Pig feed and preparation process thereof

A preparation process, a technology for pig feed, which can be used in the molding or processing of feed, animal feed, animal feed, etc., and can solve problems such as inability to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0035] The present embodiment is described below in conjunction with figure, a kind of preparation technology of pig feed, comprises the following steps:

[0036] Step 1: Add the ingredients to the mixing container;

[0037] Step 2: shaking and stirring the raw materials at the same time to obtain a mixed pig feed;

[0038] Step 3: Pour out the stirred pig feed and squeeze it;

[0039] Step 4: Cut the extruded pig feed into pellets;

[0040] The pig feed preparation process also involves a pig feed preparation device;

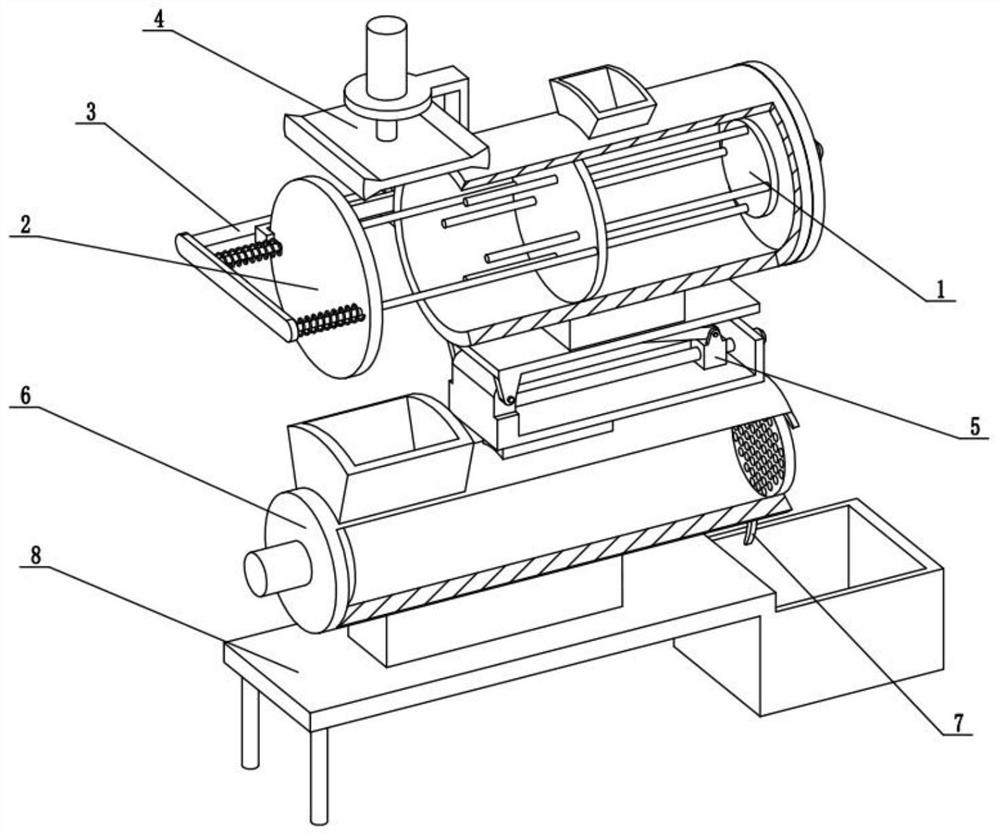

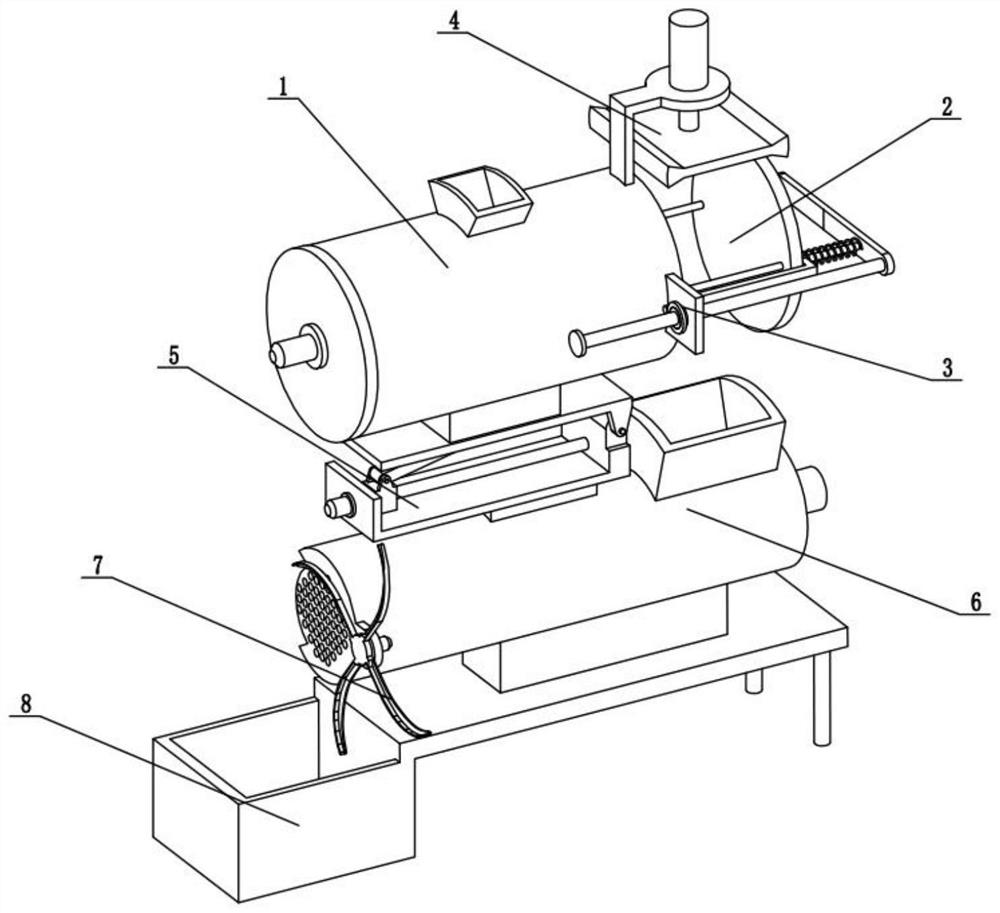

[0041]The pig feed preparation device includes a feed mixing mechanism 1, a side sealing mechanism 2, a moving drive mechanism 3, a feed cleaning mechanism 4, a tilting and shaking mechanism 5, a feed extrusion mechanism 6, a rotary cutting mechanism 7 and a collection support mechanism 8, The rotary cutting mechanism 7 is connected to the feed extruding mechanism 6, the feed extruding mechanism 6 is connected to the collection support mechanism 8, the tilti...

specific Embodiment approach 2

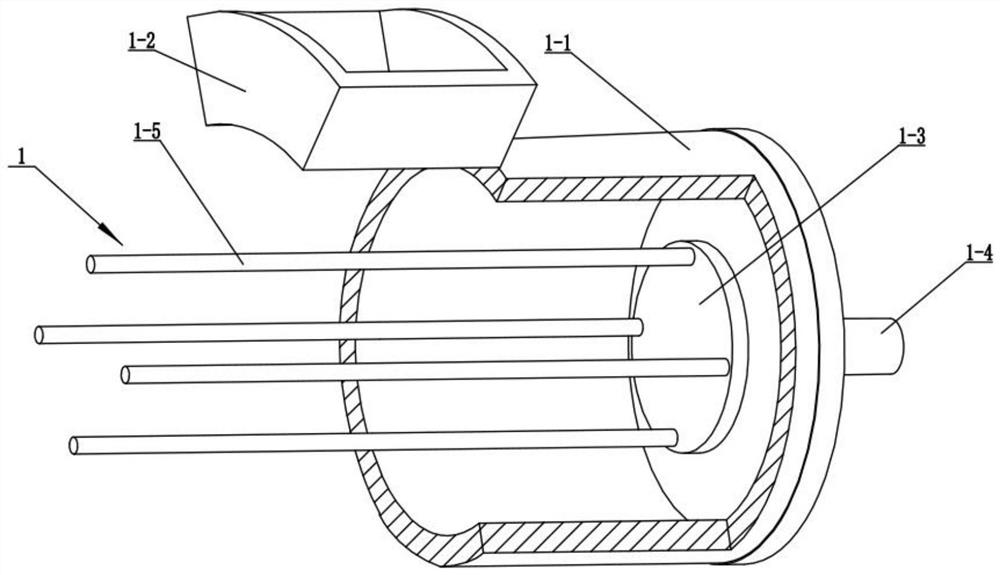

[0044] The present embodiment will be described below in conjunction with the drawings. This embodiment will further illustrate Embodiment 1. The feed mixing mechanism 1 includes a mixing bucket 1-1, a feed port 1-2, a rotating plate 1-3, and a stirring motor 1-4. and stirring rod 1-5, a plurality of