Production process of bracket-free invisible appliance

An invisible aligner and production process technology, applied in the field of orthodontics, can solve problems such as aligner burrs and cutter passivation, and achieve the effect of avoiding burrs and avoiding passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

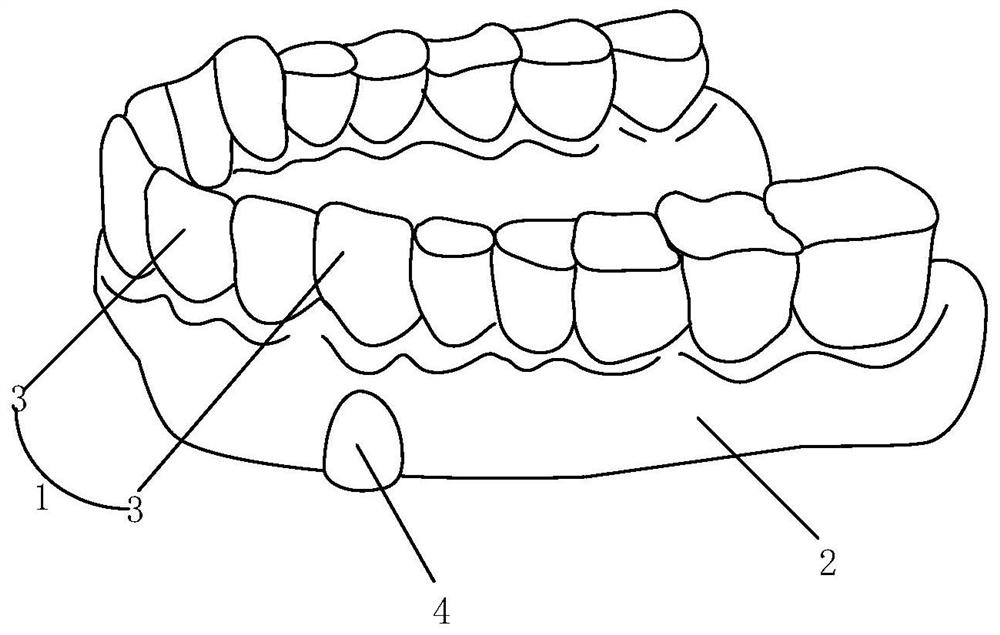

Image

Examples

Embodiment 1

[0026] The present embodiment provides a production process of a bracketless invisible aligner, the production process comprising the following steps:

[0027] S1. heating and softening the polymer membrane, and hot-pressing the film on the tooth model to obtain a molded membrane that wraps the tooth model;

[0028] S2. Transporting the formed film to the cutting area for cutting and separating the tooth model to obtain a bracket-free invisible appliance;

[0029] Infrared heating is performed on the formed film obtained in step S1 during the process of transporting the formed film to the cutting area.

[0030] There is a flow time in the process of transferring the formed diaphragm wrapped with the tooth model obtained in step S1 to the cutting area in step S2, and the formed diaphragm will be cooled due to the flow time, so that the formed diaphragm will be easy to cut when performing subsequent cutting. Burrs are generated, and the cutting blade will be easily passivated; ...

Embodiment 2

[0032] As in the production process described in Example 1, infrared heating is performed on the formed film during the cutting process in step S2. Furthermore, the entire cutting process is carried out in infrared heating to avoid the cooling of the diaphragm due to the long cutting process, so that the diaphragm is kept at a certain temperature during the cutting process, so that cutting will not produce burrs and the cutting blade will not passivate.

Embodiment 3

[0034] As in the production process described in Embodiment 1 or 2, during the process of transporting to the cutting area or during the process of cutting, the formed film is heated by infrared to a temperature lower than its melting point. In this way, the infrared heating temperature is too high to cause deformation of the formed diaphragm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com