Acid residue treatment method

An acid residue treatment and acid residue technology, applied in the petrochemical field, can solve the problems of high viscosity of sulfuric acid residue, difficult to handle, unable to effectively reduce acid value, etc., and achieve the effect of reducing acid value, realizing economic value and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

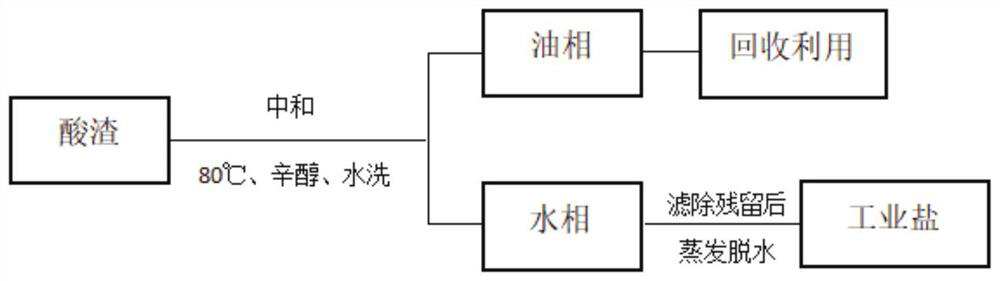

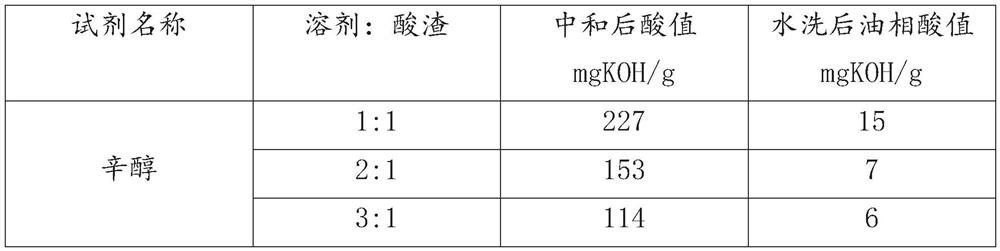

[0017] The present invention proposes a brand-new treatment method for acid slag, which detects the acid value of acid slag and calculates the amount of alkali (caustic soda, ammonia water, etc.) The acid slag is dissolved in the specially treated tank, and 1.2 equivalents of the calculated alkali amount is dissolved in water twice the mass of the acid slag, and the neutralization is carried out twice. Stop stirring for 1 hour after stirring fully, remove the water phase at the bottom, and finally wash twice with water to obtain an oil phase with an acid value of less than 10, which can be used as a raw material for blending fuel oil with other extracted oils. The neutralized water phase is filtered by air flotation and membrane treatment to remove trace organic residues, and then MVR is evaporated and dehydrated to produce industrial salt.

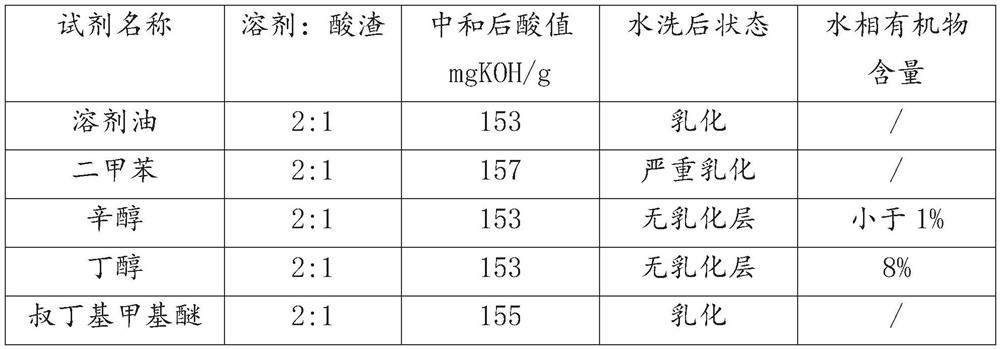

[0018] Because the acid value of the acid slag is extremely large (usually between 400-800, depending on the storage time) and a large a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com