Polypropylene compound as well as application and preparation method thereof

A technology of polypropylene and composites, applied in the field of polypropylene composites and its application and preparation, can solve the problems of no improvement in surface hardness, low surface hardness, surface scratches, etc., and achieve scratch resistance and good mechanical synthesis Performance, the effect of improving scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

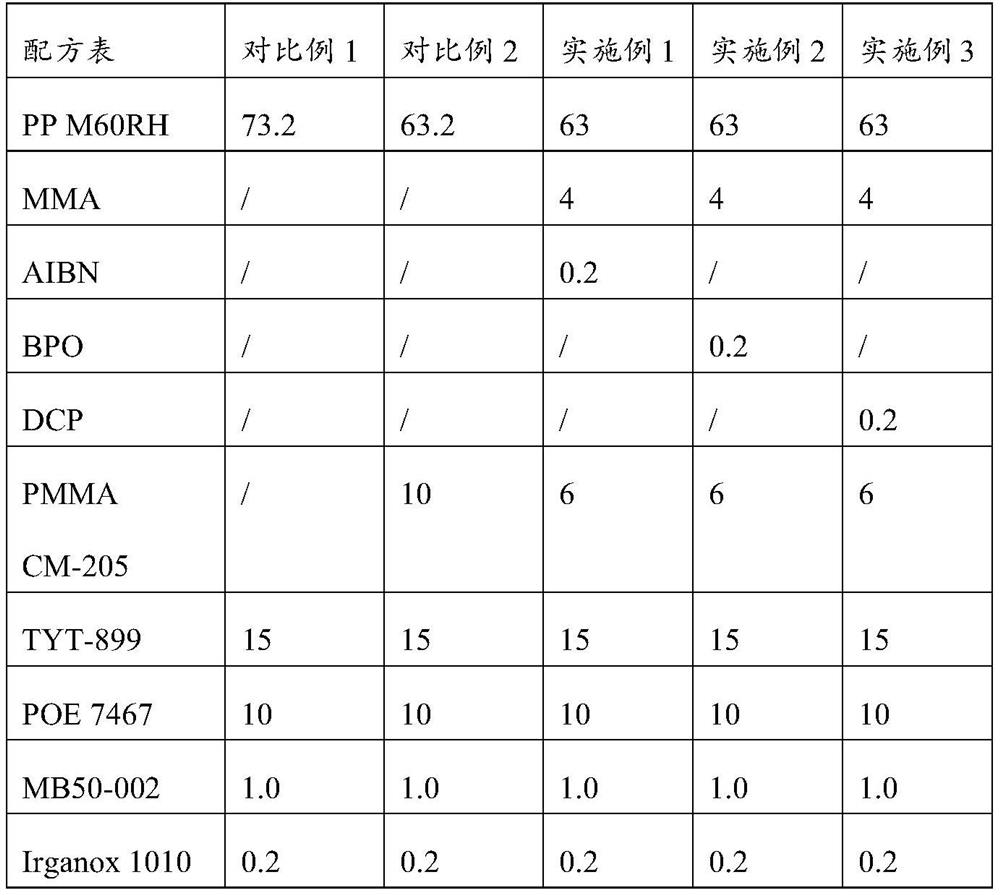

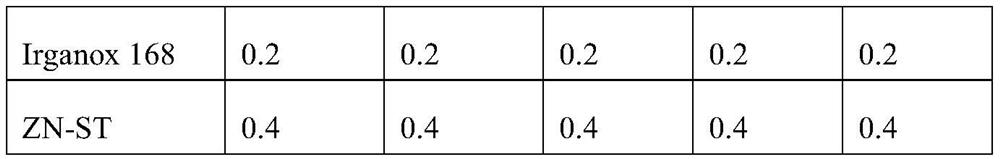

Embodiment 1

[0037] The extruder used in the preparation is a two-stage twin-screw extruder, and the reaction extrusion is carried out in the first-order space of the twin-screw extruder. The length-to-diameter ratio is 48:1, and the second-order space of the twin-screw extruder is For physical blending, the length-to-diameter ratio is 30:1. Of course, it can also be the length-to-diameter ratio of other parameter values.

[0038] 1) Reactive extrusion: 46.7 parts by weight of polypropylene resin PPM60RH is added from the main feed, 0.1 part by weight of azobisisobutyronitrile AIBN free radical initiator is dissolved in 1 part by weight of methyl methacrylate and added through a liquid metering pump , Carry out grafting reaction in the first stage space of the twin-screw extruder to generate polypropylene grafted methyl methacrylate copolymer, and then extrude and granulate.

[0039]2) Blending: 5 parts by weight of PMMACM-205, 10 parts by weight of talc TYT-899, 5 parts by weight of elast...

Embodiment 2

[0041] The extruder used in the preparation is a double-stage twin-screw extruder, and reactive extrusion is performed in the first-order space of the twin-screw extruder, with an aspect ratio of 48:1, and the second-order space of the twin-screw extruder is Physically blended with an aspect ratio of 30:1.

[0042] 1) Reactive extrusion: 78.1 parts by weight of polypropylene resin PPM60RH is added from the main feed, and 0.3 parts by weight of benzoyl peroxide BPO radical initiator is dissolved in 5 parts by weight of methyl methacrylate and added through a liquid metering pump, The grafting reaction was carried out in the first stage space of the twin-screw extruder to produce polypropylene grafted methyl methacrylate copolymer, which was then extruded and pelletized.

[0043] 2) Blending: mix 10 parts by weight of PMACM-205, 20 parts by weight of talc TYT-899, 15 parts by weight of elastomer POE7467, 2 parts by weight of silicone scratch agent MB50-002, and 0.25 parts by wei...

Embodiment 3

[0045] The extruder used in the preparation is a double-stage twin-screw extruder, and reactive extrusion is performed in the first-order space of the twin-screw extruder, with an aspect ratio of 48:1, and the second-order space of the twin-screw extruder is Physically blended with an aspect ratio of 30:1.

[0046] 1) Reactive extrusion: 63 parts by weight of polypropylene resin PPM60RH was added from the main feed, and 0.2 parts by weight of dicumyl peroxide DCP radical initiator was dissolved in 4 parts by weight of methyl methacrylate and added through a liquid metering pump , carry out the grafting reaction in the first-order space of the twin-screw extruder to generate polypropylene grafted methyl methacrylate copolymer, and then extrude and granulate.

[0047] 2) Blending: 6 parts by weight of PMMACM-205, 15 parts by weight of talc TYT-899, 10 parts by weight of elastomer POE7467, 1 part by weight of silicone scratch agent MB50-002, 0.2 part by weight of hindered phenoli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com