Caffeine microcapsule, preparation method thereof and compound paracetamol preparation

A technology of caffeine and microcapsules, which is applied in the fields of preparation, caffeine microcapsules and compound paracetamol preparations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

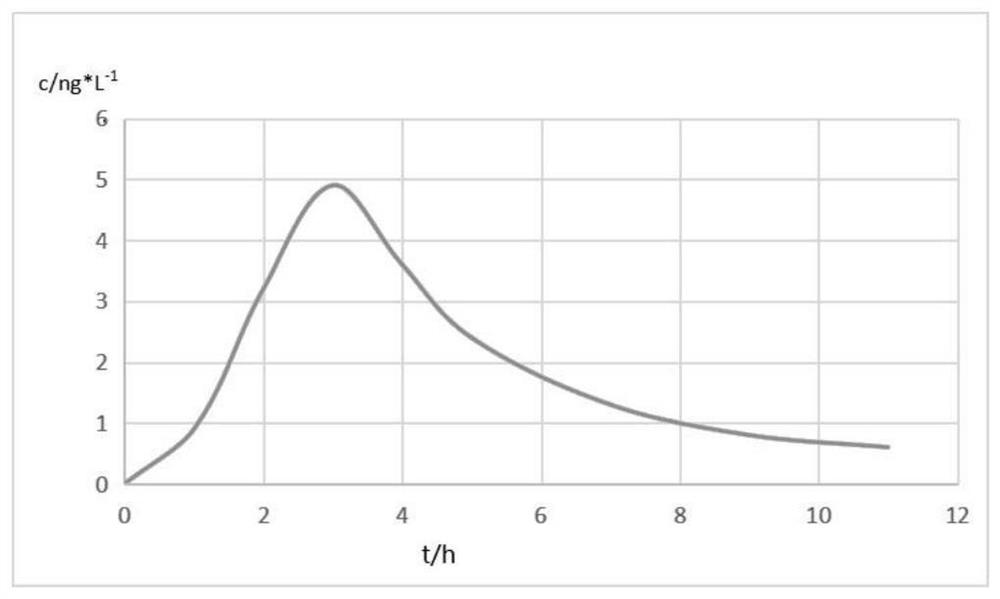

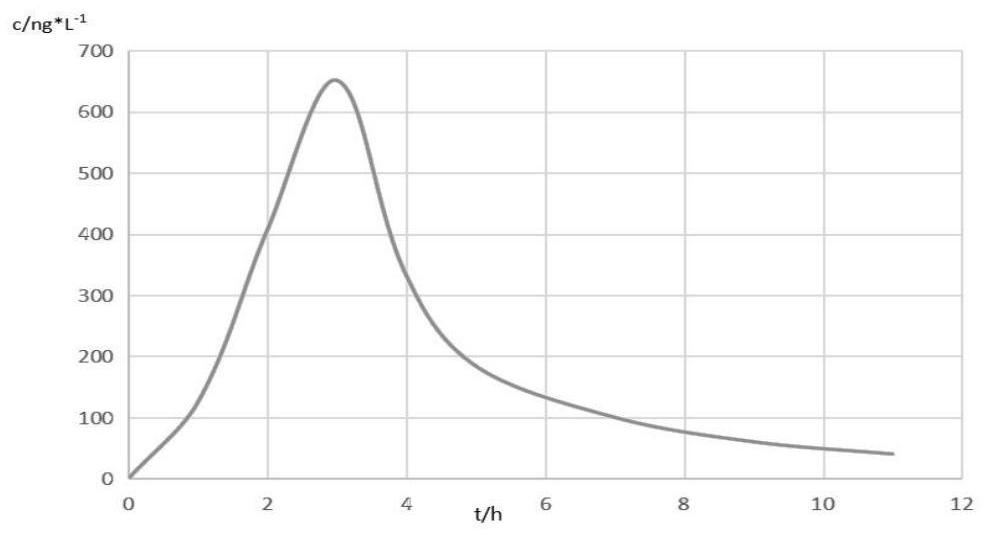

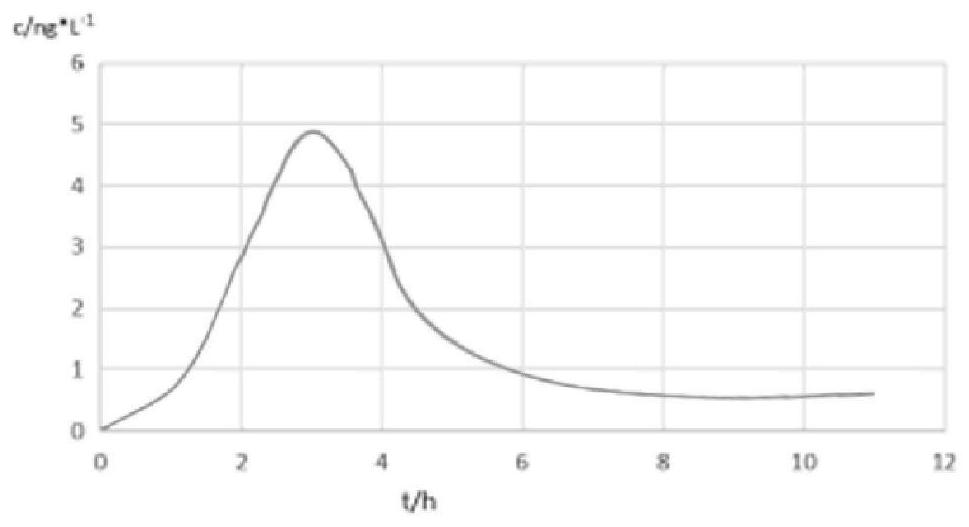

Image

Examples

Embodiment 1

[0039] The preparation of embodiment 1 microcapsule of the present invention

[0040] Heat water to 80°C, add wall material octenyl succinic esterified starch to dissolve, cool to room temperature, the mass ratio of wall material to water is 5:10, and obtain the first wall material aqueous solution;

[0041] Heat water to 80°C, add wall material to dissolve carboxymethyl cellulose, cool to room temperature, the mass ratio of wall material to water is 5:10, and obtain the second wall material aqueous solution;

[0042] The core material (caffeine) is mixed with ethanol according to the mass ratio of 5:25 to obtain the ethanol solution of the core material;

[0043]The mass ratio of caffeine to the first wall material and the second wall material is 5:1:1;

[0044] Add the ethanol solution of the core material to the aqueous solution of the first wall material to form a suspension.

[0045] Homogenize the suspension after dispersion, the pressure of the first homogenization is...

Embodiment 2

[0047] The preparation of embodiment 2 microcapsules of the present invention

[0048] Heat water to 80°C, add wall material octenyl succinic esterified starch to dissolve, and cool to room temperature, wherein the mass ratio of wall material to water is 5:10 to obtain the first wall material aqueous solution;

