Preparation method of high-density NMN

A high-density, bulk density technology, applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of low bulk density and poor fluidity, and achieve the effect of improving product yield and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

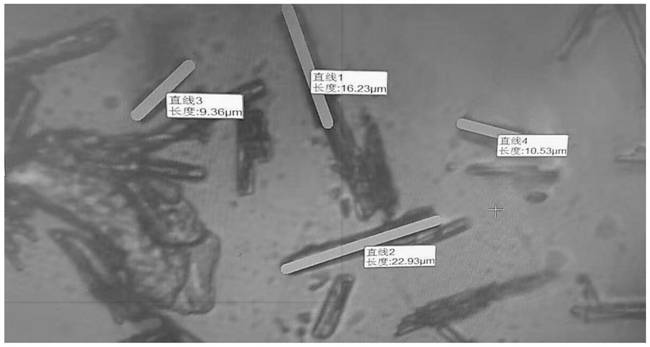

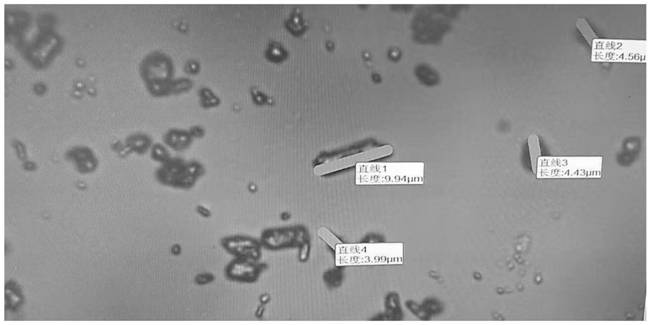

[0018] see Figure 1-2 , the present invention provides a technical solution: a preparation method of high-density NMN, the specific steps are as follows:

[0019] Step 1: After continuously adding a poor solvent to the aqueous solution of NMN, a water-containing NMN oily layer is formed;

[0020] Step 2: Then repeatedly beat the oil layer with a poor solvent to dilute the water content in the oil layer and slowly transform it into a white powder;

[0021] Step 3: After filtering and drying, the particle shaker is crushed and passed through a 40-80 mesh sieve, which is NMN with high bulk density.

[0022] The NMN aqueous oil layer in the step one has a water content of 5-20%, and the poor solvent in the step one is any one of ethanol, methanol, Virahol, acetonitrile and DMF, and the The consumption of poor solvent is 5-10 times of volume ratio of aqueous solution, and the consumption of the water used in described step 1 is 2-10 times of solid weight, and the beating times o...

Embodiment 1

[0026] Weigh 100g of low-density NMN finished product and dissolve it in 500mL of water to obtain a colorless and transparent NMN aqueous solution. Slowly add 2L of absolute ethanol to the aqueous solution. With the increase of ethanol, the solution first becomes an emulsion, and finally separates into two phases of oil and water. The upper layer is the ethanol water phase, and the lower layer is the oil phase formed by NMN and water. After the oil phase was separated through a separatory funnel, 1 L of absolute ethanol was added to the oil phase, and stirred for 1 hour to obtain a colorless viscous liquid. After filtration, 1 L of ethanol was added to the solid layer, stirred for one hour, and a white sandy solid was obtained by filtration. The white solid was lyophilized and weighed to obtain 98 g of the product. After the solid passes through a 60-mesh sieve, the bulk density is measured after detection: the bulk density is 0.52g / mL, and the tap density is 0.71g / mL.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com