Electrolytic etching production line

A technology of electrolytic etching and production line, which is applied in the direction of electrolytic process and electrolytic components, etc. It can solve the problems of poor electrolysis and development effect of the anode plate, uneven solution density, inability to soak the anode plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

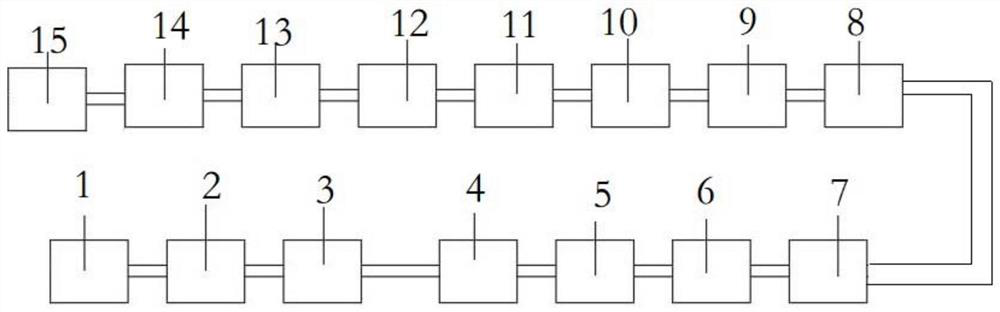

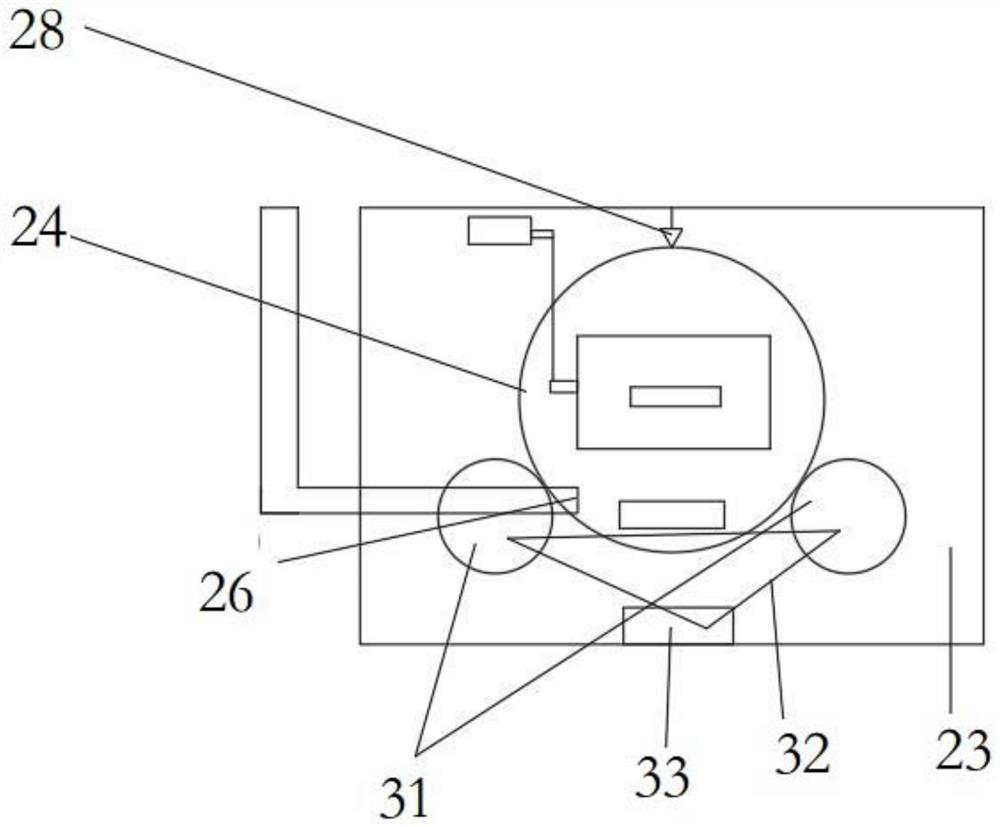

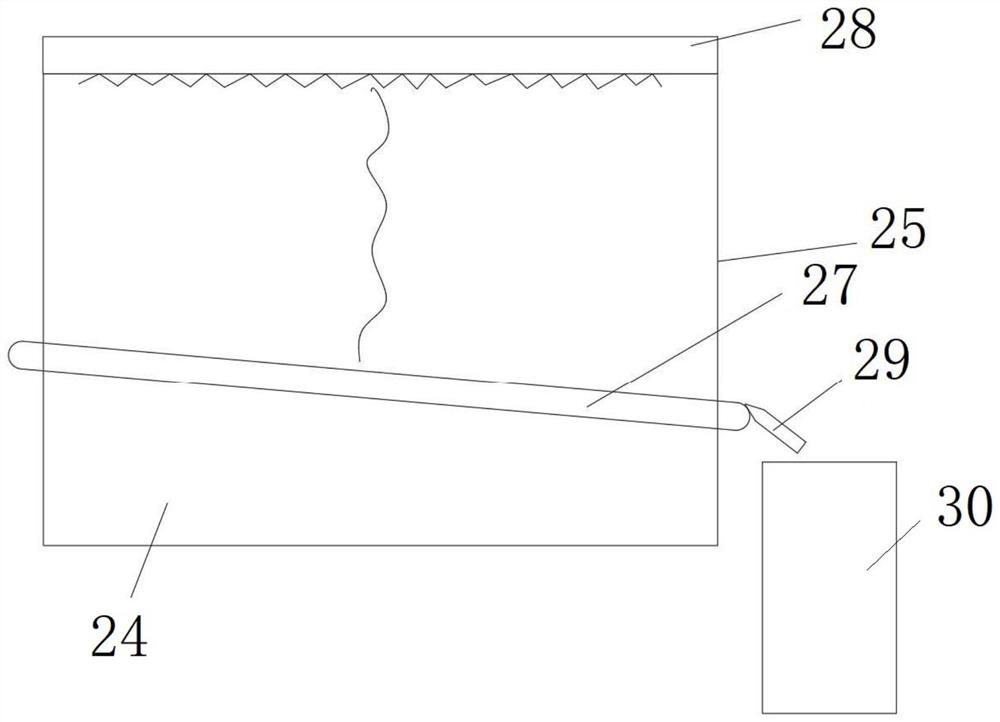

[0058] This embodiment records a kind of electrolytic etching production line, is used for carrying out electrolytic etching to anode plate, see Figure 1-Figure 9 , the production line includes a frame (not shown in the figure), on which at least a loading area 1, a developing area, an electrolysis area and a blanking area 15 are set, wherein the anode plate is loaded in the loading area 1, specifically In order for the anode plate to be clamped by the first conveying mechanism to complete the feeding action, the anode plate is removed from the first conveying mechanism in the unloading area 15, at least one developing tank 2 is set in the developing area, and at least one developing tank 2 is set in the electrolysis area. An electrolytic tank 6, the adjacent electrolytic tank 6 and the developing tank 2 are sealed and communicated, and the anode plate is clamped by the first conveying mechanism (not shown in the figure) and then driven by the first conveying mechanism, it can...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap