Method and application of bifidobacteria, especially a12 fermentation for preparing aldehyde flavors

A technology of bifidobacteria and aldehydes, applied in the field of biological fermentation, can solve the problems of food safety objection, environmental pollution, toxic synthetic raw materials, etc., and achieve the effect of safety guarantee and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

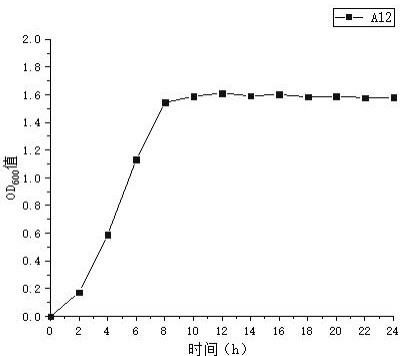

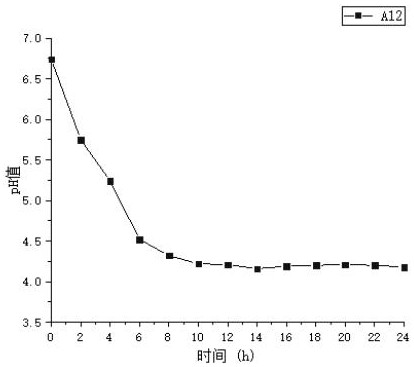

Image

Examples

Embodiment approach

[0024] According to a preferred embodiment of the present invention, the fermentation is preferably solid-state fermentation. The "solid-state fermentation" refers to fermentation under non-liquid phase conditions, and the solid-state fermentation can be a complete solid-state fermentation (for example, the fermentation method of microorganisms on a solid substrate without or substantially without free water, gas, liquid, Solid three-phase coexistence), can also be semi-solid fermentation.

[0025] According to the present invention, the consumption of each component in the culture medium can be changed in a relatively wide range. Preferably, in order to further increase the output of aldehyde fragrances, the consumption of animal fat is 10-25 parts by weight relative to animal protein. parts by weight (for example, can be 10 parts by weight, 12 parts by weight, 14 parts by weight, 16 parts by weight, 18 parts by weight, 20 parts by weight, 22 parts by weight, 24 parts by weig...

Embodiment 1-5

[0081] (1) Raw material processing: select fresh meat, remove fascia, separate lean meat and fat, mix according to the ratio in Table 2, and then pump it with a vacuum machine for later use.

[0082] (2) Ingredients: Weigh salt, sugar, glucose, soybean protein isolate, carrageenan, sodium tripolyphosphate and water according to Table 2, and mix well with the processed meat in (1).

[0083] (3) Inoculate the starter: the prepared Bifidobacterium CGMCC No. 17308 bacterial suspension (10 10 CFU / ml) inoculated into (2) according to the inoculum amount in Table 2 and chopped evenly.

[0084] (4) Put the material chopped and mixed evenly in step (3) into a closed container that has been sterilized in advance, and then set the parameters in the constant temperature and humidity drying box, and then carry out fermentation and cultivation.

[0085] Table 2

[0086]

Embodiment 6

[0088] The preparation of aldehyde spices was carried out according to the method of Example 1, except that the soybean protein isolate was replaced by an equal amount of wheat protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com