Preparation method of weakly-alkaline-activated nickel slag high-strength concrete

A high-strength concrete and alkali-activated technology, applied in the field of concrete, can solve the problems of concrete volume stability that is difficult to control the risk of alkali-aggregate reaction, and achieve the effects of saving natural resources, increasing surface area, and strong economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

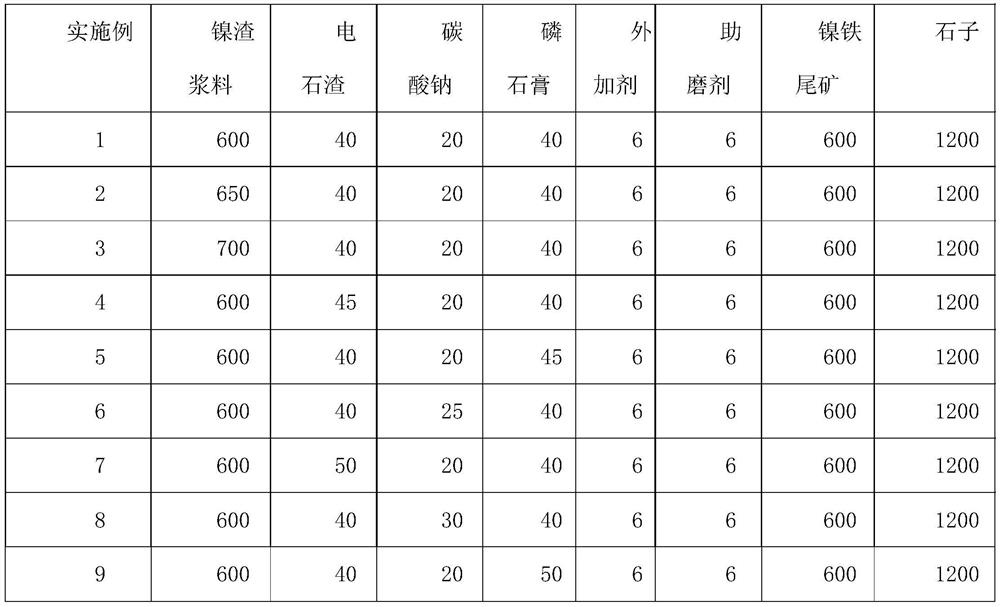

Embodiment 1

[0026] Embodiment 1: A kind of preparation method of weak base-activated nickel slag high-strength concrete of the present invention, each component is counted by weight, weighs 600 parts of wet-grinding nickel slag slurry in the above-mentioned nickel slag slurry, 40 parts of carbide slag 20 parts of sodium carbonate, 45 parts of phosphogypsum, 6 parts of admixture, and 6 parts of grinding aid are placed in a mixer and mixed for 20 seconds. Add 600 parts of ferronickel tailings and 1200 parts of stones. Excite nickel slag concrete.

Embodiment 2

[0027] Embodiment 2: A kind of preparation method of weak base excited nickel slag high-strength concrete of the present invention, each component counts by weight, weighs 650 parts of wet-grinding nickel slag slurry, 40 parts of carbide slag in the above-mentioned nickel slag slurry 20 parts of sodium carbonate, 45 parts of phosphogypsum, 6 parts of admixture, and 6 parts of grinding aid are placed in a mixer and mixed for 20 seconds. Add 600 parts of ferronickel tailings and 1200 parts of stones. Excite nickel slag concrete.

Embodiment 3

[0028]Embodiment 3: A kind of preparation method of weak base stimulated nickel slag high-strength concrete of the present invention, each component counts by weight, weighs 700 parts of wet-grinding nickel slag slurry, 40 parts of carbide slag in the above-mentioned nickel slag slurry 20 parts of sodium carbonate, 45 parts of phosphogypsum, 6 parts of admixture, and 6 parts of grinding aid are placed in a mixer and mixed for 20 seconds. Add 600 parts of ferronickel tailings and 1200 parts of stones. Excite nickel slag concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com