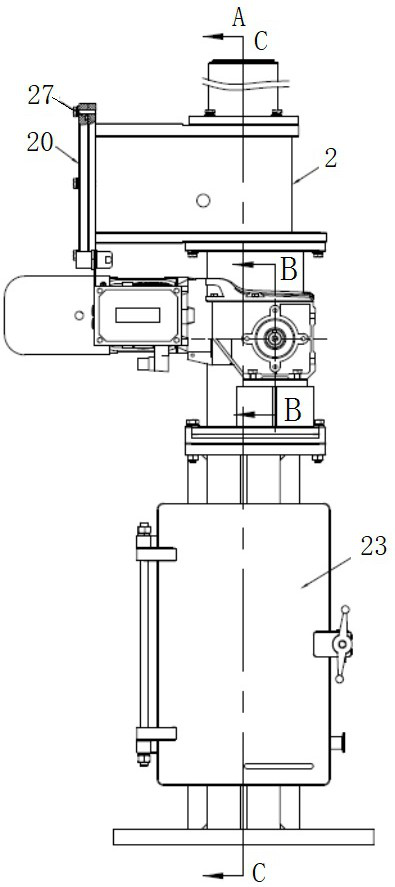

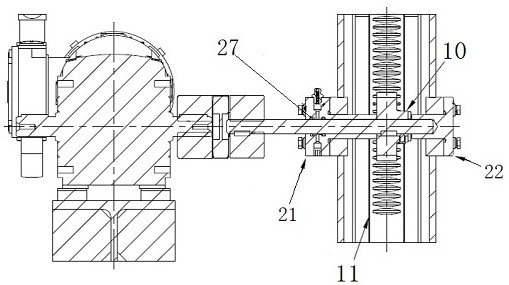

[0067] Such as figure 1 As shown, the present invention provides a vacuum precision casting furnace temperature measuring device, comprising: a first temperature measuring component and a second temperature measuring component;

[0068] The first temperature measurement component includes: an upper chamber 1, a wiring chamber 2, a transmission chamber 3 and a lower chamber 4 arranged in sequence from top to bottom and sealed and fixedly connected;

[0069] The power source 5, the sensor 6 and the controller (not shown in the figure) are fixed on the bracket 7 beside the transmission cavity. The sensor 6 detects the output of the power source 5 and feeds it back to the controller. The controller controls the output of the power source according to the signal of the sensor 6. The power source is connected to the drive shaft 9 through the coupling 8, and the drive shaft 9 is keyed to the transmission gear 10 located in the transmission cavity 3. The transmission gear 10 meshes to...

no. 2 example ;

[0072] Such as Figure 1-Figure 4 As shown, the present invention provides a vacuum precision casting furnace temperature measuring device, comprising: a first temperature measuring component and a second temperature measuring component;

[0073] The first temperature measurement component includes: an upper chamber 1, a wiring chamber 2, a transmission chamber 3 and a lower chamber 4 arranged in sequence from top to bottom and sealed and fixedly connected;

[0074] The transmission chamber 3 and the lower chamber 4 are connected with an O-ring 33 by bolts, and the transmission chamber 3 and the wire collection chamber 2 are connected with an O-ring 32 by bolts, and the wire collection chamber 2 is connected with the upper The chamber body 1 is connected with an O-ring by bolts, and a chamber cover 20 is formed on one side wall of the cable collection chamber body 2, and the chamber body cover 20 is sealed and fixed by the bolts and the O-ring.

[0075] The power source 5, th...

no. 3 example ;

[0087] The third embodiment of the present invention is implemented based on the hardware structure of the above-mentioned first embodiment or the second embodiment, and the repeated parts will not be repeated;

[0088] Wherein, the controller performs the following repeated temperature measurement control on the control power source output according to the temperature measured by the first temperature measurement component and the temperature measured by the second temperature measurement component;

[0089] The controller controls the first temperature measuring component and the second temperature measuring component to measure the temperature simultaneously or sequentially within the first period; the second period should not be too long, and it is suggested that the first period ranges from 1 to 120 seconds. Since the second temperature measuring component is an optical thermometer (such as an infrared thermometer), the temperature collected by it is sent to the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com