Water-based colored light-cured paint and preparation method thereof

A technology of colored light and curing paint, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as human injury, large impact on human body and environment, and environmental pollution, and achieve strong adaptability, stable quality, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a kind of preparation method of water-based colored photocurable paint, comprises the following steps:

[0035] 1) Preparation of water-based special matting and wear-resistant wax slurry, check whether the state of the applicable high-speed mixer is normal, if it is in good condition, pump deionized water into the mixing tank, adjust the speed of the disperser to 300r / min, and slowly put in the modified PE wax Powder, adjust the speed to 1500r / min, seal and stir for 120min, add deionized water and clean the inner wall of the tank, stir for 10min, send for inspection, test the fineness and viscosity of water-based special matting and wear-resistant wax slurry, and put it into a special storage tank for standby after passing the test ;

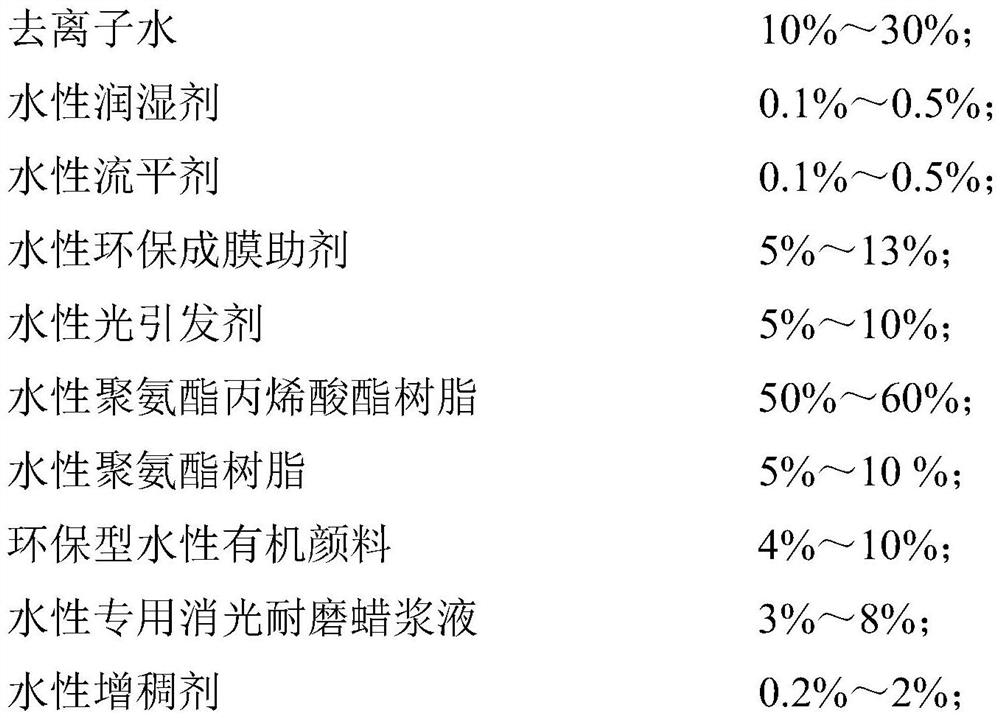

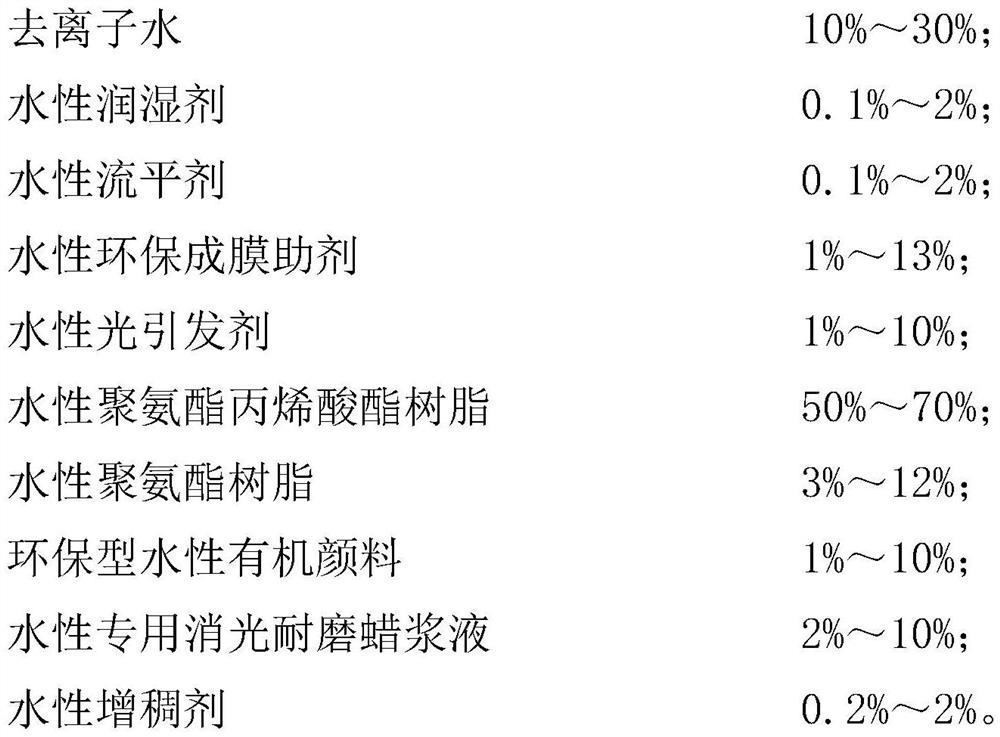

[0036] 2) Preparation of finished water-based photocurable black paint, pre-dispersion of ingredients, cleaning of special production material tanks, in the case of checking the accuracy of the materia...

Embodiment 1

[0042] 1) Preparation of water-based special matting and wear-resistant wax slurry, check whether the state of the applicable high-speed mixer is normal, if it is in good condition, pump deionized water into the mixing tank, adjust the speed of the disperser to 300r / min, and slowly put in the modified PE wax Powder, adjust the speed to 1500r / min, seal and stir for 120min, add deionized water and clean the inner wall of the tank, stir for 10min, send for inspection, test the fineness and viscosity of water-based special matting and wear-resistant wax slurry, and put it into a special storage tank for standby after passing the test ;

[0043] 2) Preparation of finished water-based light-cured black paint, pre-dispersion of ingredients, cleaning of special production material tanks, in the case of checking that the material product number is accurate, 10% by weight of deionized water, 0.1% by weight of water-based moisturizer Wet agent, 0.1% by weight of water-based leveling agen...

Embodiment 2

[0048] 1) Preparation of water-based special matting and wear-resistant wax slurry, check whether the state of the applicable high-speed mixer is normal, if it is in good condition, pump deionized water into the mixing tank, adjust the speed of the disperser to 300r / min, and slowly put in the modified PE wax Powder, adjust the speed to 1500r / min, seal and stir for 120min, add deionized water and clean the inner wall of the tank, stir for 10min, send for inspection, test the fineness and viscosity of water-based special matting and wear-resistant wax slurry, and put it into a special storage tank for standby after passing the test ;

[0049] 2) Preparation of finished water-based light-cured black paint, pre-dispersion of ingredients, cleaning of special production material tanks, in the case of checking that the material product number is accurate, 30% by weight of deionized water, 2% by weight of water-based emulsifier Wet agent, 2% by weight of water-based leveling agent, 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com