Sewage treatment plant virtual debugging operation method

A technology of sewage treatment plant and debugging method, which is applied in the direction of light water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., which can solve poor learning effect, increase debugging cost, and process system collapse and other issues to achieve a good training effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

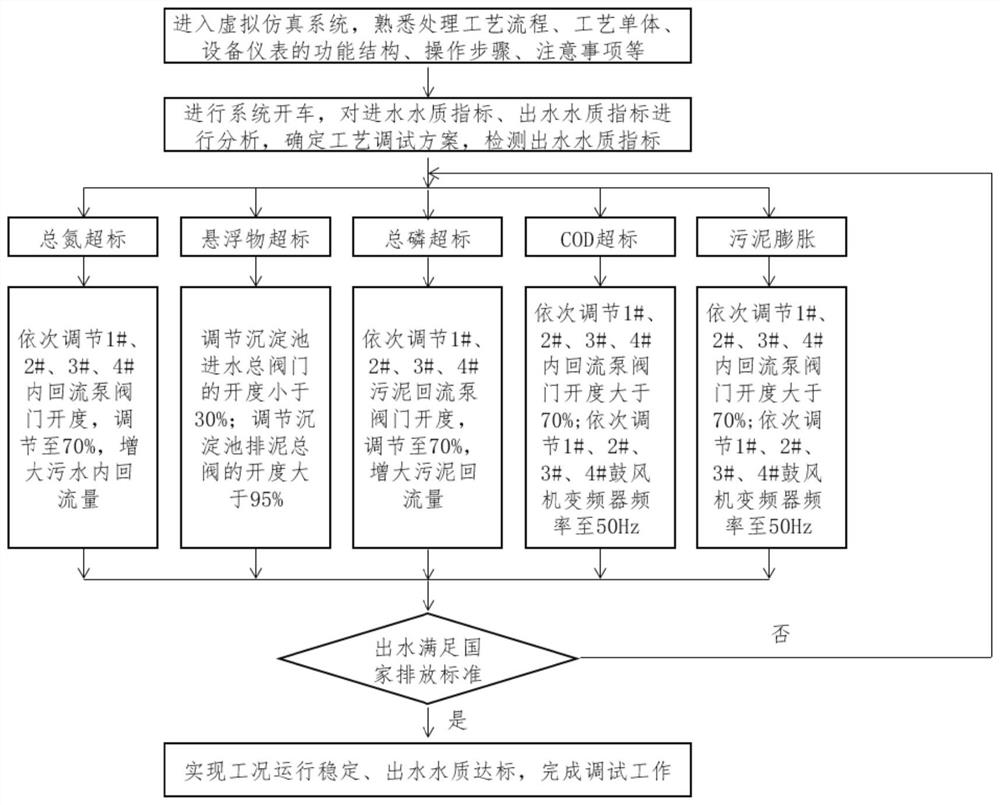

[0033] A virtual simulation debugging method for a sewage treatment plant, comprising the following steps:

[0034] S1. Modeling is carried out according to the real sewage treatment process. The treatment process unit includes grid sump, lifting pump room, grit chamber, anaerobic-anoxic-aerobic tank, filter tank, ultraviolet disinfection tank, and auxiliary buildings include comprehensive Building, central control room, laboratory, fan pump room, sludge dehydration workshop, equipment includes water pump, fan, dehydrator, grid machine, mixer, etc. Instruments include dissolved oxygen meter, pH meter, redox potential meter and Relevant valves and switches, as well as factory roads, vegetation and greening, etc., completely restore the real factory environment;

[0035] S2. Carry out system start-up in the virtual sewage treatment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com