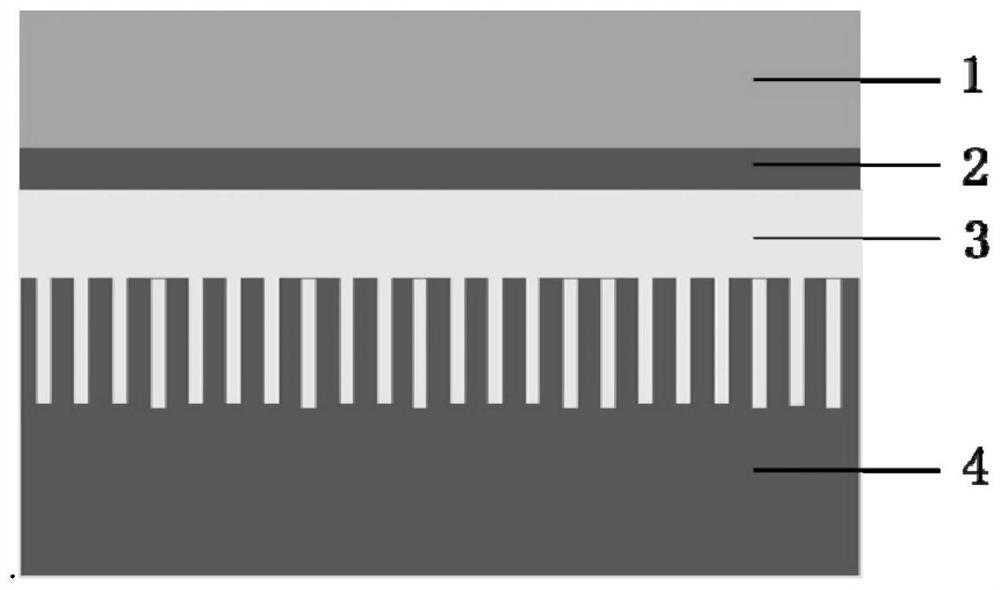

A large-area graphene-based flexible substrate and preparation method thereof

A vinyl-based flexible and large-area technology, applied in vacuum evaporation plating, coating, sputtering plating, etc., to achieve the effects of commercialization, excellent flexibility and bending resistance, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

