Machining method for improving performance of AlCrN coated cutter through micro-particle shot blasting aftertreatment

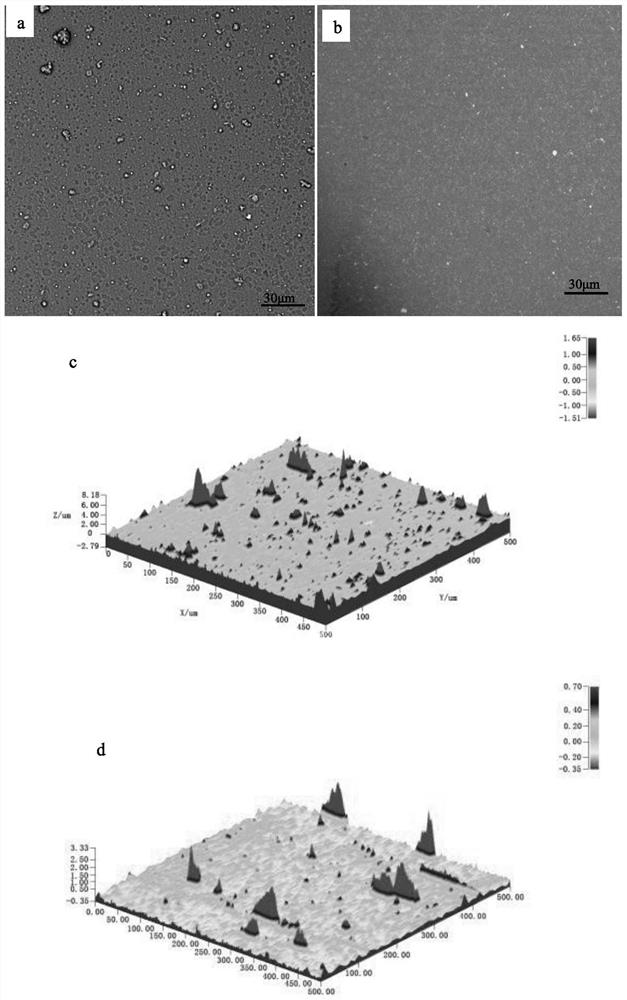

A processing method and shot peening technology, applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve the problems of reducing the overall performance of the coating, increasing the friction resistance, increasing the surface roughness of the coating, etc. Achieving the effect of low coating surface roughness, reduced number of droplet particles, and reduced coating surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The test uses M42 high-speed steel sample pieces and M42 high-speed steel straight shank end mills with a diameter of 10mm. Two symmetrically distributed AlCr (atomic ratio Al:Cr=70:30, purity 99.5%) alloy targets were used in the test. Before coating, use high-energy Ar + The surface of the substrate is bombarded, that is, the surface of the substrate is etched and cleaned, the current is 90A, and the time is 30min; when coating, the temperature is 450°C, N 2 Pressure 4.0*10 -2 mbar, the AlCr alloy target current is 130A, and the deposition time is 2 hours.