[0049] Heat water to 80°C, add wall material to dissolve carboxymethyl cellulose, cool to room temperature, the mass ratio of wall material to water is 1:10, and obtain the second wall material aqueous solution;

[0050] The core material and ethanol are mixed according to the mass ratio of 5:60 to obtain the ethanol solution of the core material;

[0051] The mass ratio of caffeine to the first wall material and the second wall material is 5:5:5;

[0052] Add the ethanol solution of the core material to the aqueous solution of the first wall material to form a suspension.

[0053] Homogenize the suspension after dispersion, the pressure of the first homogenization i...

Embodiment 3

[0055] The preparation of embodiment 3 microcapsules of the present invention

[0056] Heat water to 80°C, add wall material octenyl succinic esterified starch to dissolve, cool to room temperature, the mass ratio of wall material to water is 1:10, and obtain the first wall material aqueous solution;

[0057] Heat water to 80°C, add wall material to dissolve carboxymethyl cellulose, cool to room temperature, the mass ratio of wall material to water is 5:10, and obtain the second wall material aqueous solution;

[0058] The core material (caffeine) is mixed with ethanol according to the mass ratio of 25:60 to obtain the ethanol solution of the core material;

[0059] The mass ratio of caffeine to the first wall material and the second wall material is 25:1:1;

[0060] Add the ethanol solution of the core material to the aqueous solution of the first wall material to form a suspension.

[0061] Homogenize the suspension after dispersion, the pressure of the first homogenizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com