Preparation method of epoxy-terminated functionalized solution polymerized styrene-butadiene rubber

A solution-polymerized styrene-butadiene rubber, functionalization technology, applied in the field of rubber, can solve the problems of difficulty in realizing solution-polymerized styrene-butadiene rubber chain end functionalization, low cost, increasing price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

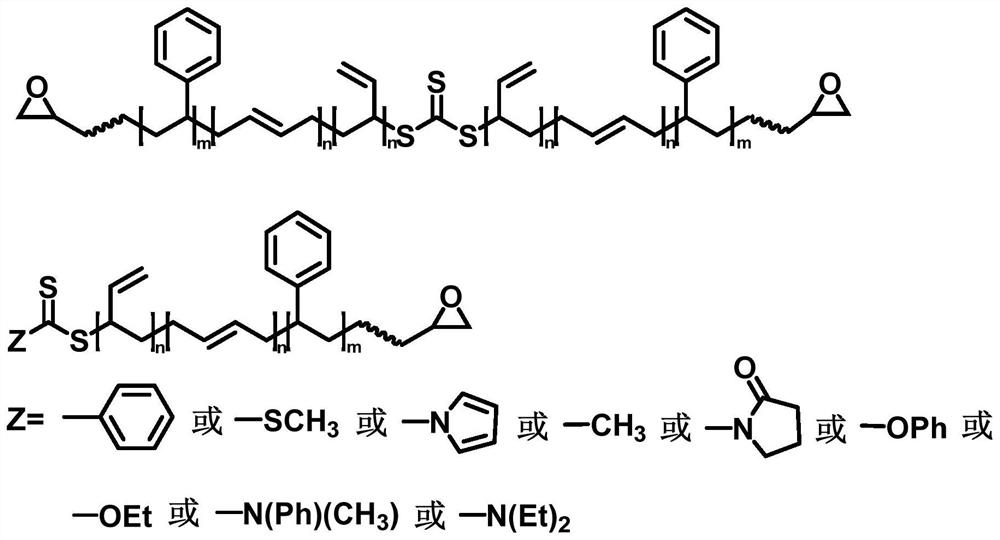

Method used

Image

Examples

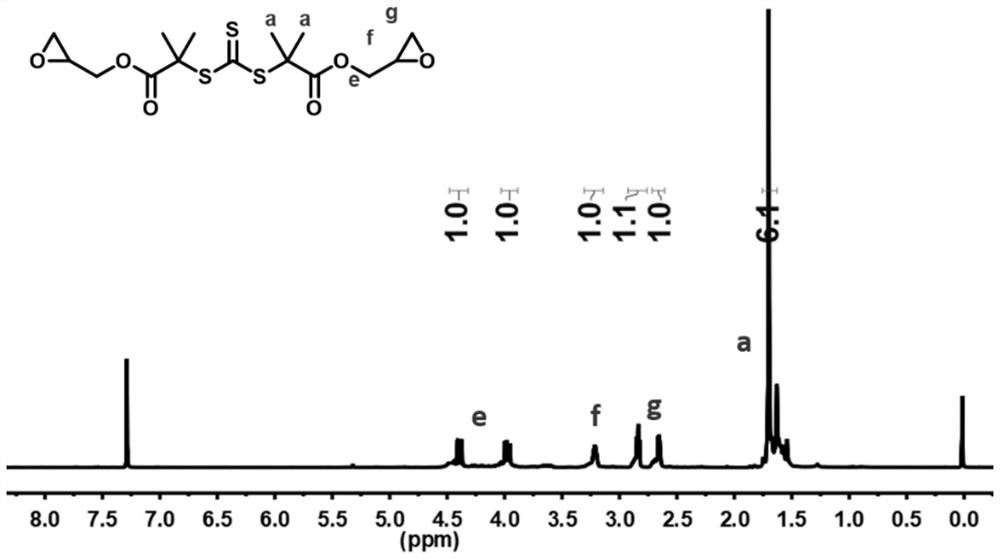

Embodiment example 1

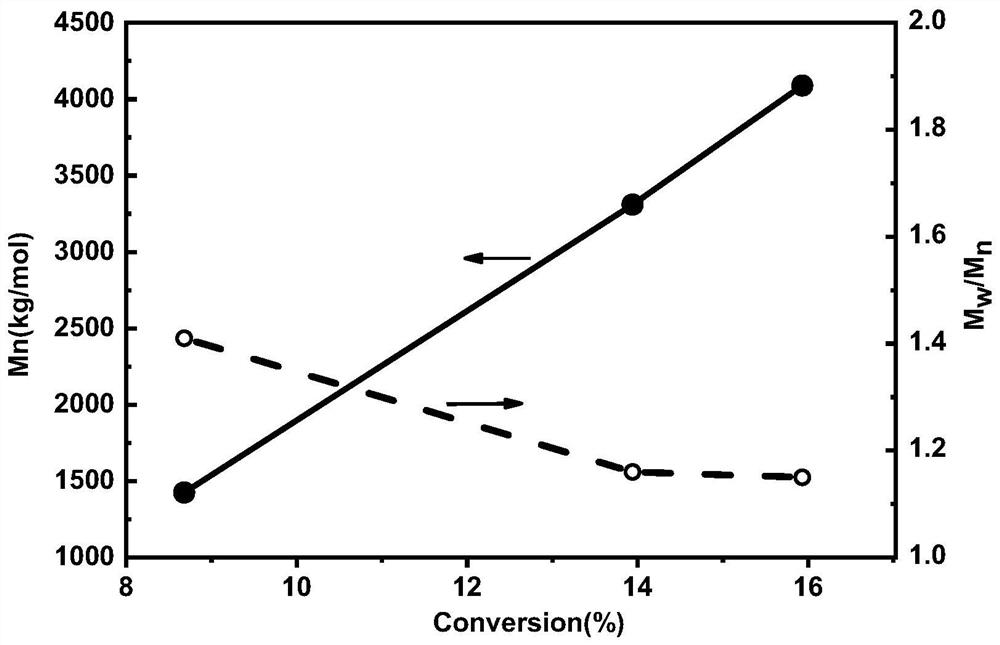

[0016] Take dioxane (40.00mL), styrene (7.00g), butadiene (5.00g), RAFT reagent (BODAAT, 0.33g), di-tert-butyl peroxide (0.024g) into 100mL stainless steel high temperature In a high-pressure reactor, the reactor headspace is filled with N 2 Rinse 3 times, degas the solution three times, and place the reactor in N 2 Lower seal. The reactor was heated at 95°C for 30 hours with stirring. After completion of the reaction, the reaction mixture was precipitated into methanol (600.00 mL). Use a 15,000-rpm centrifuge to separate the polymer, and dry it in a vacuum oven (25°C, 0.70kPa) to a constant mass to obtain a double-end epoxy-functionalized solution-polymerized styrene-butadiene with a mass fraction of 23% and a molecular weight of 2300. rubber.

Embodiment example 2

