ZnMn2O4 negative electrode material as well as preparation method and application thereof

A negative electrode material and mixed salt technology, applied in the field of ZnMn2O4 negative electrode materials, can solve the problems of high cost and complicated preparation process, and achieve the effects of improving cycle performance, abundant natural resources, and alleviating volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a ZnMn 2 o 4 The preparation method of negative electrode material, described preparation method comprises:

[0039] (1) Zinc sulfate and manganese sulfate according to ZnMn 2 o 4 The stoichiometric ratio was weighed and dissolved in 5mL of deionized water to form a mixed salt solution, and the sucrose and the mixed salt solution were mixed and dissolved to obtain a mixed solution. The quality of the sucrose was 25% by weight of the mixed salt solution;

[0040] (2) Transfer the mixed liquid to a porcelain boat, put the porcelain boat into a blast drying device for drying treatment, the drying temperature is 60°C, and the drying time is 3h. When a film is formed on the surface of the mixed liquid, transfer the porcelain boat To the muffle furnace for annealing treatment, the annealing temperature is 500 ° C, the annealing time is 3h, after annealing to get ZnMn 2 o 4 Negative material.

Embodiment 2

[0042] This embodiment provides a ZnMn 2 o 4 The preparation method of negative electrode material, described preparation method comprises:

[0043] (1) Zinc chloride and manganese chloride according to ZnMn 2 o 4 The stoichiometric ratio was weighed and dissolved in 5mL deionized water to form a mixed salt solution, and the sucrose and the mixed salt solution were mixed and dissolved to obtain a mixed solution. The quality of the sucrose was 27% by weight of the mixed salt solution;

[0044] (2) Transfer the mixed liquid to a porcelain boat, put the porcelain boat into a blast drying device for drying treatment, the drying temperature is 64°C, and the drying time is 2.8h. When a film is formed on the surface of the mixed liquid, put the porcelain boat Transfer to the muffle furnace for annealing treatment, the annealing temperature is 540°C, the annealing time is 2.6h, after annealing, ZnMn 2 o 4 Negative material.

Embodiment 3

[0046] This embodiment provides a ZnMn 2 o 4 The preparation method of negative electrode material, described preparation method comprises:

[0047] (1) Zinc nitrate and manganese nitrate according to ZnMn 2 o 4 The stoichiometric ratio was weighed and dissolved in 5mL of deionized water to form a mixed salt solution, and the sucrose and the mixed salt solution were mixed and dissolved to obtain a mixed solution. The quality of the sucrose was 29% by weight of the mixed salt solution;

[0048] (2) Transfer the mixed liquid to a porcelain boat, put the porcelain boat into a blast drying device for drying treatment, the drying temperature is 68°C, and the drying time is 2.6h. When a film is formed on the surface of the mixed liquid, put the porcelain boat Transfer to the muffle furnace for annealing treatment, the annealing temperature is 580°C, the annealing time is 2.2h, after annealing, ZnMn 2 o 4 Negative material.

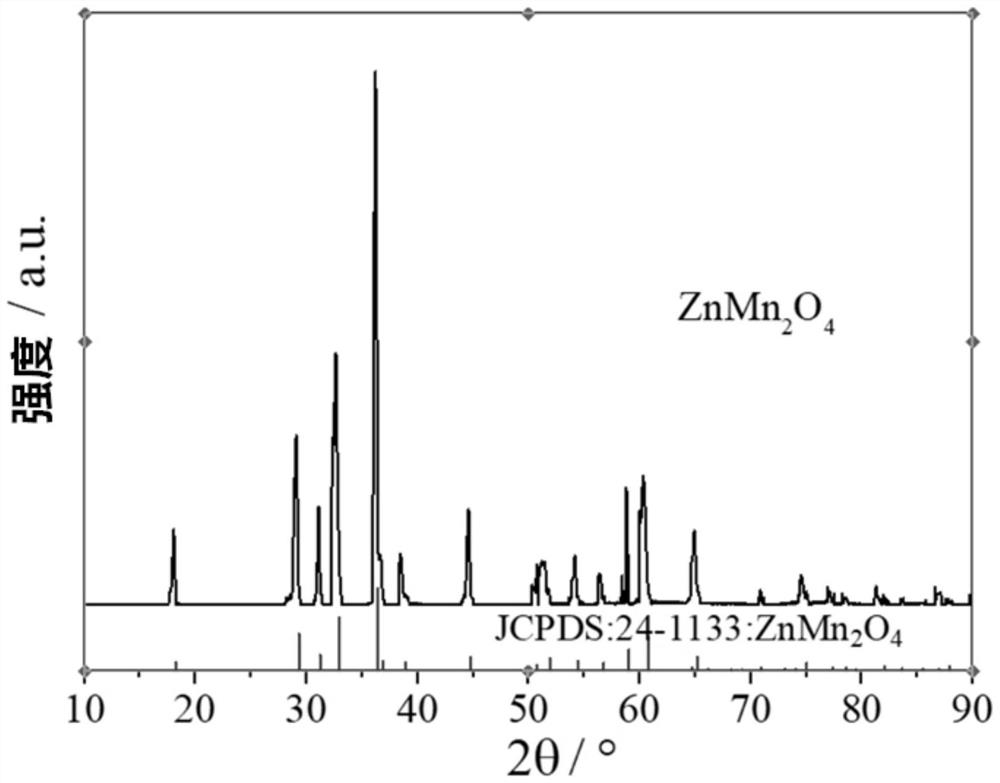

[0049] Prepared ZnMn 2 o 4 The XRD pattern of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com