Synthesis method of lansoprazole

A synthesis method and technology of lansoprazole, applied in the field of lansoprazole synthesis, can solve the problems of low total molar yield, excess metal elements of finished products, instability of lansoprazole and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

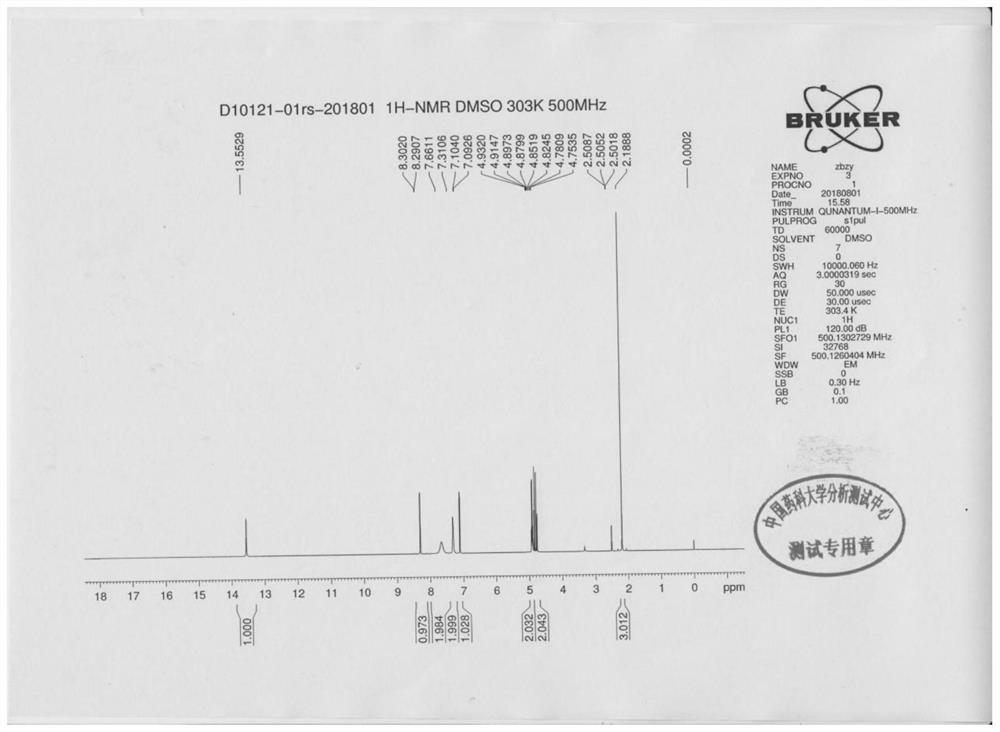

Image

Examples

Embodiment 1

[0048] The preparation of Lansoprazole crude product

[0049] Add 272g of 2-mercaptobenzimidazole, 160g of drinking water and 160g of sodium hydroxide into a 5L reaction flask, and stir at room temperature until it dissolves. Prepare 500g lansoprazole chloride (also the 2-chloromethyl-3-methyl-4-(2,2,2-trifluoroethoxy) pyridine hydrochloride shown in II, following example The same as in ) and 2000g of drinking water solution. Add the aqueous solution of lansoprazole chloride dropwise to the reaction kettle at room temperature, and the dropwise addition time is 1 to 2 hours. After the drop is completed, stir and react at 10°C for 4 hours. Add the lye that 87g sodium hydroxide and 350g drinking water are made into, tetrabutylammonium bromide (TBAB) 17.5g. After finishing the addition, cool down to -10°C and start to drop 1887g of 10% sodium hypochlorite (in terms of available chlorine, that is, the oxidizing power of 1 gram of 10% sodium hypochlorite solution is equivalent to ...

Embodiment 2

[0053] The preparation of Lansoprazole crude product

[0054] Add 68g of 2-mercaptobenzimidazole, 40g of drinking water and 56g of potassium hydroxide into a 2L reaction flask, and stir at room temperature until dissolved. Prepare a solution of 125g lansoprazole chloride and 500g drinking water. Add the aqueous solution of lansoprazole chloride dropwise to the reaction kettle at room temperature for 1 to 2 hours. After the drop is completed, raise the temperature to 60° C. and stir for 1 hour. Cool down to 10°C and add lye made of 22g sodium hydroxide and 88g drinking water, and 8.4g trimethylbenzyl ammonium chloride. After the addition was completed, 472 g of 10% sodium hypochlorite aqueous solution was added dropwise at -10°C, and the dropwise addition time was about 2 hours. After the dropwise addition was completed, samples were taken and analyzed after the reaction at 0° C. for 2 hours, and the residual lansoprazole sulfide was ≤2.0%. A solution of 8.3 g of sodium thio...

Embodiment 3

[0058] The preparation of Lansoprazole crude product

[0059] Add 136g of 2-mercaptobenzimidazole, 80g of drinking water and 112g of potassium hydroxide into a 3L reaction flask, and stir at room temperature until it dissolves. Prepare the solution of 250g lansoprazole chloride and 1000g drinking water. Add the aqueous solution of lansoprazole chloride dropwise to the reaction kettle at room temperature for 1 to 2 hours. After the drop is completed, stir and react at 30°C for 2 hours. Add the lye that 62g potassium hydroxide and 170g drinking water are made into, 15.4g of tetrabutyl ammonium bisulfate. After the addition was completed, the temperature was lowered to -10°C and 944 g of 10% sodium hypochlorite aqueous solution was added dropwise, and the dropwise addition time was about 2 hours. After the dropwise addition was completed, the reaction was incubated at 25° C. for 1.5 h and then sampled for analysis. The residual lansoprazole sulfide was ≤2.0%. Prepare a solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com