High-fluidity, low-odor and scratch-resistant polypropylene material special for automotive interiors and preparation method thereof

A polypropylene material and automotive interior technology, applied in the field of polymer modification processing, can solve a small amount of odor, remove plastic odor and other problems, achieve the effects of delaying aging speed, prolonging the use effect, and improving heat resistance and sunscreen performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

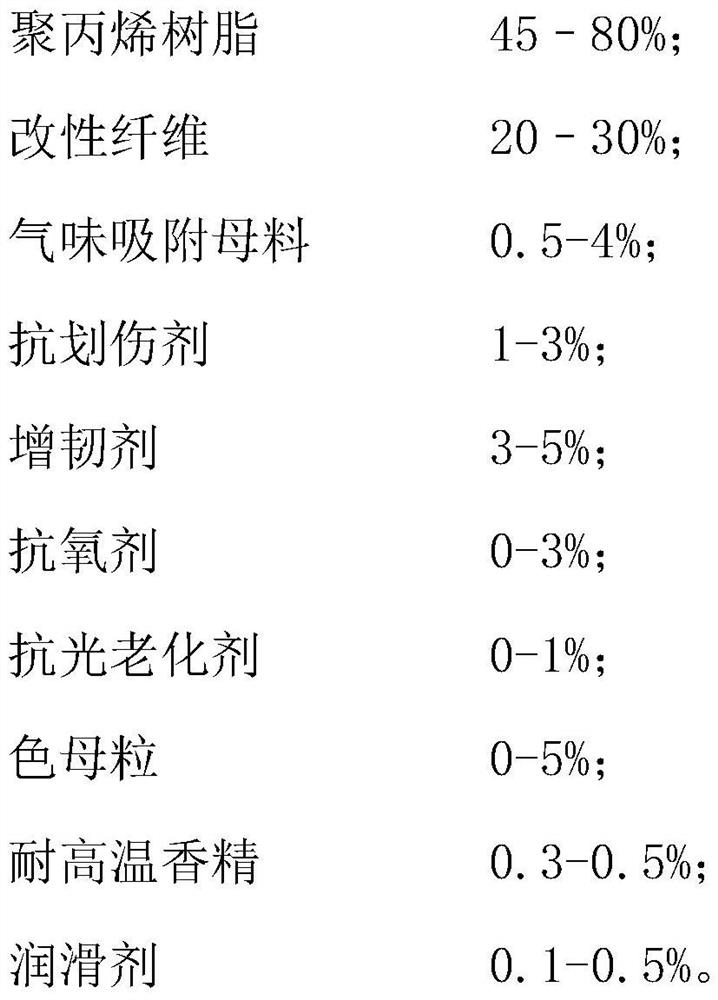

[0027] A high-flow, low-odor, scratch-resistant polypropylene material for automotive interiors, consisting of the following raw materials in parts by weight:

[0028]

[0029]

[0030] Further, the polypropylene resin is selected from a high fluidity copolymerized polypropylene with a melt flow index ≥ 20g / 10min, and its product number is K9928.

[0031] Further, the modified fiber is selected from basalt fiber.

[0032] Further, the odor adsorption masterbatch is activated carbon.

[0033] Further, the anti-scratch agent is prepared from polysiloxane and silicone in a ratio of 2:1.

[0034] Further, the toughening agent is an ethylene copolymer.

[0035] Further, the antioxidant is prepared from a thioester antioxidant and an ester antioxidant at a ratio of 2:1.

[0036] Further, the anti-light aging agent is a hindered amine light stabilizer, and its CAS number is 52829-07-9.

[0037] Further, the high-temperature-resistant essence is sandalwood essence, its high-...