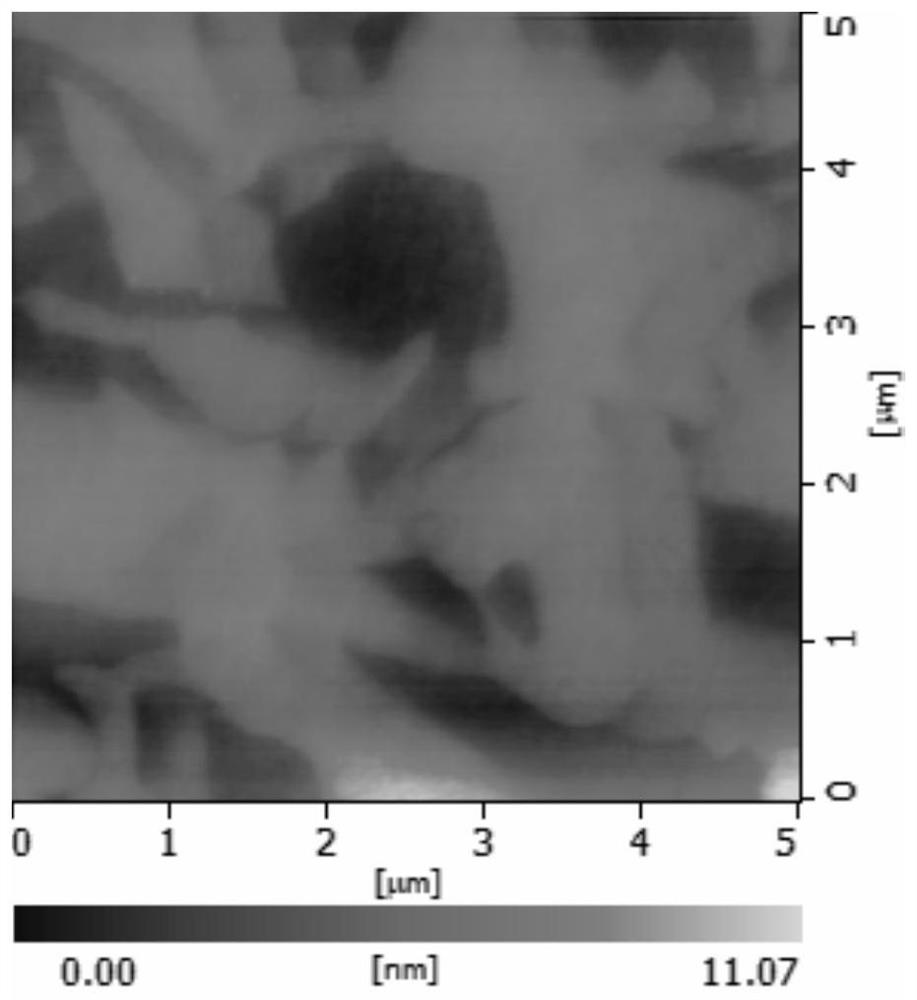

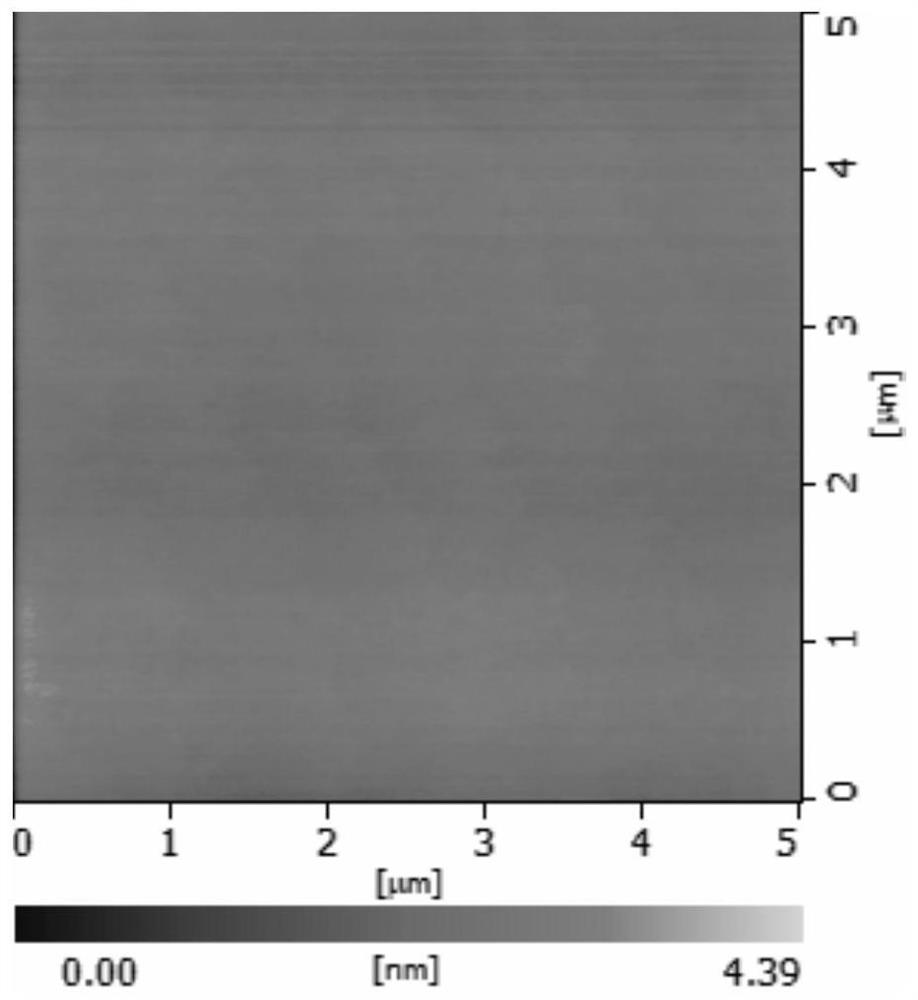

Image

Examples

Embodiment 1

[0037] A Pt / Ag / large-area graphene composite flexible substrate, the preparation method of which is:

[0038] 1. Preparation of Large Graphene Flexible Films

[0039] The suspension of commercial graphene oxide was diluted to a concentration of 1 mg / mL with ultrapure water with a resistivity of 18.25 MΩ cm and centrifuged. Take the bottom 20% volume solution, dilute to 1 mg / mL, and centrifuge again to enter the next cycle. Repeat the above operation 7 times, take the final 20% volume solution at the bottom, concentrate it into a 10mg / mL graphene oxide gel, scrape it on the surface of the PET film, and after vacuum drying for 24 hours, a large graphene oxide film is formed on the PET film , to separate the large graphene oxide film from the PET film.

[0040] A large piece of graphene oxide film is placed in a graphite high-temperature furnace, first carbonized at 1300°C for 5 hours in an inert argon atmosphere, and then heat-treated at 2800°C for 2 hours. After cooling, it ...

Embodiment 2

[0050] A kind of ITO / Ag / large-area graphene composite flexible substrate, its preparation method is:

[0051] 1. Preparation of Large Graphene Flexible Films

[0052] The suspension of commercial graphene oxide was diluted to a concentration of 2 mg / mL with ultrapure water with a resistivity of 18.25 MΩ cm and centrifuged. Take the bottom 30% volume solution, dilute to 2mg / mL, and centrifuge again to enter the next cycle. Repeat the above operation 7 times, take the final 30% volume solution at the bottom, concentrate it into a 20mg / mL graphene oxide gel, scrape it on the surface of the PET film, and after vacuum drying for 24 hours, a large graphene oxide film is formed on the PET film , to separate the large graphene oxide film from the PET film.

[0053] A large piece of graphene oxide film is placed in a graphite high-temperature furnace, first carbonized at 1200°C for 2 hours in an inert argon atmosphere, and then heat-treated at 3000°C for 1 hour. After cooling, it is...

Embodiment 3

[0063] A FTO / Ag / large-area graphene composite flexible substrate, the preparation method of which is:

[0064] 1. Preparation of Large Graphene Flexible Films

[0065] The suspension of commercial graphene oxide was diluted to a concentration of 5 mg / mL with ultrapure water with a resistivity of 18.25 MΩ cm and centrifuged. Take the bottom 10% volume solution, dilute to 5mg / mL, and centrifuge again to enter the next cycle. Repeat the above operation 7 times, take the final 10% volume solution at the bottom, concentrate it into a 50mg / mL graphene oxide gel, scrape it on the surface of the PET film, and dry it in vacuum for 24 hours to form a large graphene oxide film on the PET film , to separate the large graphene oxide film from the PET film.

[0066] A large sheet of graphene oxide film is placed in a graphite high-temperature furnace, first carbonized at 1100°C for 3 hours in an inert argon atmosphere, and then heat-treated at 3500°C for 0.5 hour. After cooling, it is fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com