[0018] Get tetrahydrofuran (40.00mL), styrene (11.45g), butadiene (5.00g), RAFT reagent (BODAAT, 0.0975g), azobisisobutyronitrile (0.027g) join in the reactor, the reactor Headspace with N 2 Rinse 3 times, degas the solution three times, and place the reactor in N 2 Lower seal. The reactor was heated at 70° C. for 50 hours with stirring. After completion of the reaction, the reaction mixture was precipitated into methanol (600.00 mL). Use a 15,000-rpm centrifuge to separate the polymer, and dry it in a vacuum oven (25°C, 0.70kPa) to a constant mass to obtain an epoxy-functionalized solution-polymerized styrene-butadiene with a mass fraction of styrene of 65% and a molecular weight of 2,0000 rubber.

Embodiment example 3

[0020] Take dioxane (40.00mL), styrene (0.067mol), butadiene (0.092mol), RAFT reagent (0.836mmol), and azobisisobutyronitrile (0.164mmol) into a 100mL stainless steel high temperature and high pressure reactor , the reactor headspace was filled with N 2 Rinse 3 times, degas the solution three times, and place the reactor in N 2 Lower seal. The reactor was heated at 95°C for 30 hours with stirring. After completion of the reaction, the reaction mixture was precipitated into methanol (600.00 mL). Use a 15,000-rpm centrifuge to separate the polymer, and dry it in a vacuum oven (25°C, 0.70kPa) to a constant mass to obtain a single-end epoxy-functionalized solution-polymerized styrene-butadiene with a mass fraction of 23% and a molecular weight of 2100 rubber.

[0021] The above-mentioned preparation method selects the xanthate RAFT reagent whose single end is an epoxy group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com