High-strength modified asphalt resistant to high temperature and low temperature and production method thereof

A modified asphalt, high and low temperature resistant technology, used in building thermal insulation materials, building components, buildings, etc., can solve problems such as hidden dangers left by road maintenance, inability to adapt to colder places, and inability to withstand winter temperatures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example is to prepare a high-strength modified asphalt resistant to high and low temperature, and the specific operation is as follows:

[0028] 100 tons of PG76-22 modified asphalt is rapidly raised from the raw material tank to 180°C through a plate heat exchanger, pumped into a 150-ton finished product tank, and 12 tons of Xinjiang Karamay rock asphalt is slowly added to the finished product tank through a conveyor , start stirring, heat and keep the temperature at 170-180°C, and control the feeding time for 3-4 hours. After the feeding is completed, continue stirring for 2 hours, add 0.8 tons of C9 petroleum resin and 0.5 tons of BN500A polyethylene wax PE, and continue stirring for 4 hours. Hours, the high-strength modified asphalt is prepared for future use.

Embodiment 2

[0030] This example is also to prepare a high-strength modified asphalt resistant to high and low temperature, and the specific operation is consistent with Example 1:

[0031] 100 tons of PG76-22 modified asphalt is rapidly raised to 180°C through a plate heat exchanger from the raw material tank, pumped into a 150-ton finished product tank, and 14 tons of Buton rock asphalt is slowly added to the finished product tank through a conveyor , start stirring, heat and keep the temperature at 170-180°C, and control the feeding time at 3-4 hours. After the feeding is completed, continue stirring for 2 hours, add 1.2 tons of C5 petroleum resin and 0.6 tons of BN500 polyethylene wax PE, and continue stirring for 3 Hours, the high-strength modified asphalt is prepared for future use.

Embodiment 3

[0033] This example is also to prepare a high-strength modified asphalt resistant to high and low temperature, and the specific operation is also consistent with Example 1:

[0034] 100 tons of PG76-22 modified asphalt is rapidly raised from the raw material tank to 180°C through a plate heat exchanger, pumped into a 150-ton finished product tank, and 13 tons of Buton rock asphalt is slowly added to the finished product tank through a conveyor , start stirring, heat and keep the temperature at 170-180°C, and control the feeding time at 3-4 hours. After the feeding is completed, continue to stir for 2 hours, add 1.0 tons of C5 / C9 copolymer resin and 1.0 tons of BN250 polyethylene wax PE, and continue Stir for 4 hours to prepare high-strength modified asphalt for future use.

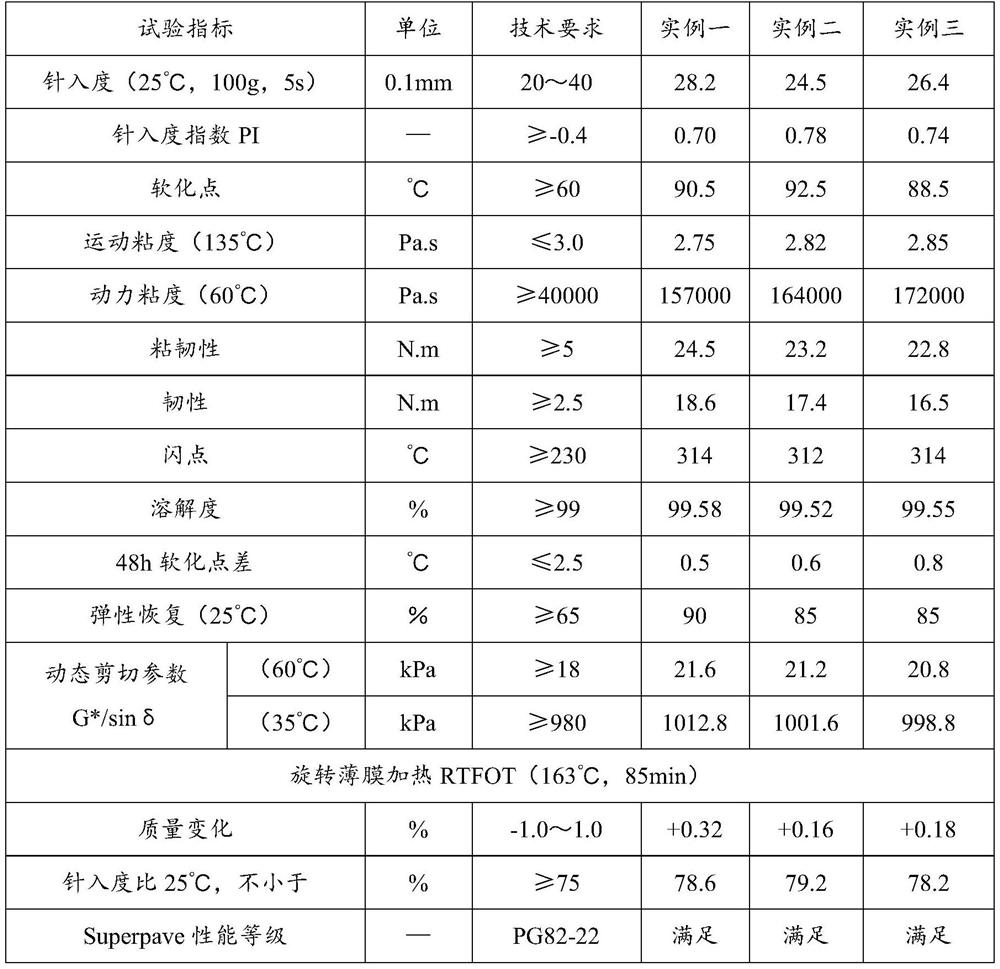

[0035] Embodiment 4 effect example

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com