Embodiment 2

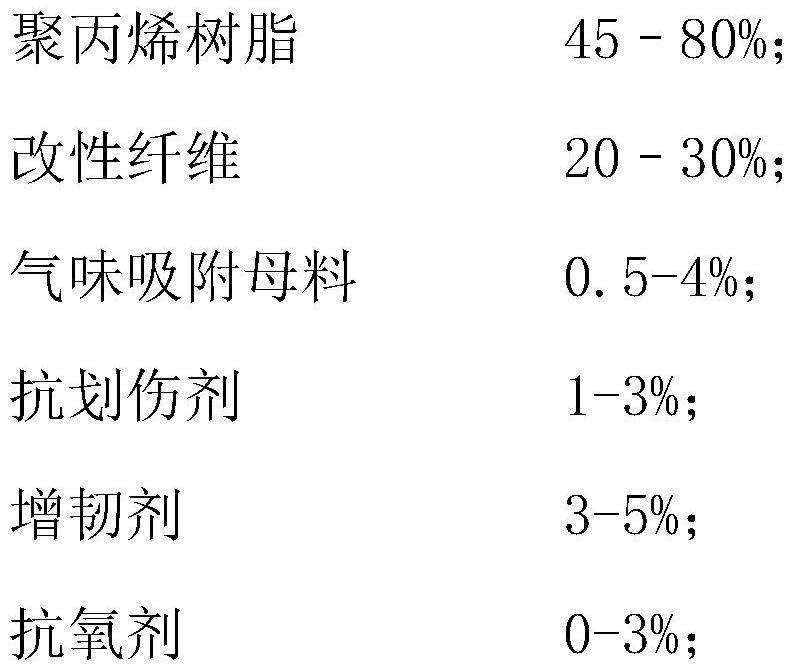

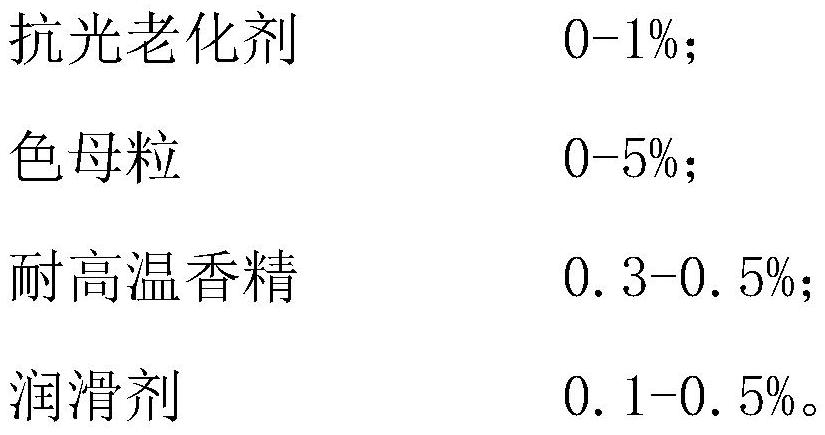

[0044] A high-flow, low-odor, scratch-resistant polypropylene material for automotive interiors, consisting of the following raw materials in parts by weight:

[0045]

[0046] Further, the polypropylene resin is selected from a high fluidity copolymerized polypropylene with a melt flow index ≥ 20g / 10min, and its product number is K9928.

[0047] Further, glass fiber is selected as the modified fiber.

[0048] Further, the odor adsorption masterbatch is diatomaceous earth.

[0049] Further, the anti-scratch agent is prepared from polysiloxane and silicone in a ratio of 2:1.

[0050] Further, the toughening agent is a propylene copolymer.

[0051] Further, the antioxidant is prepared from a thioester antioxidant and an ester antioxidant at a ratio of 2:1.

[0052] Further, the anti-light aging agent is a hindered amine light stabilizer, and its CAS number is 52829-07-9.

[0053] Further, the high temperature resistant flavor is vanilla flavor, its high temperature resist...

Embodiment 3

[0060] A high-flow, low-odor, scratch-resistant polypropylene material for automotive interiors, consisting of the following raw materials in parts by weight:

[0061]

[0062]Further, the polypropylene resin is selected from a high fluidity copolymerized polypropylene with a melt flow index ≥ 20g / 10min, and its product number is K9928.

[0063] Further, the modified fiber is carbon fiber.

[0064] Further, the odor adsorption masterbatch is activated carbon.

[0065] Further, the anti-scratch agent is prepared from polysiloxane and silicone in a ratio of 2:1.

[0066] Further, the toughening agent is an octene copolymer.

[0067] Further, the antioxidant is prepared from a thioester antioxidant and an ester antioxidant at a ratio of 2:1.

[0068] Further, the anti-light aging agent is a hindered amine light stabilizer, and its CAS number is 52829-07-9.

[0069] Furthermore, the high-temperature-resistant flavor is Ziyun flavor, whose high-temperature resistance is 150°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com