stirring rods 1-5 are all fixedly connected on the rotating plate 1-3, rotating plate 1-3 is connected on the output shaft of stirring motor 1-4, and stirring motor 1-4 is fixedly connected At the right end of the mixing barrel 1-1, a feeding port 1-2 is arranged at the upper end of the mixing barrel 1-1.

[0045] Add all the raw materials into the mixing barrel 1-1 through the feed port 1-2 according to the weight parts, and then the stirring motor 1-4 drives the rotating plate 1-3 to rotate, so that the rotating plate 1-3 drives a plurality of stirring rods 1 -5 Move up, stir and mix the raw materials, so as to get evenly mixed pig feed.

specific Embodiment approach 3

[0047] This embodiment will be described below in conjunction with the drawings. This embodiment will further explain Embodiment 2. The side sealing mechanism 2 includes a scraper 2-1, a scraper hole 2-2, a connecting rod 2-3, and a blocking plate. 2-4. The moving beam 2-5 and the connecting spring 2-6, the two connecting rods 2-3 are fixedly connected to the scraper 2-1, and the scraper 2-1 is provided with a plurality of scraper holes 2 -2, the blocking plate 2-4 is fixedly connected to the two connecting rods 2-3, the moving beam 2-5 is fixedly connected to the two connecting rods 2-3, the moving beam 2-5 is connected to the blocking plate 2-4 There are two connecting springs 2-6 fixedly connected between them, multiple stirring rods 1-5 are respectively slidably connected in multiple scraping rod holes 2-2, and the scraping wall plate 2-1 is attached to the inner wall of the mixing barrel 1-1 superior.

[0048] In the initial state, the blocking plate 2-4 is attached to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com