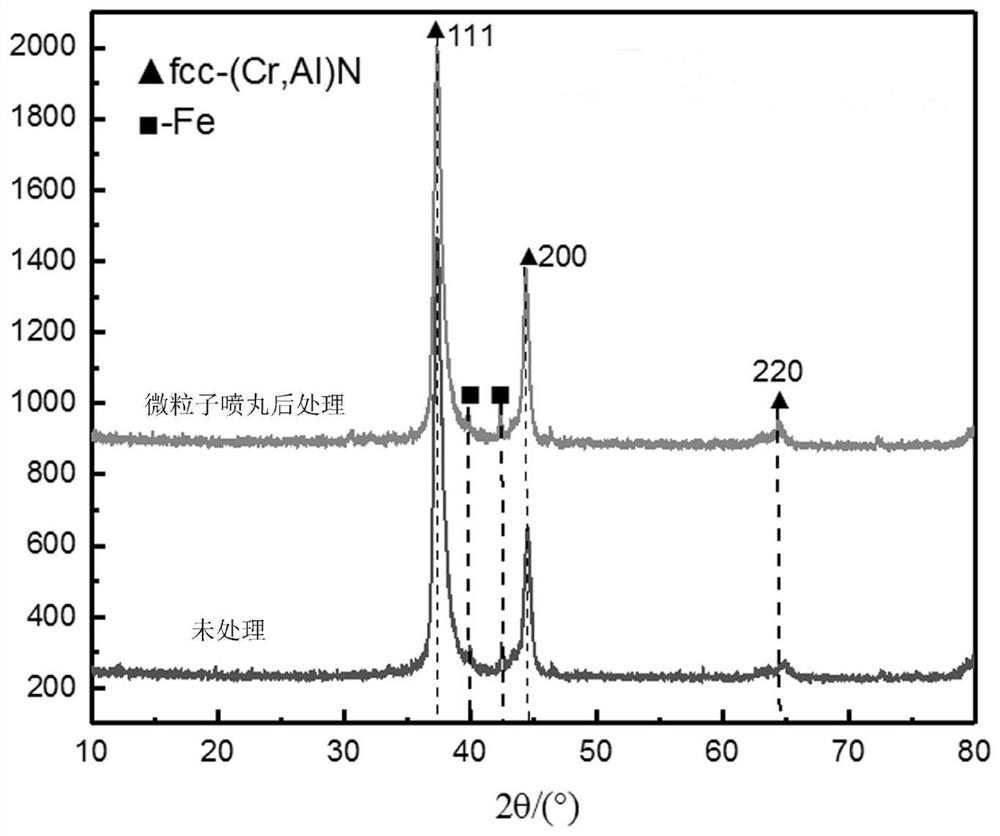

[0049] The prepared AlCrN coating was tested.

Embodiment 2

[0051] The method of preparing the AlCrN coating is the same as the first embodiment.

[0052] Micro particle peening steps:

[0053]The first step is to select microparticle pellets. The pellets are high-speed steel shot materials with a diameter of 80 μm to 150 μm. The pellets present a good spherical shape, and the hardness of the microparticles is as high as HRC 68; in the second step, the diameter of the microparticle shot peening nozzle is 5mm, the distance between the nozzle distance and the coating sample is set to 5cm~8cm; in the third step, the shot peening pressure is set to 0.55MPa, and the speed of microparticle peening is set to 150m / s; the peening time of microparticle peening is set for 30s.

[0054] The AlCrN coating after microparticle shot peening was tested.

[0055] Other implementations are the same as in Embodiment 1.

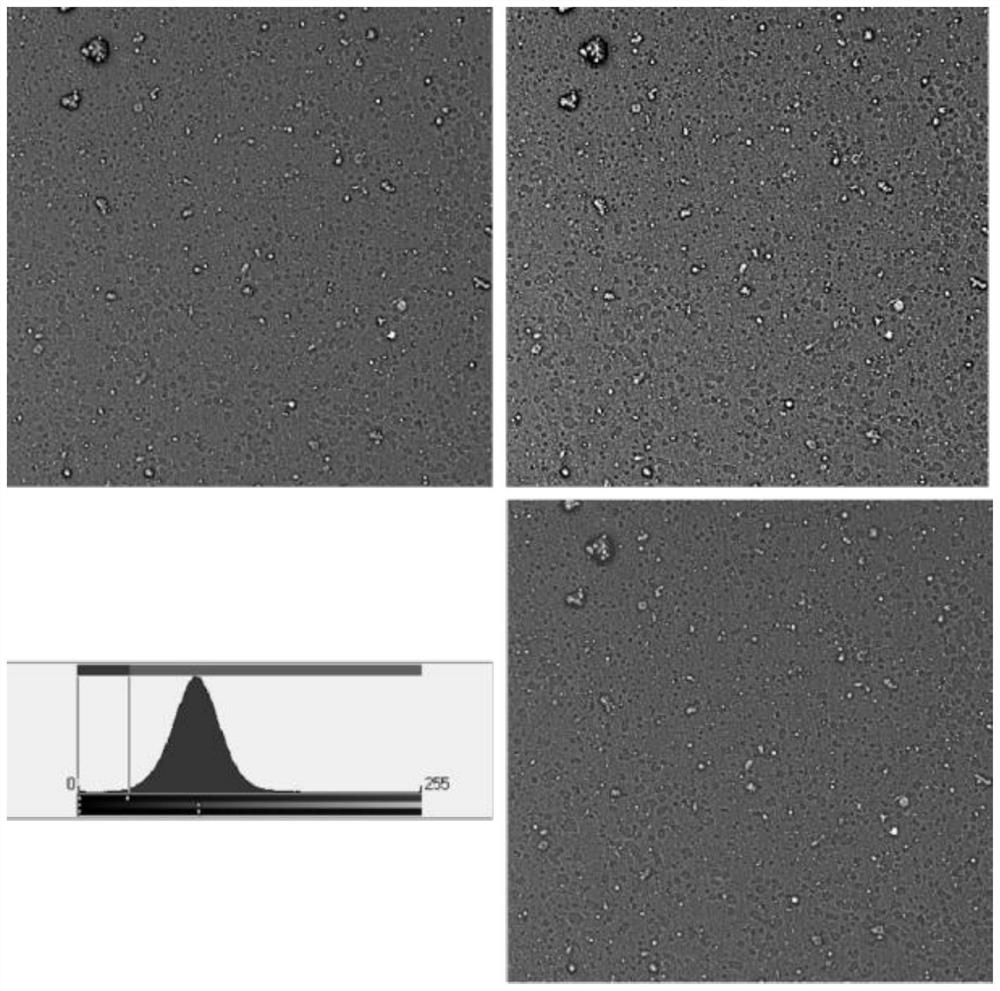

[0056] The untreated AlCrN coating and the AlCrN coating treated with particle shot peening were tested, and the test results are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com