Preparation method of polycrystalline alumina self-assembled octahedral particles

A polycrystalline alumina, self-assembly technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, aluminum compounds, etc., can solve the problem that the distribution ratio of oxide crystal planes has no obvious effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]After 15 grams of Sb powder, the ball grinding was ground into a fine powder, and the powder was selected from about 5,000 mesh, and the aniline solution was prepared, and then adsorbed on the alumina precursor powder, and the amount of aniline was calcined. 4% of the amount of alumina precursor. After drying at 120 ° C, the material is placed in a closed system, the lower portion of the closed system is 25 g / L an aniline solution, and the upper portion is the above-mentioned alumina precursor, the solid phase is not directly in direct contact with the liquid phase.

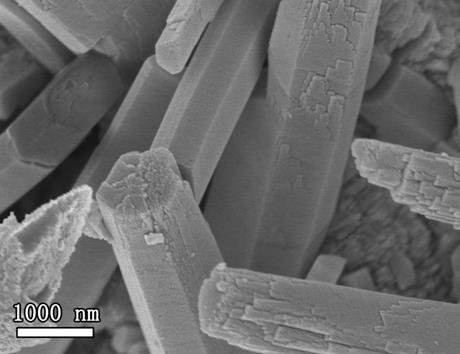

[0027]The heating closed system 250 ° C, water heat treatment for 24 hours. The removal product was then naturally cooled, and then dried at 120 ° C for 4 hours at 550 ° C to obtain the product. The scanning electron microscope is observed that the product morphology is a six-prism-like octahedral particle shape, has an octahedral perspective morphology of approximately regular, divided into 4 groups, each set of ...

Embodiment 2

[0029]After 15 grams of SB powder, the ball mill was ground into a fine powder, and the powder of about 10,000 titles was selected, and the aniline solution was prepared, and then adsorbed on the alumina precursor powder, and the amount of aniline was calcined. The amount of alumina precursor is used for 2.5%. After drying at 120 ° C, the material is placed in a closed system, and the lower portion of the closed system is 20 g / L an aniline solution, and the upper portion is the above-treated alumina precursor, the solid phase is not directly in contact with the liquid phase.

[0030]The heating closing system was 200 ° C, water heat treatment for 36 hours. The removal product was then naturally cooled, and then dried at 120 ° C for 4 hours at 550 ° C to obtain the product. The scanning electron microscope is observed that the product morphology is a six-prism-like octahedral particle shape, has an octahedral perspective morphology of approximately regular, divided into 4 groups, each...

Embodiment 3

[0032]After 15 g of silicon-modified SB powder, the ball mill was ground into a fine powder, and the powder was selected from the powder, and the ethanolamine solution was prepared, and then adsorbed in an alumina precursor powder, aniline The amount of aluminum oxide precursor amount after calcination is 6%. After drying at 120 ° C, the material is placed in a closed system, and the lower portion of the closed system is 20 g / L an aniline solution, and the upper portion is the above-treated alumina precursor, the solid phase is not directly in contact with the liquid phase.

[0033]The heating closing system was 200 ° C, and the water was treated for 12 hours. The removal product was then naturally cooled, and then dried at 120 ° C for 4 hours at 550 ° C to obtain the product. The scanning electron microscope is observed that the product morphology is a six-prism-like octahedral particle shape, has an octahedral perspective morphology of approximately regular, divided into 4 groups, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com