Hydrodynamic cavitation-ultrasonic cavitation-oxidation coupled process and device for cleaning and regeneration of activated carbon

A regeneration device, activated carbon technology, applied in filter regeneration, chemical/physical/physical-chemical process, chemical/physical/physical-chemical process of applying energy, etc., can solve the problem of incomplete cleaning of activated carbon, destruction of activated carbon, long time required and other problems, to achieve the effect of strong magnification, small energy attenuation, and improved cavitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

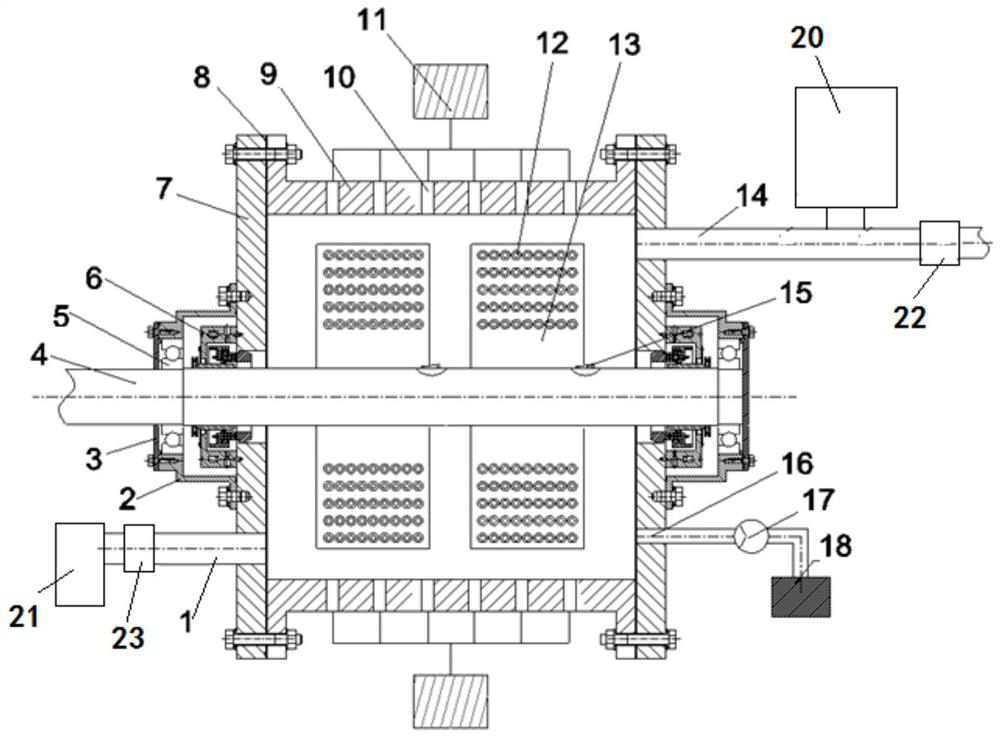

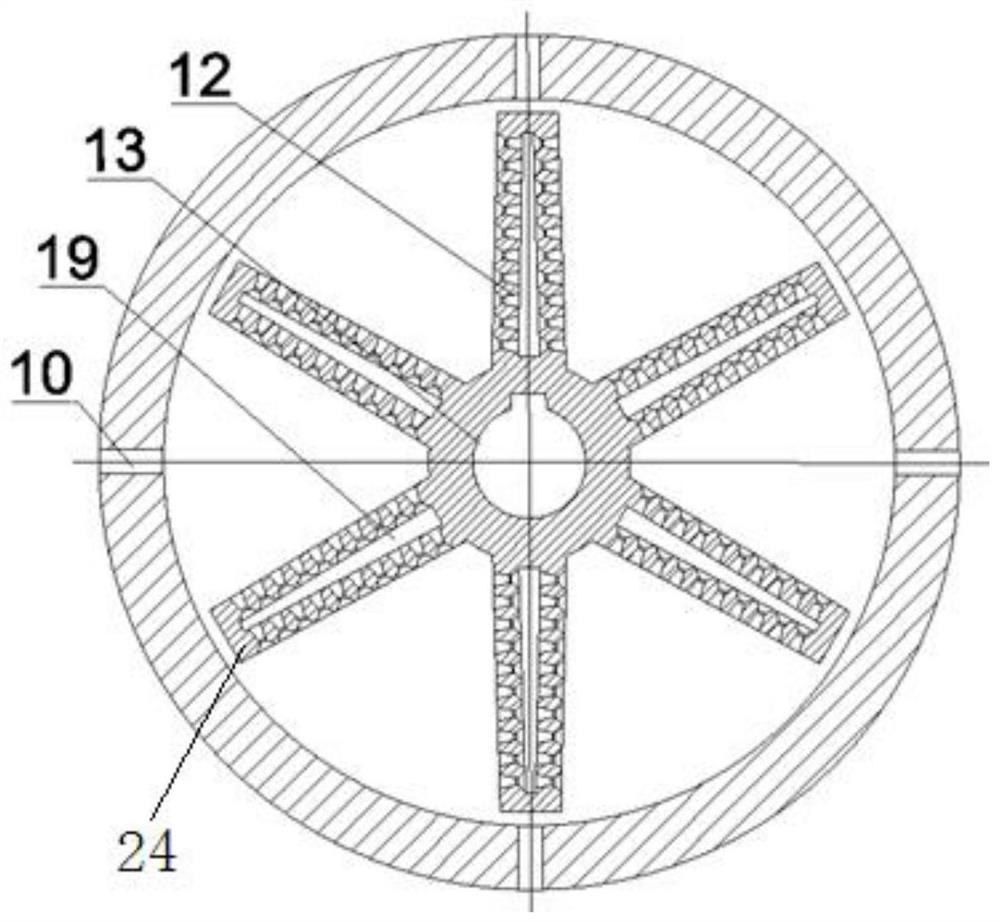

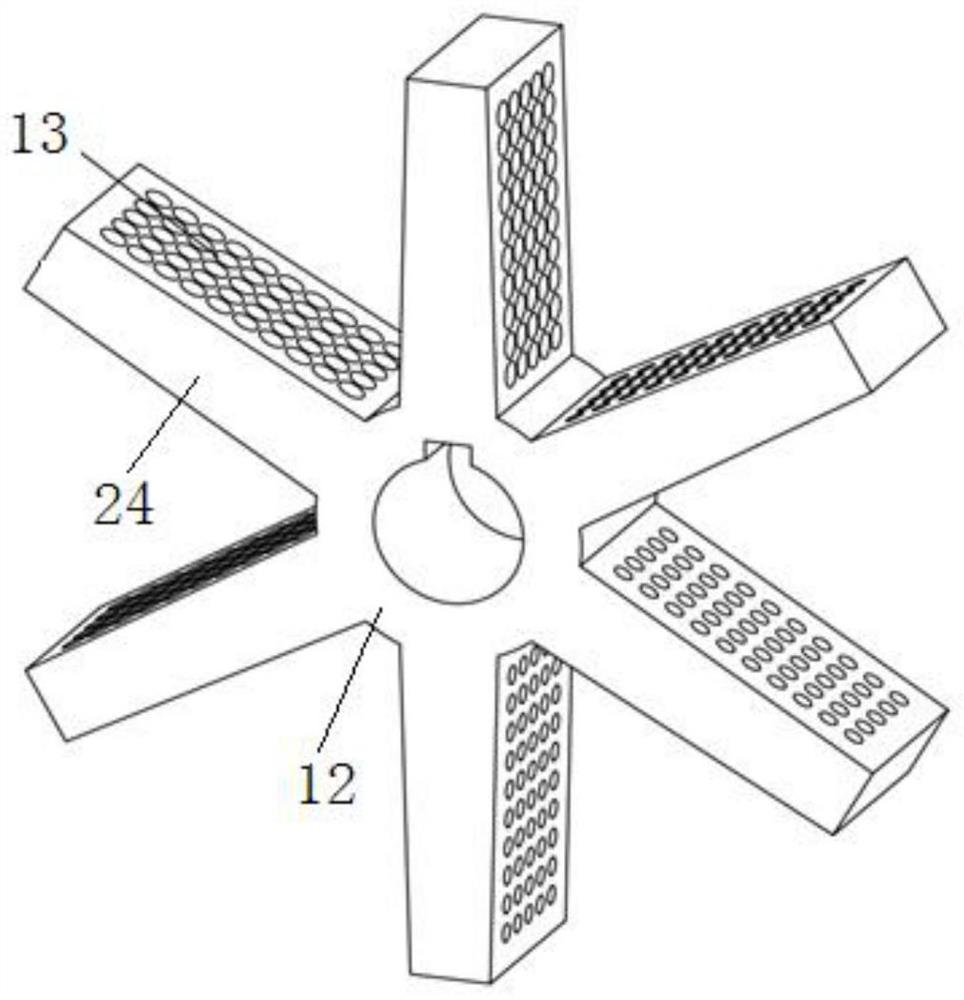

[0052] The activated carbon cleaning and regeneration device of the present invention is coupled with hydraulic cavitation, ultrasonic cavitation and advanced oxidation, and effectively combines the three processes into one. Its structure is as follows: figure 1 As shown, it includes a stator 9, a rotor 13, a rotating shaft 4, an ultrasonic transducer 10 and an oxidant injection device.

[0053] The stator 9 is a hollow sealed cylinder, the two ends are connected to the stator end cover 7 by bolts, and there is a sealing washer 8 at the connection, so that a sealed cavity is formed inside the stator 9 . The rotating shaft 4 is installed in the stator 9 through the angular contact ball bearing 5, the angular contact ball bearing 5 is arranged in the sealing cover 2, the sealing cover 2 is fixedly connected to the stator end cover 7, and the sealing end cover 3 is connected to the sealing cover 2, and There is a sealing ring at the connection, a mechanical seal 6 is arranged bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap